High-efficiency dust-removing equipment

A dust removal equipment and high-efficiency technology, applied in electrostatic effect separation, dispersed particle filtration, solid separation and other directions, can solve the problems of affecting self-cleaning effect, unbalanced swing strength, etc., and achieve stable connection, cost saving, and shortened interval. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

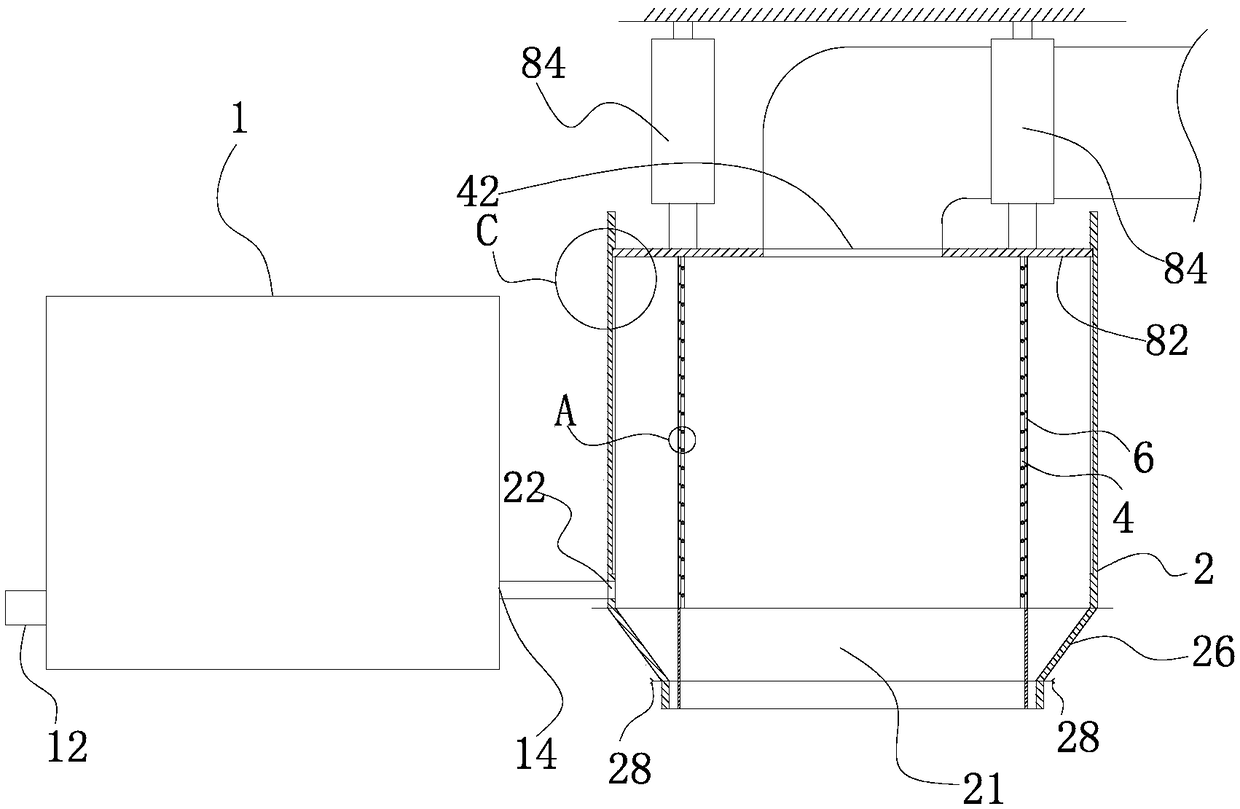

