Electric eccentric screwdriver

A screwdriver, screwdriver head technology, applied in screwdrivers, power tools, wrenches, etc., can solve problems such as loss, delay in work process, and discount on work efficiency, and achieve the effect of reasonable structure design, reduction of labor intensity, and improvement of efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

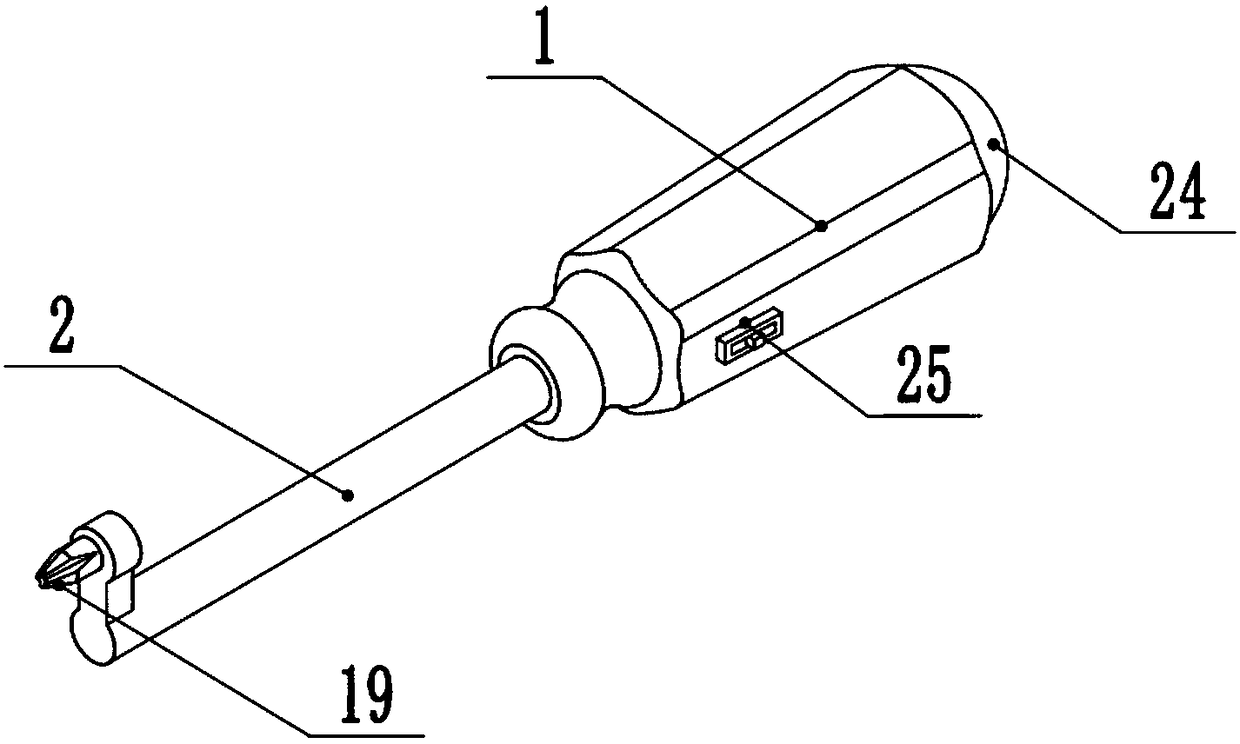

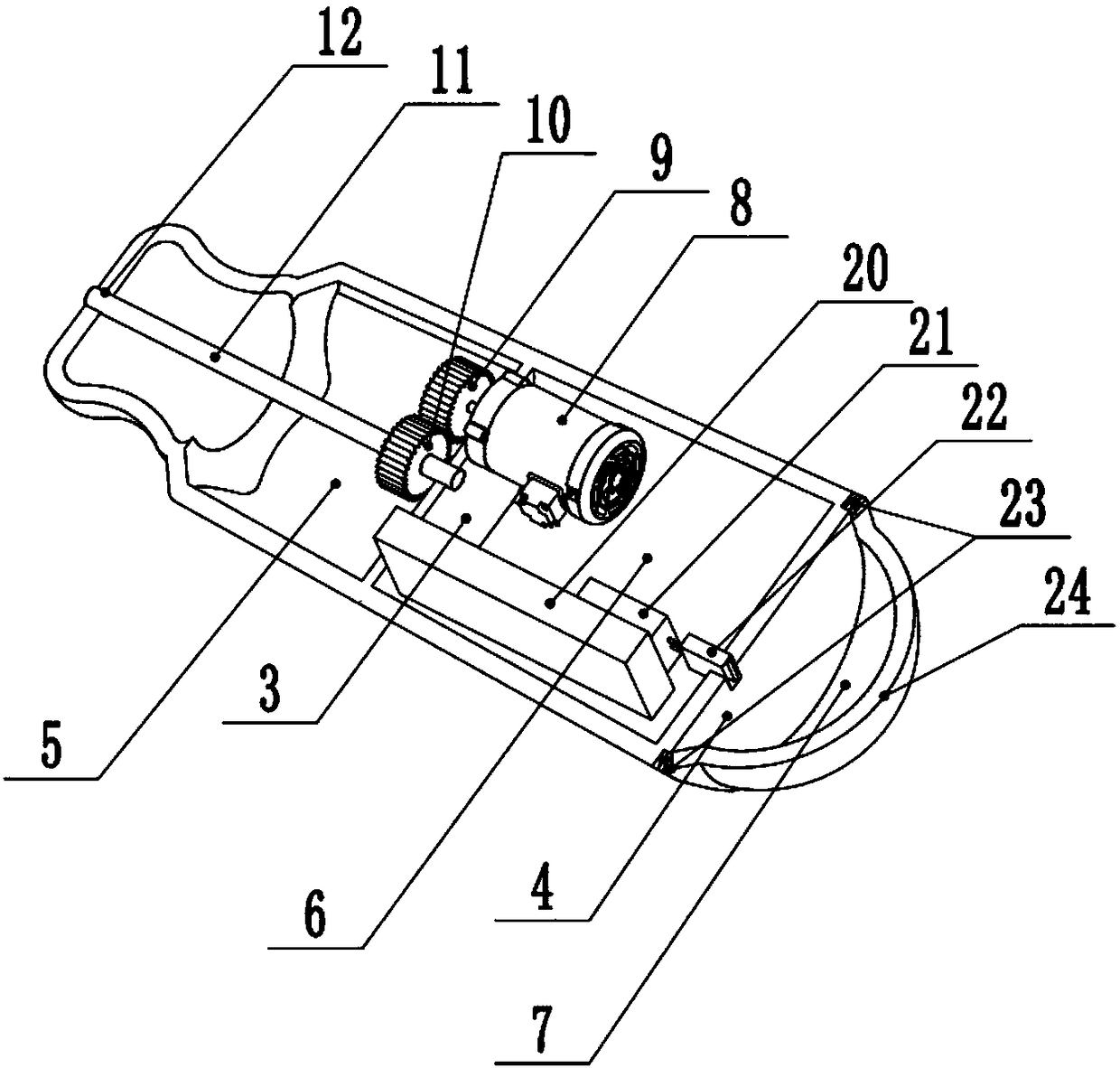

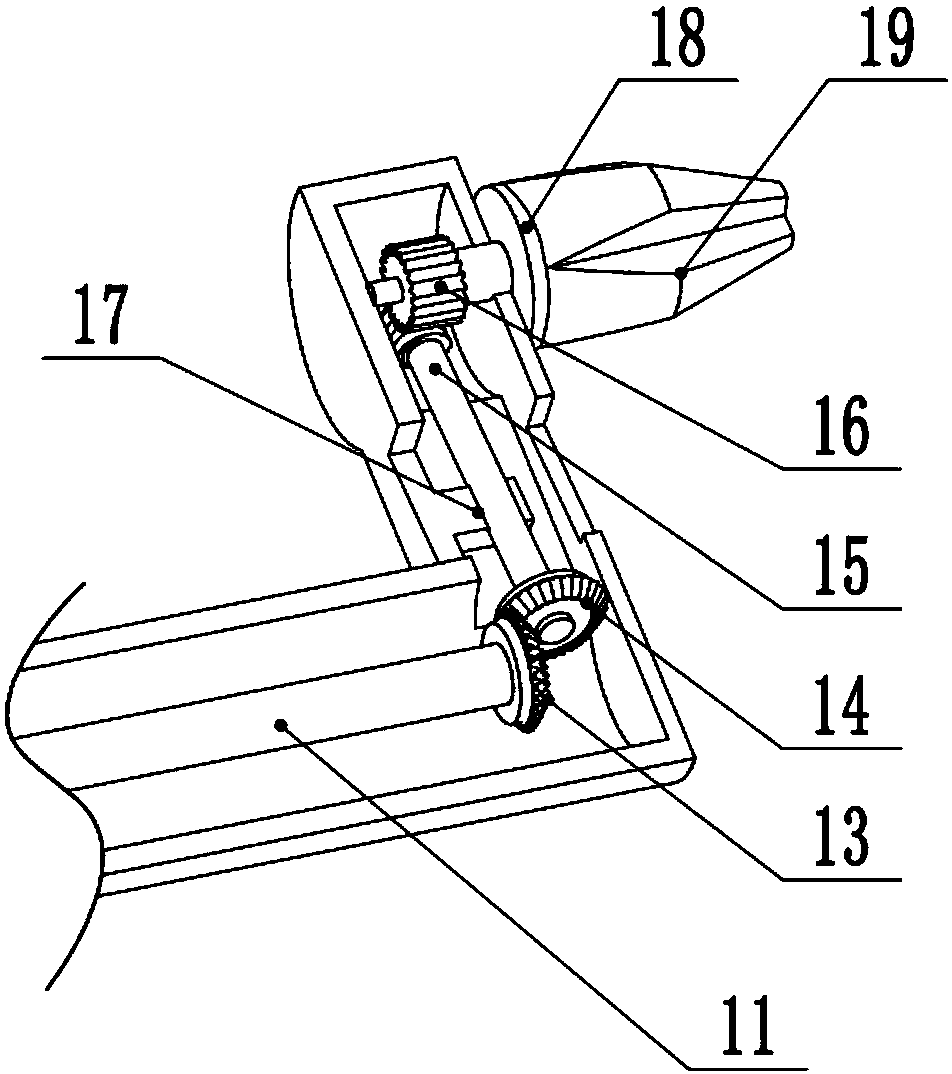

[0022] Such as figure 1 As shown in , an electric eccentric screwdriver is characterized in that it includes a hollow screwdriver handle 1, the front end of the screwdriver handle 1 is coaxially connected with a hollow L-shaped screwdriver shaft 2, and the inside of the screwdriver handle 1 is provided with a front stop Plate 3 and rear baffle 4 two-layer baffles divide the cavity of the whole screwdriver handle 1 into three parts, front cavity 5, hollow cavity 6 and rear cavity 7, and a power control part is installed in the hollow cavity. The power control part includes a motor 8, and the motor 8 is installed on the front baffle 3, and the rotating shaft of the motor 8 passes through the front baffle 3 and is coaxially installed on the shaft hole provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com