Rapidly assembled lamp

A lighting and fast technology, which is applied to the parts of lighting devices, lighting devices, fixed lighting devices, etc., can solve the problems of inability to guarantee the personal safety of assemblers, low assembly efficiency, and electric shock of assemblers, so as to eliminate hidden dangers of electric shock and increase Stability, the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides an end cover of a lamp.

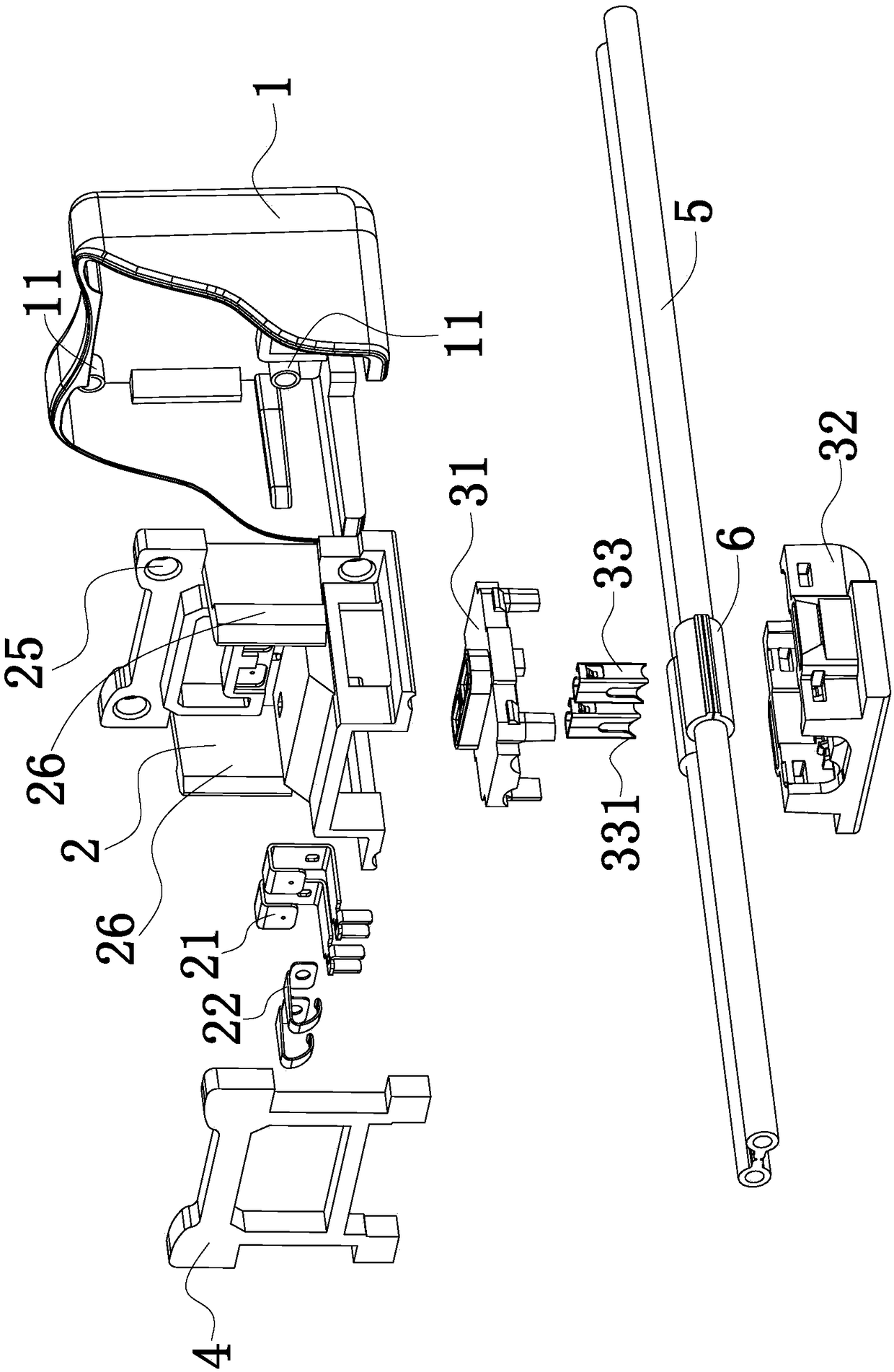

