Separation Mechanism for Hypersonic Inlet Shield

A separation mechanism and hypersonic technology, which is applied in the direction of gas turbine devices, turbine/propulsion device air intakes, mechanical equipment, etc., can solve the problem that the explosion bolt separation mechanism cannot be scaled down, and achieve simple and compact structure and high tensile strength , the effect of high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

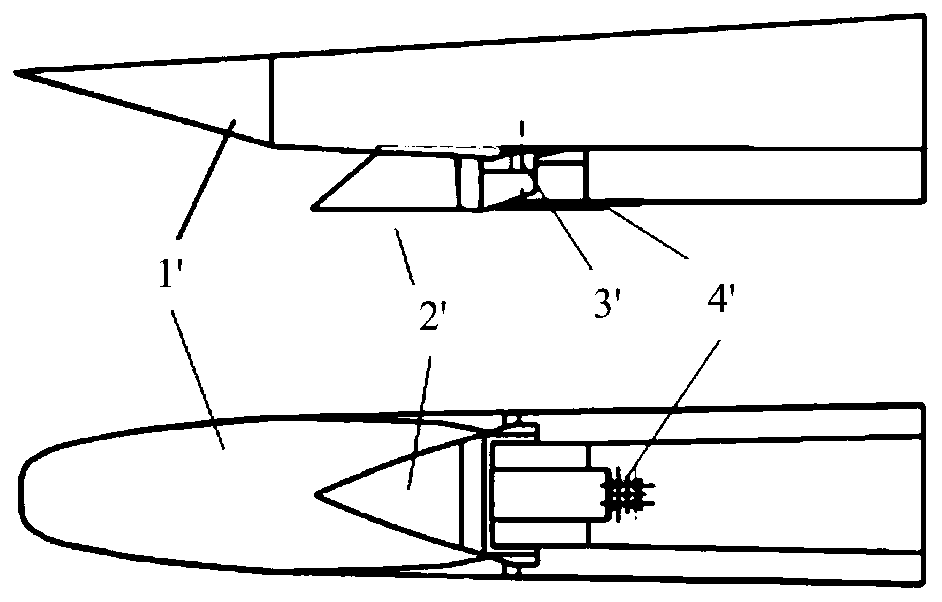

[0029] The object of this embodiment is the dynamic separation test model of the hypersonic inlet protective cover, see figure 1 , figure 1 A schematic diagram of a hypersonic aircraft precursor with an air inlet protective cover in the prior art is shown, in which 1' is the aircraft precursor, 2' is the air inlet protective cover, 3' is the installation position of the explosive bolt, and 4' is the bending Fragment.

[0030] The separation process of the air inlet protection cover 2' is as follows: the explosion bolt is required to give an unlocking instruction, and when the explosion bolt unlocking instruction is given, the explosion bolt fracture protection cover wraps around the bending fragment 4' under the constraint of the bending fragment 4' The weakening groove rotates, and when a certain angle is reached, the bending fragment 4' breaks, and the air inlet protective cover 2' is completely unlocked and starts to move freely.

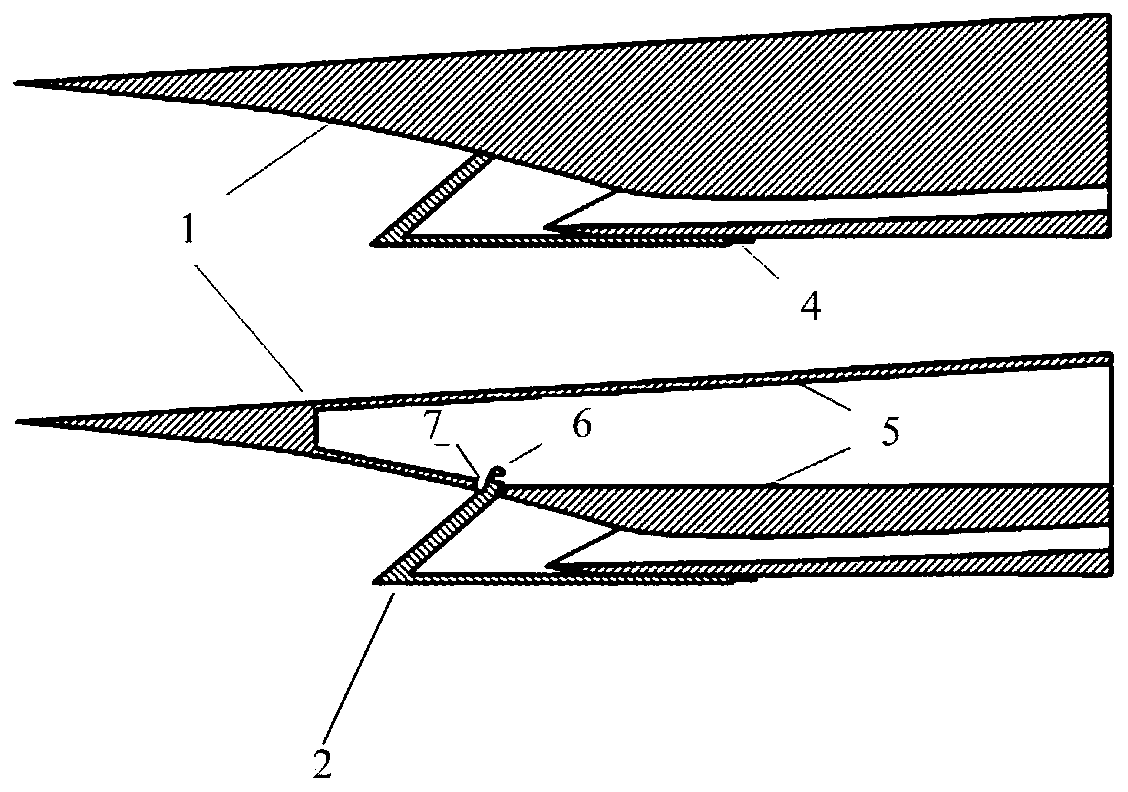

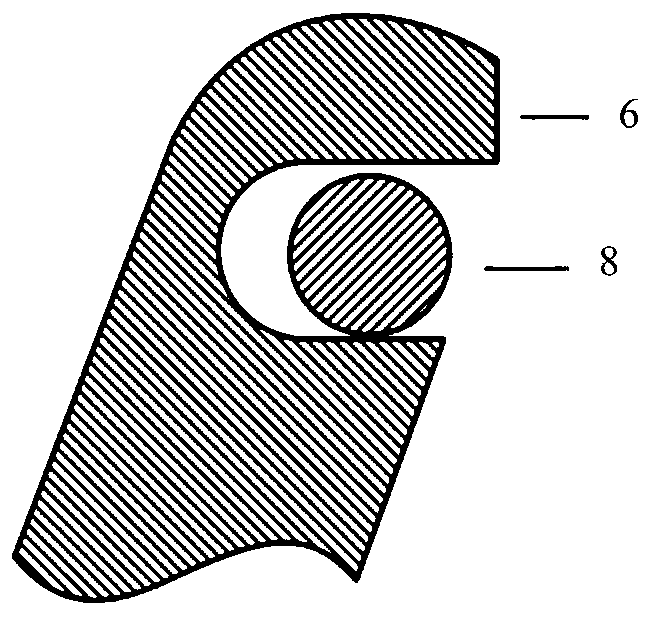

[0031] see figure 2 , this embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com