Bearing collar production line with medium-frequency induction heating furnace and working method of bearing collar production line

The technology of induction heating furnace and induction heating coil is applied in the field of bearing manufacturing, which can solve the problems of low efficiency and uneven heating of medium frequency induction heating furnace, and achieve the effect of reducing labor intensity, improving production efficiency and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

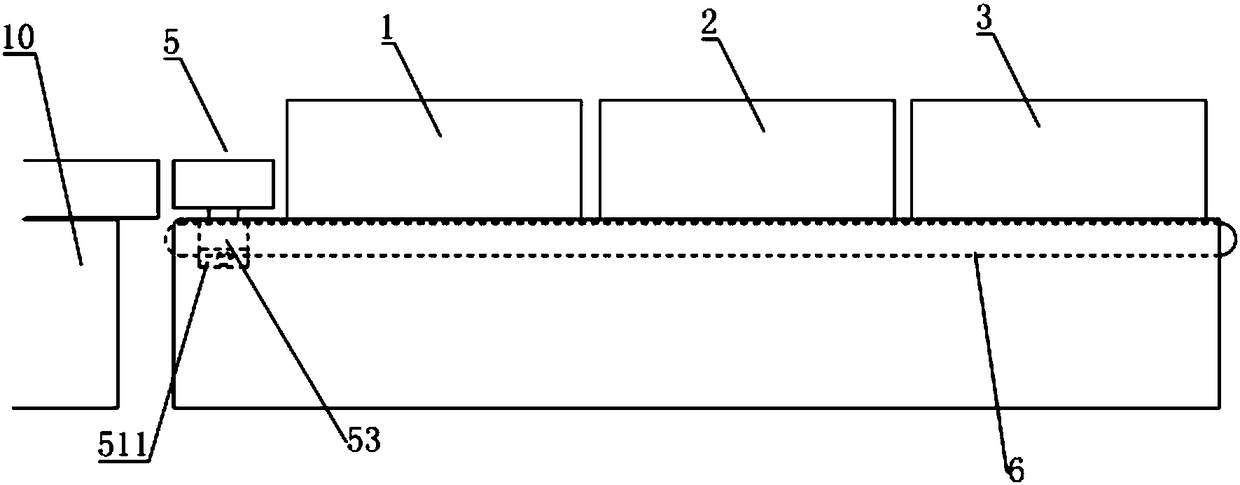

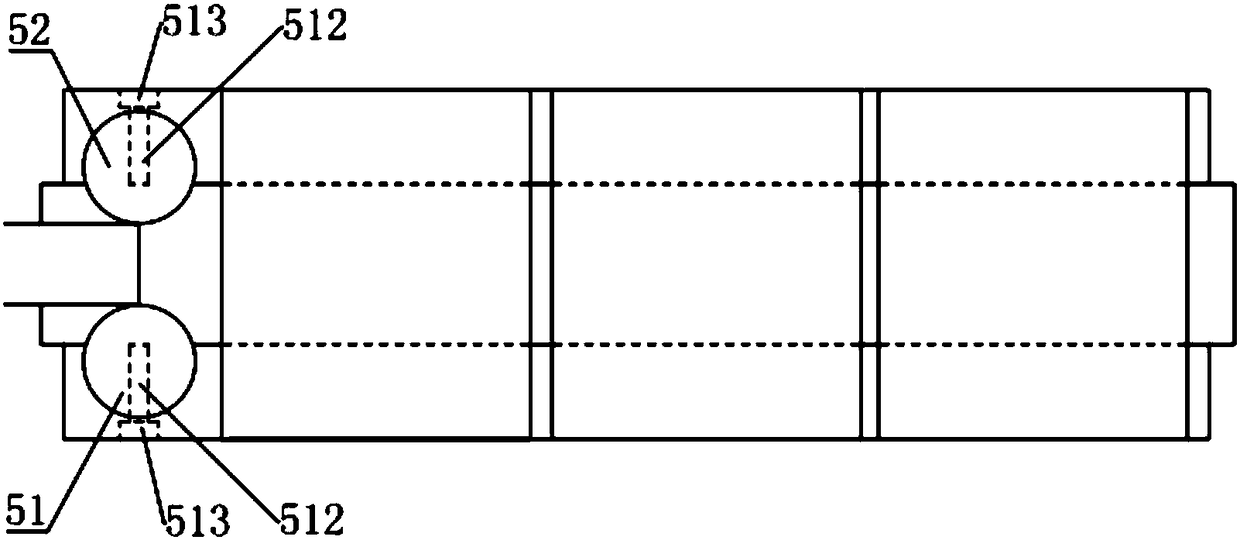

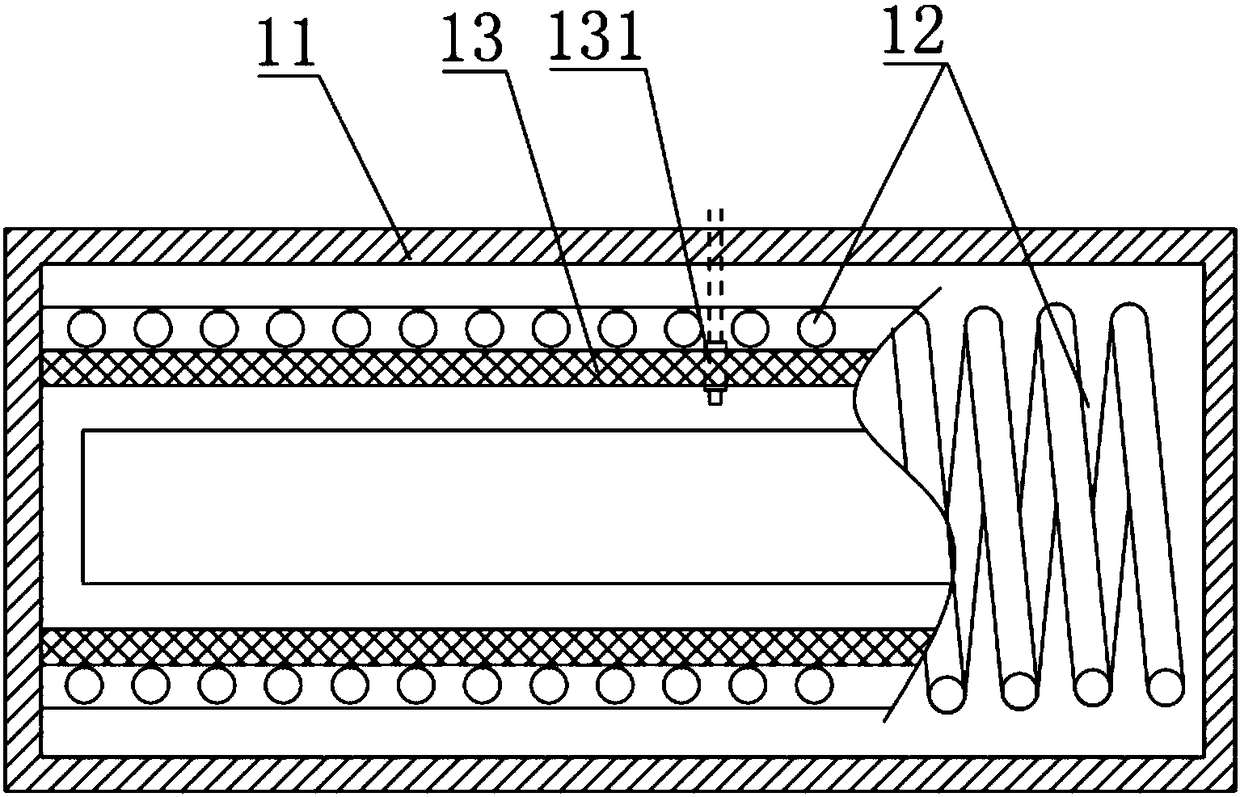

[0047] like figure 1 , 2 , 5 and 6 show the bearing ring production line with intermediate frequency induction heating furnace, including feeding unit 10, heating unit 20, forging unit 30, sorting unit 40, shot blasting unit 50, rolling unit 60, shaping Unit 70, cleaning unit 80 and blanking unit 90; wherein, the heating unit 20 is an intermediate frequency induction heating furnace, and the intermediate frequency induction heating furnace includes a preheating furnace 1, a heating furnace 2, a uniform temperature furnace 3, a guide rail 4, and an auxiliary feeding device 5 And the heating furnace base 6, the guide rail 4 passes through the preheating furnace 1, the heating furnace 2 and the uniform temperature furnace 3 arranged in sequence from front to back, the auxiliary feeding device 5 is arranged in front of the preheating furnace 1, the preheating furnace 1, The heating furnace 2 , the temperature-soaking furnace 3 , the guide rail 4 and the auxiliary feeding device 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com