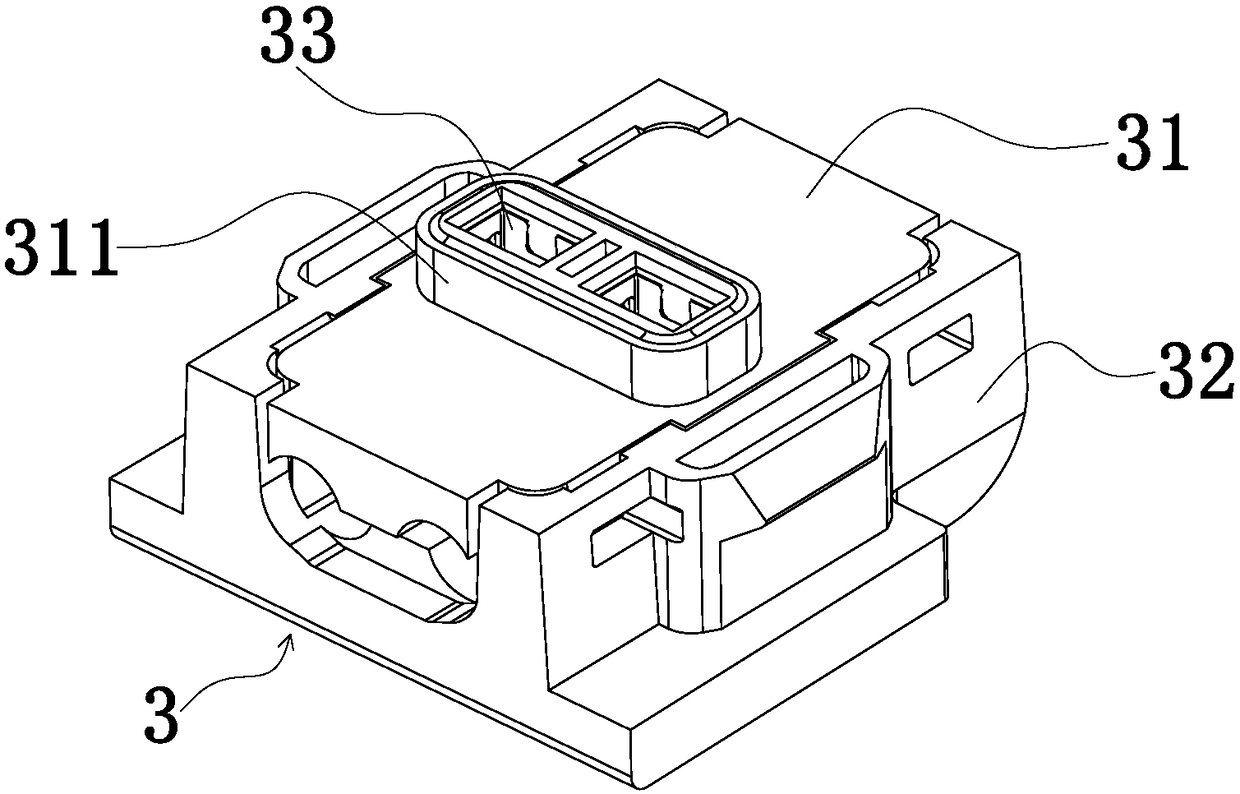

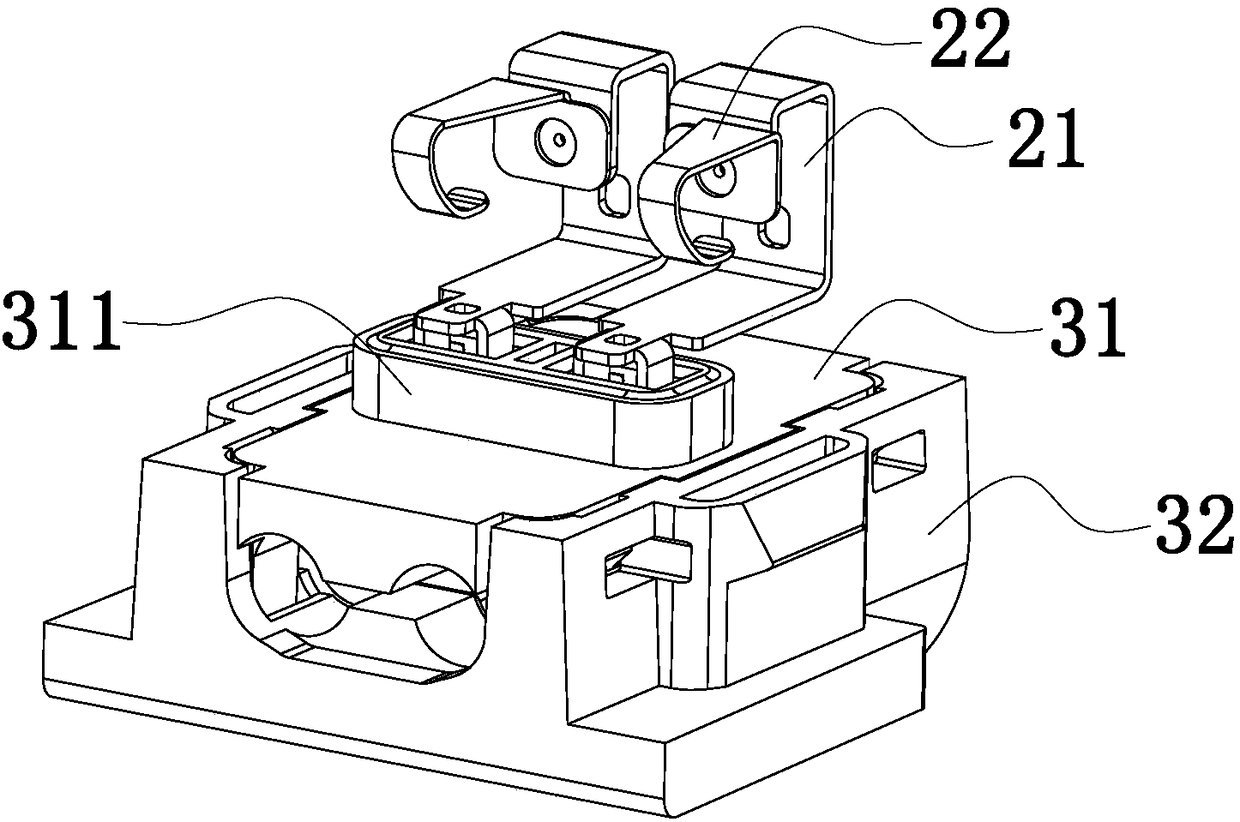

[0040] Such as Figure 1 to Figure 5 As shown, a lamp end cover includes an end cover body 1, a connecting seat 2 and a power-taking base 3, the power-taking base 3 includes an upper cover 31 and a base 32, the upper cover 31 is provided with four buckles around the base 32 Corresponding positions are provided with four slots, and the buckles cooperate with the slots so that the upper cover 31 is snapped onto the base 32 . The two parts are connected by clamping, and can be installed in one step, which saves assembly steps and improves assembly efficiency. The upper cover 31 and the base 32 are all provided with semicircular grooves, the upper cover 31 and the base 32 are snapped together, and the grooves of the two form passages (not marked in the figure) for external electric wires to pass through. Not marked in ) pass through the power-taking seat 3 by this passage.

[0041] The power-taking base 3 is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com