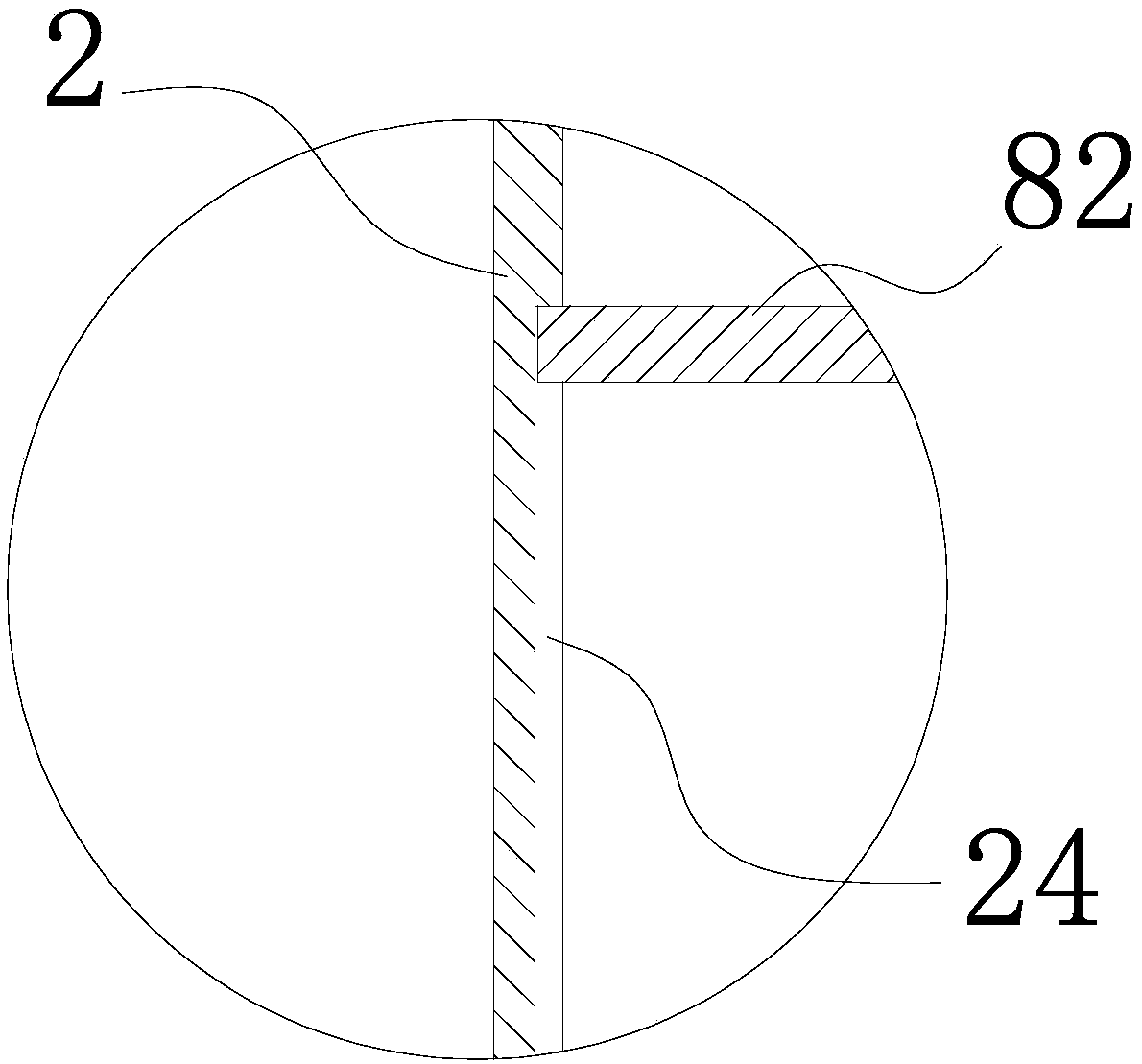

[0050] like Figure 1-5 As shown, a high-efficiency dust removal equipment includes a dust removal cylinder 2, a bag cylinder 4 arranged in the dust removal cylinder 2, an air inlet 22 connected to the dust removal cylinder 2 and an air outlet 42 connected to the bag cylinder 4, and It includes several telescopic brackets 6 arranged on the side of the bag cylinder 4 and capable of driving the bag cylinder 4 to compress or restore as a whole.

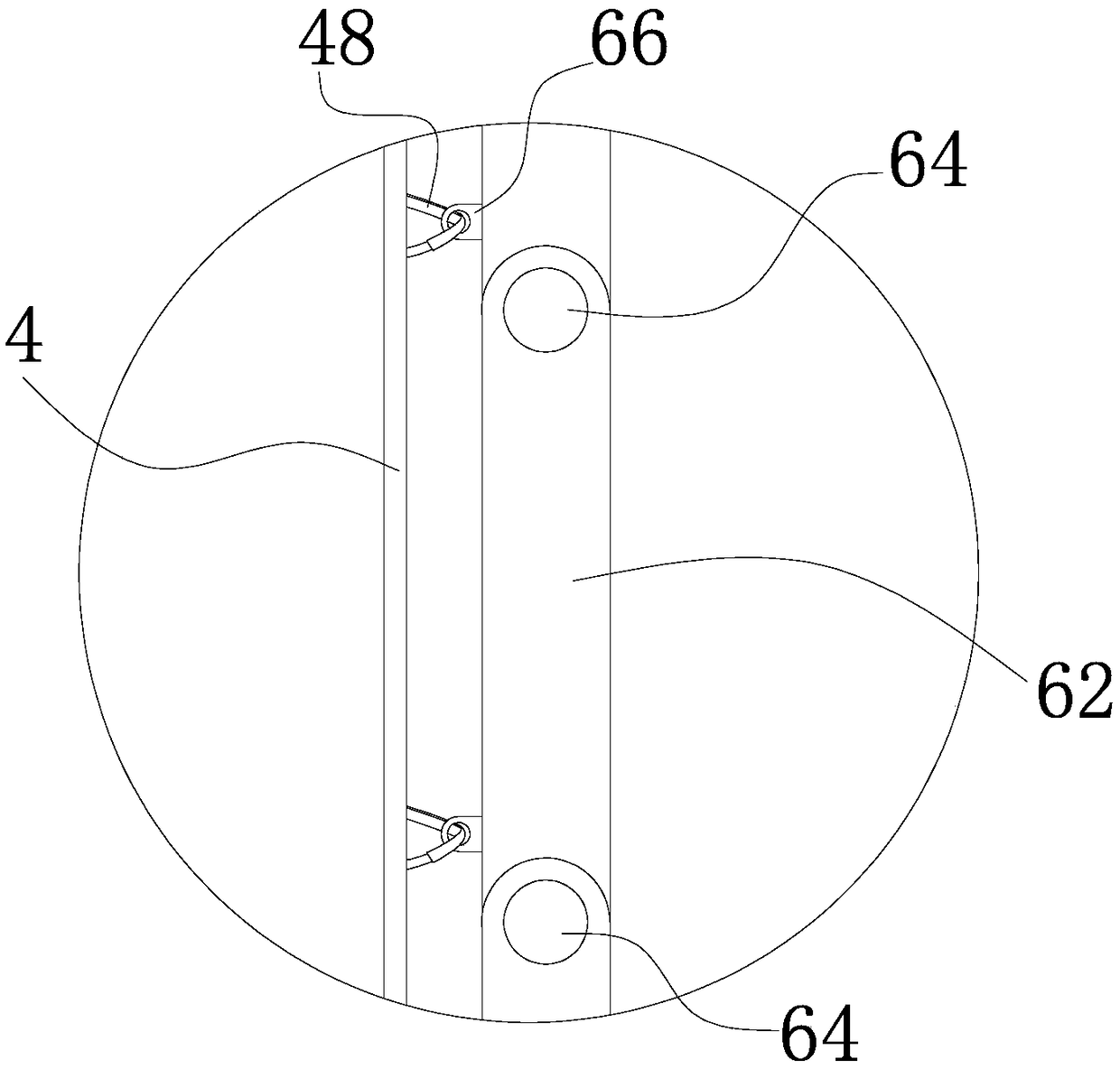

[0051] Specifically, the telescopic support 6 and the bag cylinder 4 are fixed at multiple points at equal intervals in the axial direction. The telescopic bracket 6 is formed by hinged end to end of a plurality of rod-shaped units 62 to form a plurality of hinge points 64 . The bag cylinder 4 has alternate wavy creases with mountain folds and valley folds extending axially, and the distance between adjacent mountain folds and valley folds on the bag cylinder 4 is 1 / 3 of the axial height of the bag cylinder 4 in a straightened state. 4...

Embodiment 2

[0061] like Figure 2-6 As shown, the difference between the high-efficiency dust removal equipment of the present invention and Embodiment 1 is that it includes two sets of dust removal cylinders 2 capable of working independently and corresponding bag cylinders 4, and the first-stage air outlet 14 of the electrostatic precipitator 1 is divided into two The roads are respectively connected to the air inlets 22 of the two dust removal cylinders 2, and the two roads are respectively provided with valves 86 to control on-off.

[0062] During operation, the flue gas to be treated still enters from the primary air inlet 12, and after being treated by the electrostatic precipitator 1, it enters the two dust removal cylinders 2 through the corresponding air inlets 22 for further filtration. In each dust removal cylinder 2, the flue gas enters the interior from the outside of the bag cylinder 4, and then is discharged upward through the air outlet 42 to complete the entire dust remov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com