Steel bar truss deck hanging support device and assembling and manufacturing method thereof

A technology of steel bar truss and manufacturing method, which is applied in the direction of construction, building structure, and building material processing, etc., which can solve problems such as construction period delay, and achieve the effects of easy operation, high construction efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

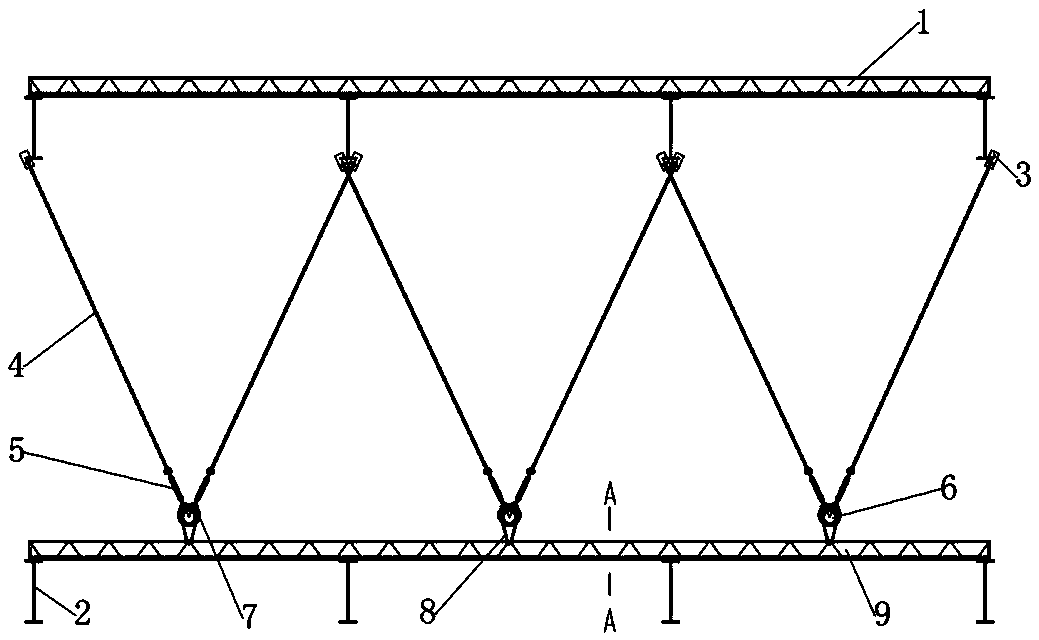

[0029] like Figure 1~3 As shown, the steel bar truss floor deck hanging device of the present invention includes the hanging plate 3 arranged on the steel beam 2 of the upper steel bar truss floor deck 1, the steel pipe 6 arranged on the lower steel bar truss floor deck 9 and the connecting hanging plate steel wire rope 4 with plate 3 and steel pipe 6 .

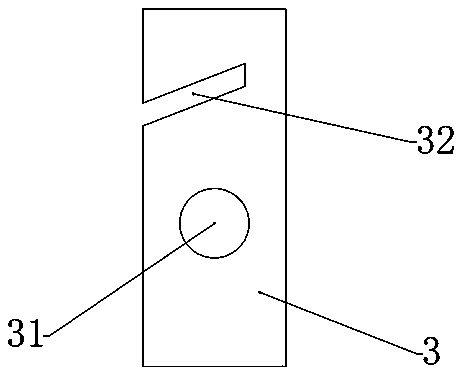

[0030] A circular hole 31 and an oblique groove 32 are provided on the hanging plate 3 , and the oblique groove 32 is located above the circular hole 31 . The hanging plate 3 is hung on the lower flange of the steel beam 2 of the upper steel bar truss floor deck 1 via the oblique groove 32 . The angle of the oblique groove 32 can be adjusted according to the position of the lower flange hanging on the upper steel beam 2, and its depth can also be adjusted according to the length of the lower flange.

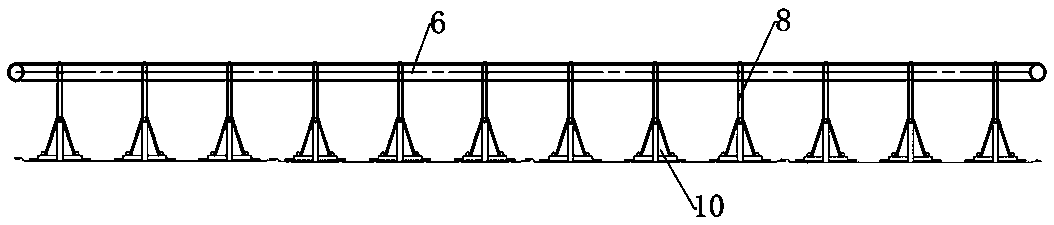

[0031] The steel pipe 6 is arranged above the steel bar trusses 10 of the lower steel bar truss floor deck 9 , preferably, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap