Tanning device for production of leather

A technology for tanning and leather, which is applied to the field of tanning devices for leather production, can solve the problems of labor, reduced efficiency, increased workload, etc., and achieves the effects of easy disassembly and cleaning, improved efficiency, and stable structure

Inactive Publication Date: 2018-07-17

YANCHENG DEZHENG MACHINERY CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to solve the problem that the tanning of leather in the prior art is usually carried out by drums, but the output after tanning is usually manually fished, which increases the workload and reduces the efficiency, and proposes a Tanning plants for leather production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

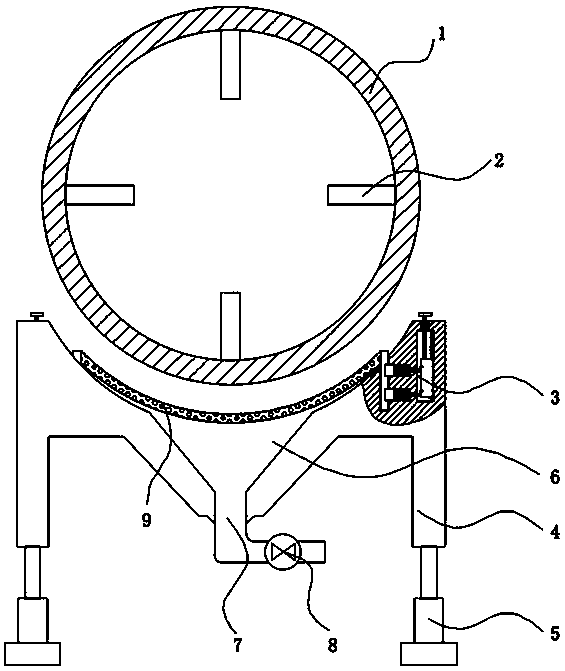

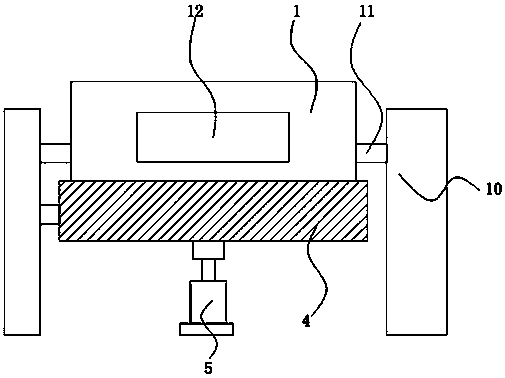

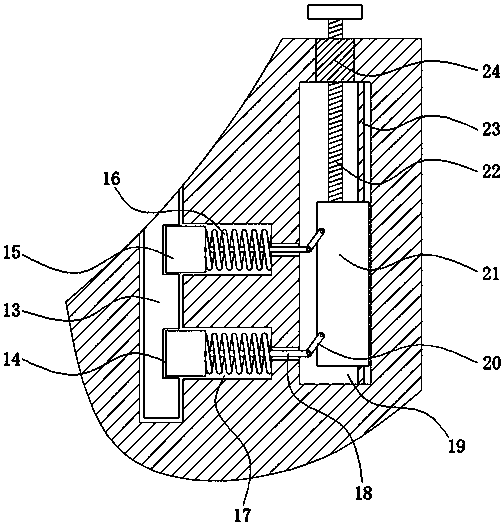

The invention discloses a tanning device for production of leather. The tanning device for production of leather comprises two symmetric cases, wherein a gear motor is mounted in one of the cases; a rotating shaft is mounted at an outputting end of the gear motor; the rotating shaft is connected with a drum which is arranged horizontally; a feeding opening is formed in the drum; a cover is mountedon the feeding opening; a collecting rack is arranged below the drum; the bottom ends of two sides of the collecting rack are connected with cylinders; a collecting groove is formed in the collectingrack; the bottom end of the collecting groove communicates with a discharging tube; a valve is mounted on the discharging tube; a screen is placed at the upper end of the collecting groove. The tanning device for production of leather is stable in structure, simple to operate and scientific and reasonable in design; after being tanned, the leather is collected through the collecting rack and thescreen, manual fishing is not required, liquid can be cleaned and recycled, the production efficiency is improved, the screen is convenient to disassemble and clean, and a large amount of time and effort of workers of a leather workshop can be saved.

Description

technical field [0001] The invention relates to the technical field of leather production devices, in particular to a tanning device for leather production. Background technique [0002] Tanning is a process in which tanning agent molecules penetrate into the skin and combine with active groups of raw hide collagen molecules to change their properties. Tanning makes the generation of cross-linking bonds between the collagen polypeptide chains of the skin, increases the stability of the collagen structure, improves the shrinkage temperature and the stability of moisture and heat resistance, and improves the ability to resist chemicals such as acids, alkalis, and enzymes. In the prior art, leather The tanning is usually carried out by drums, but the output after tanning is usually manually fished, which increases the workload and reduces the efficiency. Contents of the invention [0003] The purpose of the present invention is to solve the problem that the tanning of leathe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C14C15/00

CPCC14C15/00

Inventor 花金年

Owner YANCHENG DEZHENG MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com