Low temperature environment test chamber and low temperature environment test method

A low-temperature environment and test chamber technology, which is applied in the field of low-temperature environment test chambers, can solve the problems that it is difficult to ensure a rapid response to the experimental temperature and the rapid response to the ambient temperature is difficult to achieve, and achieve the effect of rapid temperature response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solution of the present invention will be described in detail below in conjunction with the drawings and specific embodiments, but it is not intended to limit the present invention.

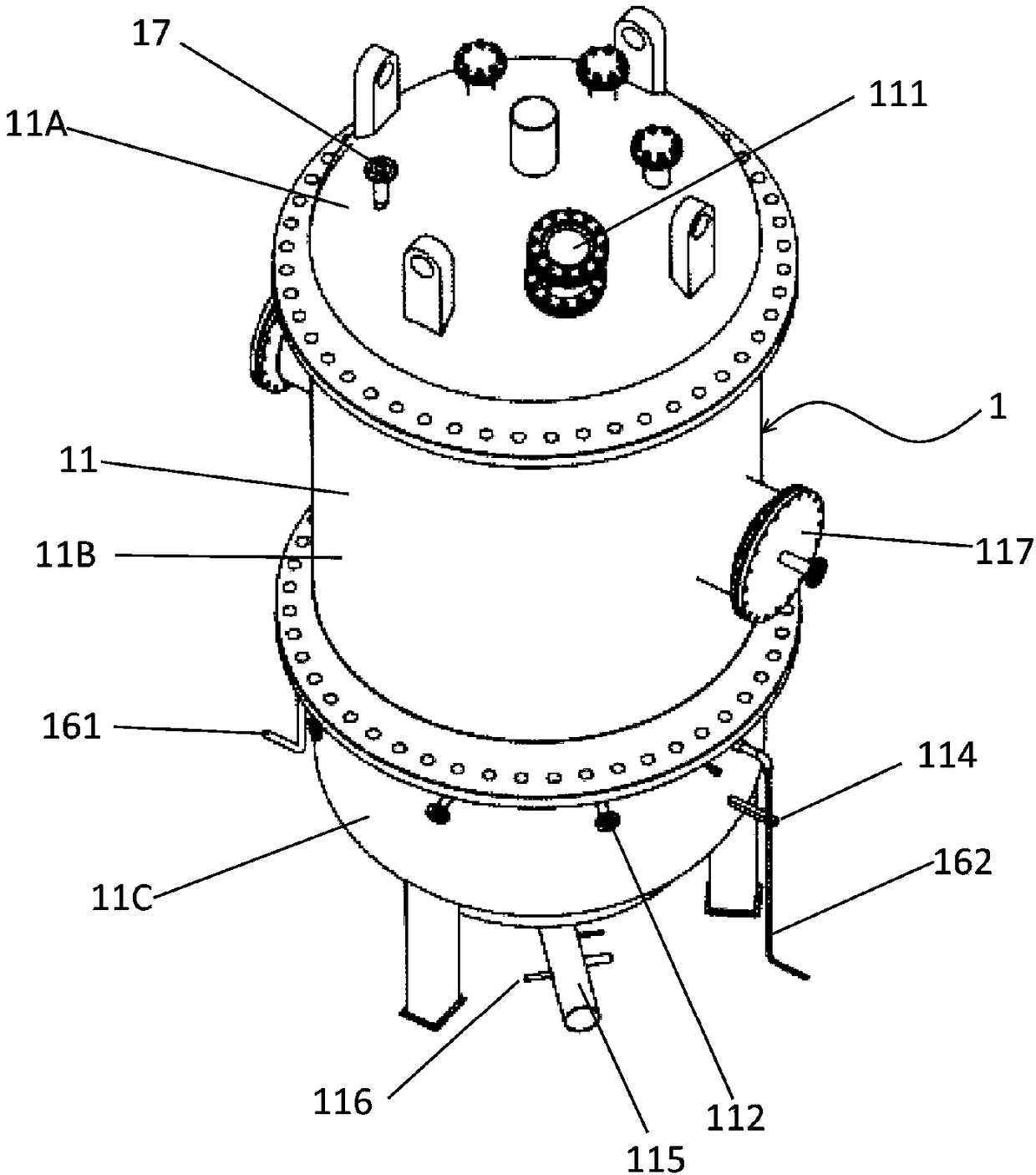

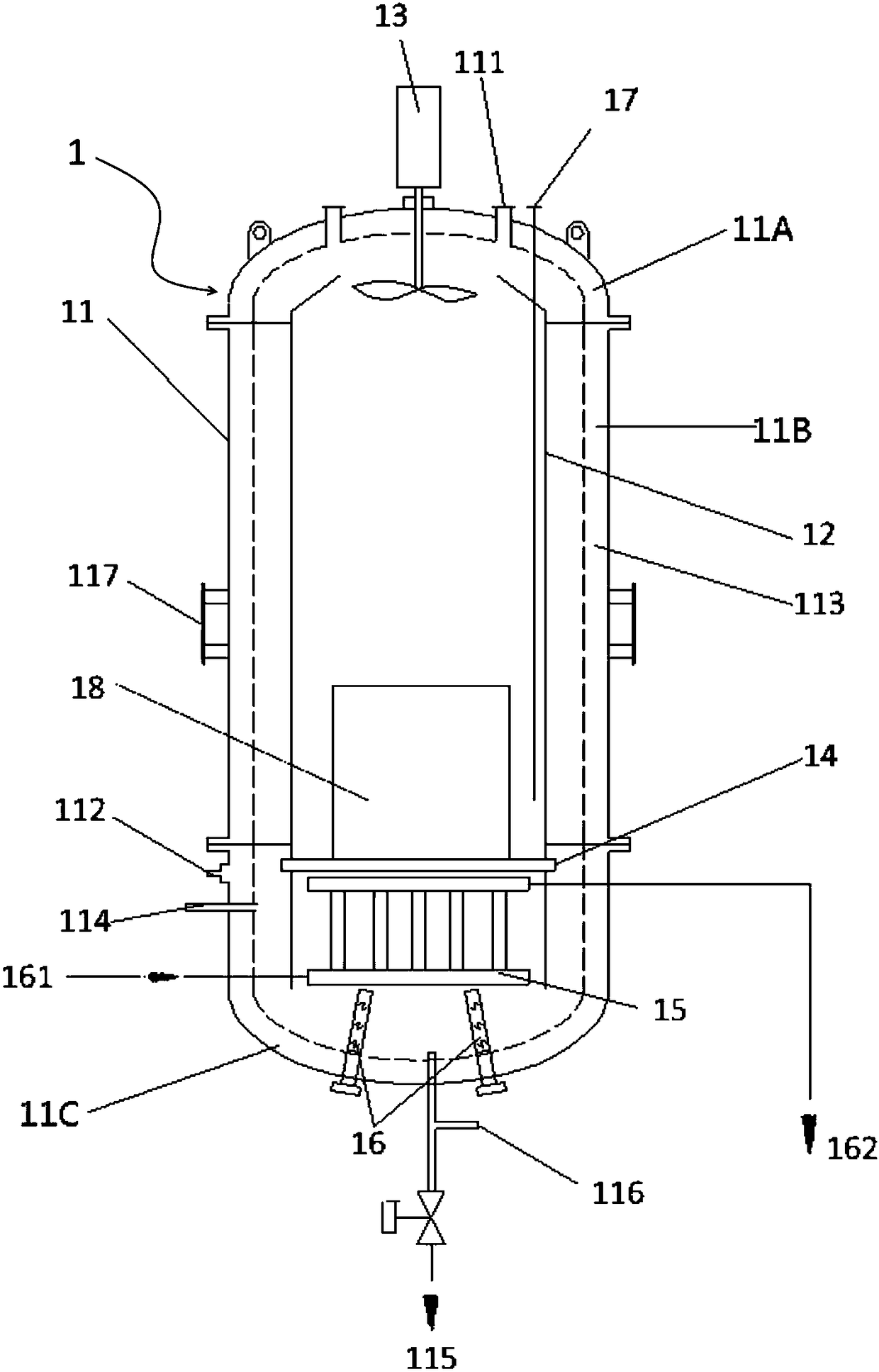

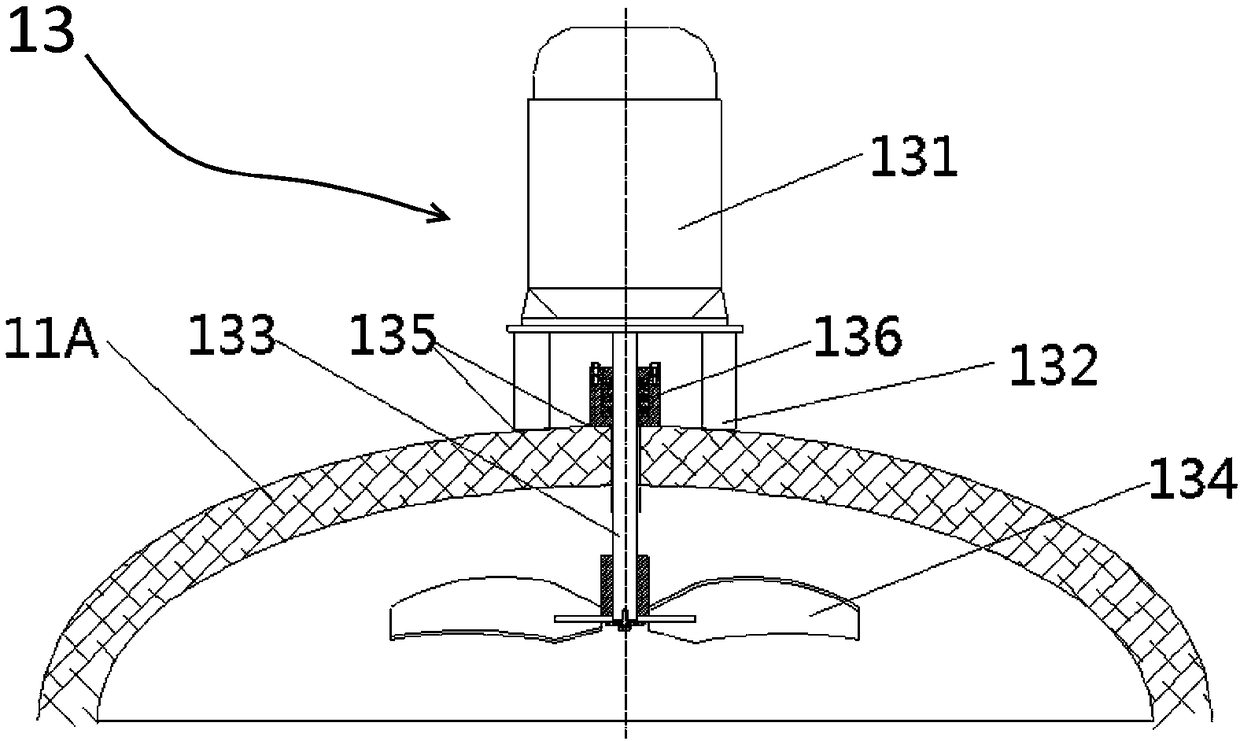

[0066] Please also see figure 1 with figure 2 , figure 1 It is a perspective view of a low temperature environment test chamber according to an embodiment of the present invention, figure 2 It is a structural schematic diagram of a low-temperature environment test chamber according to an embodiment of the present invention. Such as figure 2 As shown, the low temperature environment test chamber 1 has a shell 11, which provides a reliable test space for the low temperature environment and withstands internal pressure. The shell 11 includes an upper head 11A, a straight section 11B and a lower head 11C from top to bottom. The head 11A, the lower head 11C and the straight section 11B are connected by flanges; the inner air duct 12 is sleeved in the housing 11, and the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com