Cement-injecting plugging device

A plug, cement injection technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc., to ensure the effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

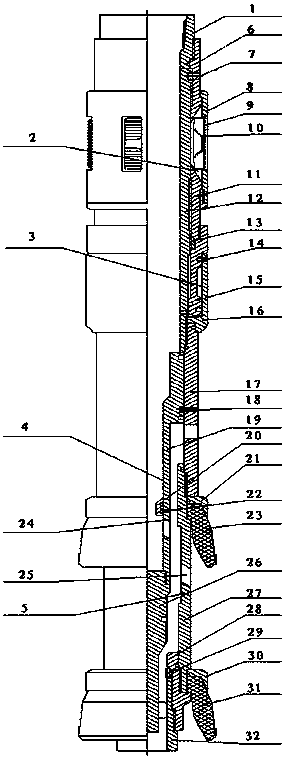

[0019] The detailed description and technical content of the present invention are described below with the drawings, but the drawings are only for reference and description, and are not used to limit the present invention.

[0020] Such as figure 1 As shown, the cement injection occluder is composed of an upper joint 1 , a suspension device 2 , a setting device 3 , an inner filling and blocking device 4 , and an outer filling and sealing device 5 . The suspension device 2 and the setting device 3 are connected up and down and set on the central pipe 12 at the same time, the upper end of the outer filling and sealing device 5 is connected to the lower end of the central pipe, and the inner filling and blocking device 4 is located inside the outer filling and packing device 5 .

[0021] Suspension device 2 is made up of upper cone 6, unsealing pin 7, slip tube 8, slips 9, leaf spring 10, lower cone 11, and central tube 12. Among them, the slip tube 8 is provided with a slot wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com