Inward-curled-edge cylinder container

A cylinder and crimping technology, applied in packaging and other directions, can solve the problems of artificial sticking, unevenness and unsightly appearance, small base and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

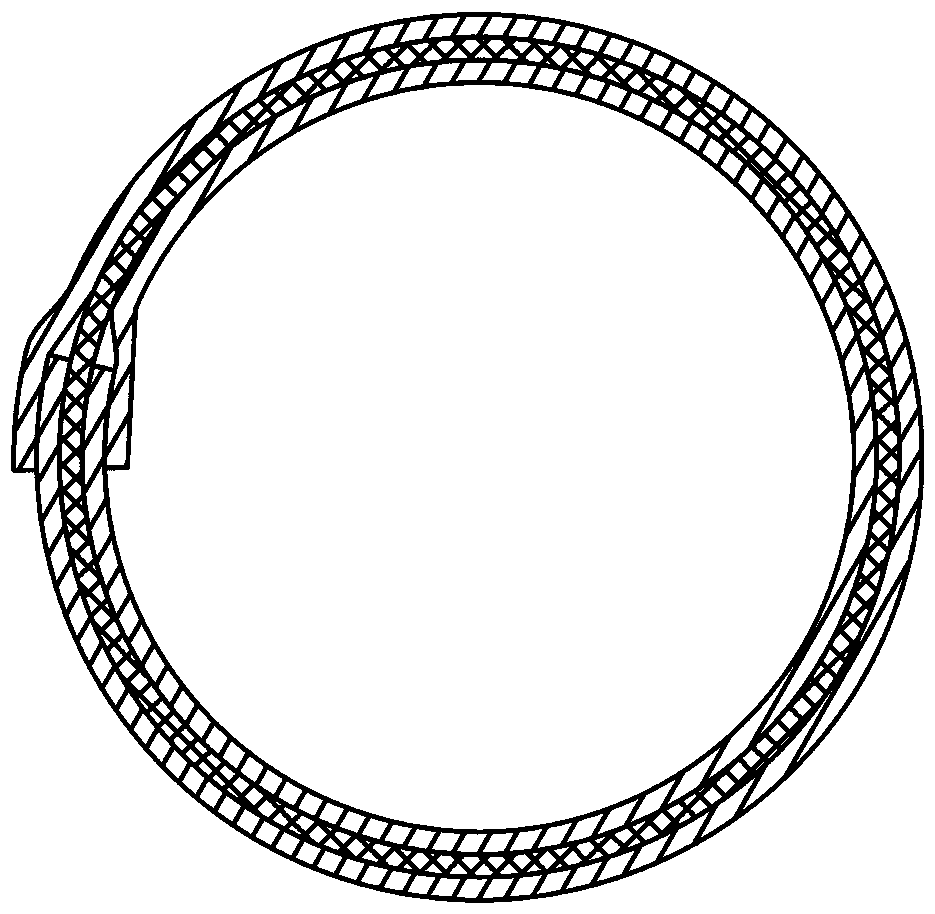

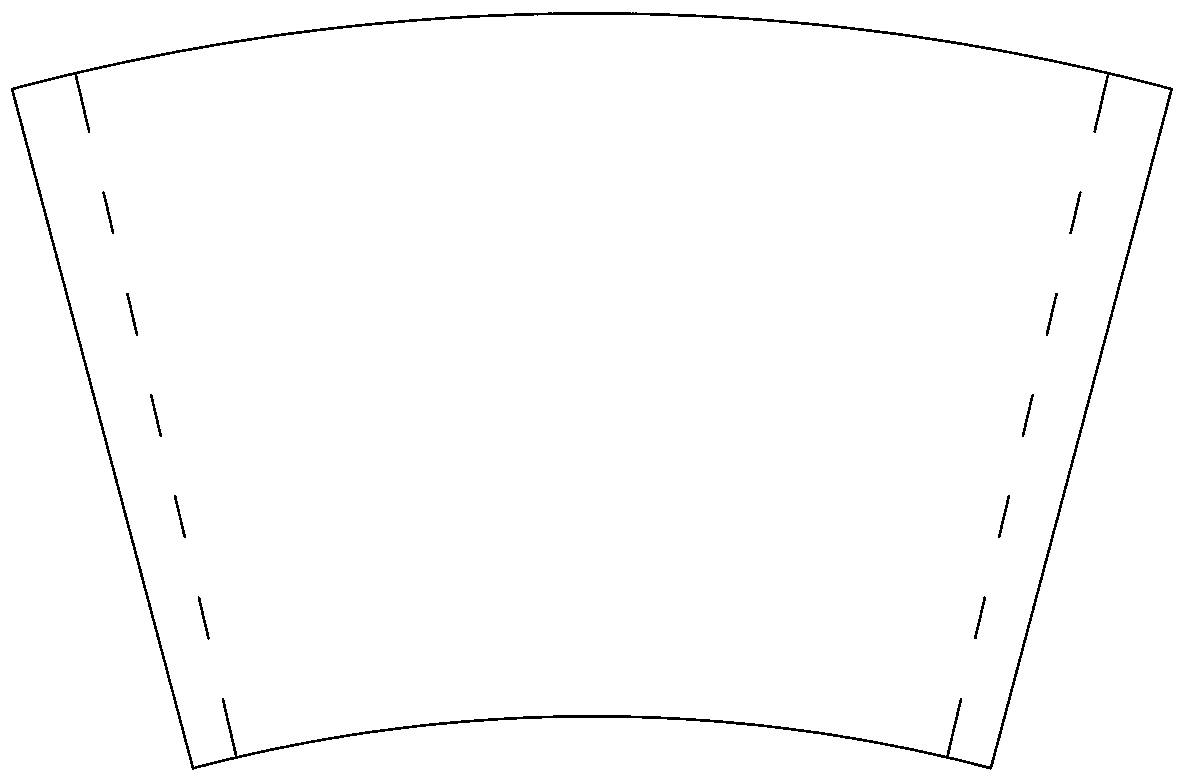

[0019] Such as Figure 4 , Figure 5 , Figure 6 As shown, the present invention provides a cylindrical container with inner crimping, including a cylindrical body 1 and a bottom sheet 2, the top of the body 1 is provided with an outlet 3, and the bottom sheet 2 is installed on the bottom of the body 1 The storage area 4 inside the body 1 is formed on the top, the outlet 3 is connected with the storage area 4, the cylindrical body 1 has a superimposed bonding seam 10 from top to bottom, and the bottom sheet 2 includes a horizontal sheet 5 and a vertically folded sheet 6 bent downward, the body 1 includes an outer sheet 7 and an inner flap 8 bent upward at the bottom of the body, and an inner hook of the body is formed between the outer sheet 7 and the inner flap 8 9. The vertical flap 6 is located between the outer sheet 7 and the inner flap 8 and enters the inner hook 9 of the body, so that the bottom sheet 2 is installed on the bottom of the body 1, and the top of the body...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap