An electrical automation industrial dust removal device

A technology of electrical automation and dust removal device, which is applied in combination devices, chemical instruments and methods, separation methods, etc., can solve the problems of high energy consumption, high cost of small and medium-sized enterprises, complex structure of dust collection devices in workshops, etc., to improve dust collection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

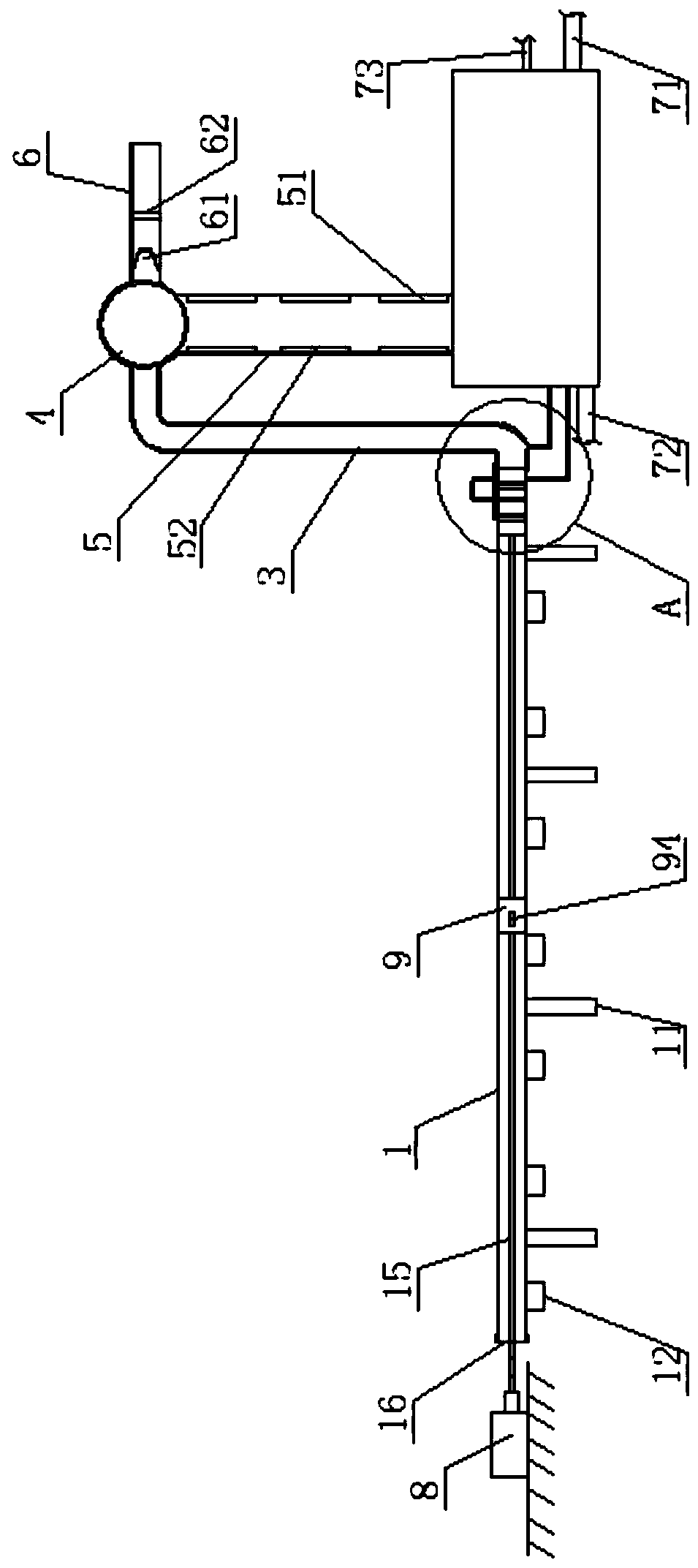

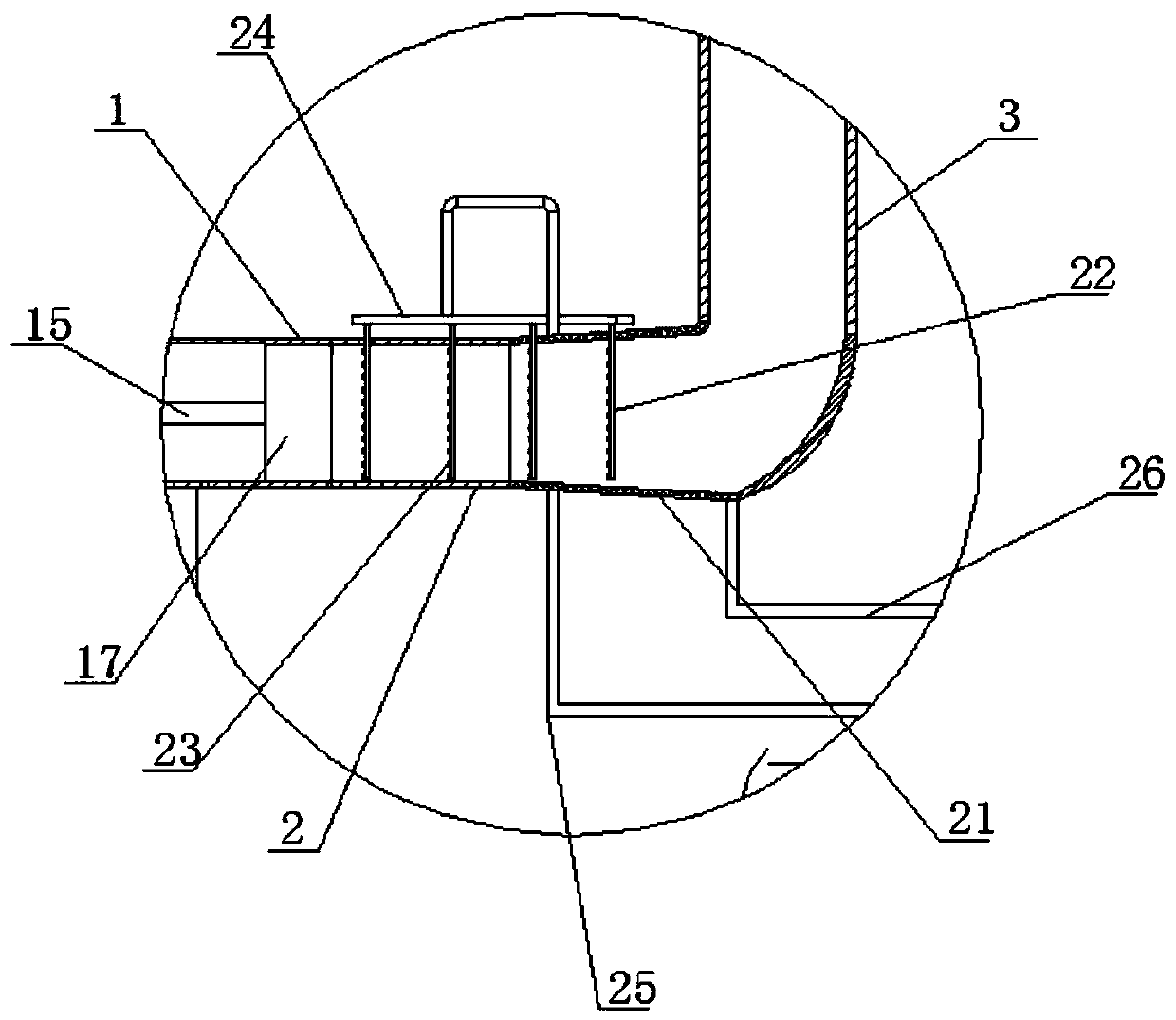

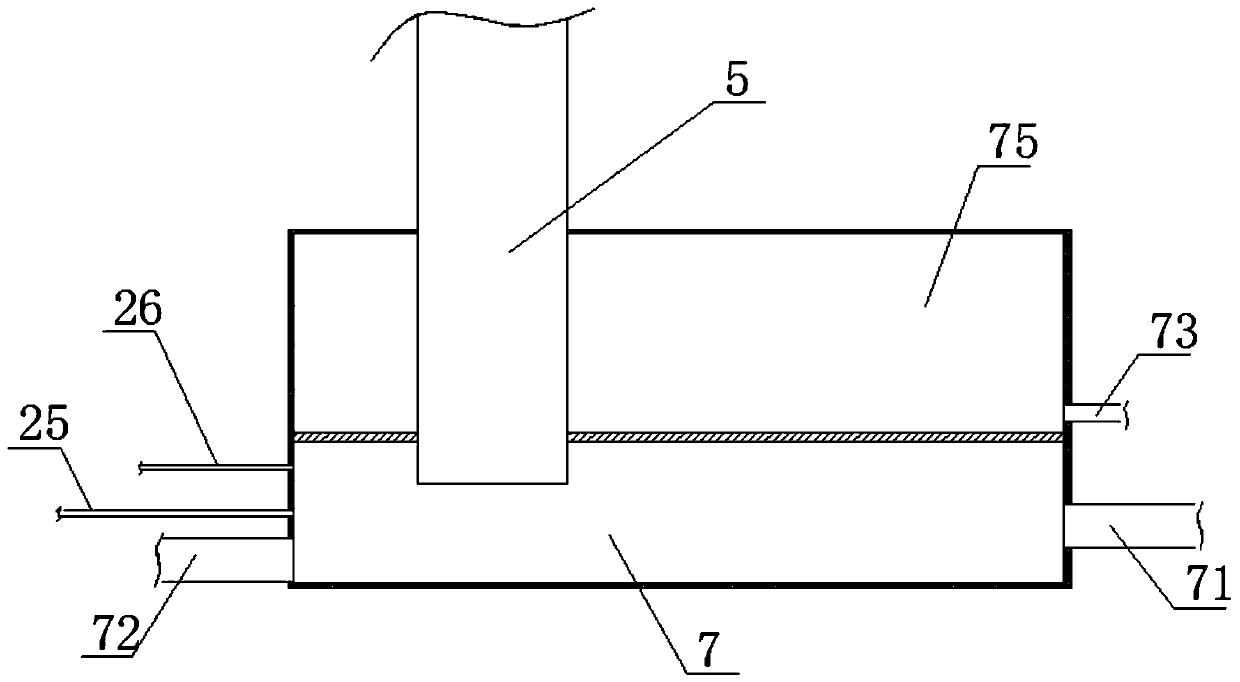

[0034] An electrical automation industrial dust removal device, including a dust suction device and a dust collection device, the dust collection device includes a dust collection box, and the dust collection box is divided into a sedimentation chamber 7 containing liquid, and the precipitation chamber 7 is equipped with a Dismounted see-through glass, the top of the settling chamber 7 is provided with a filter screen; the liquid in the settling chamber 7 can be water or water with adsorbent or be filled with weakly alkaline or weakly acidic liquid according to the working environment of the workshop, so Liquid outlet pipe 25, liquid inlet pipe 26, liquid replenishment pipe 71 and liquid discharge pipe 72 are set on the side wall of the precipitation chamber 7, and the liquid in the precipitation chamber 7 is replenished or drained through the liquid replenishment pipe 71 and liquid discharge pipe 72. A water pump is arranged on the liquid outlet pipe 25, a water distribution p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com