Vernier caliper and use method thereof

A vernier caliper and vernier technology, applied in the field of vernier calipers, can solve the problems of increasing the matching gap between the main ruler and the vernier, affecting the measurement accuracy, and deteriorating sliding properties, and achieve the effects of enhanced rigidity, flexible structural design, and improved measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below.

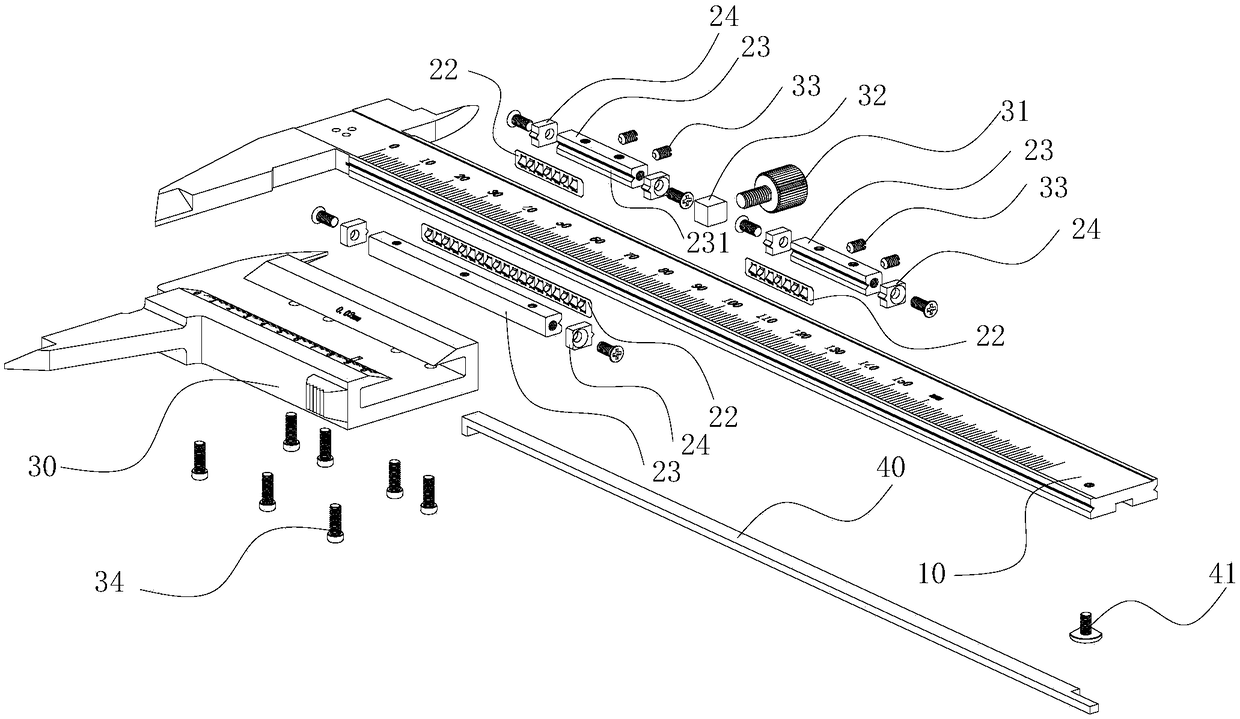

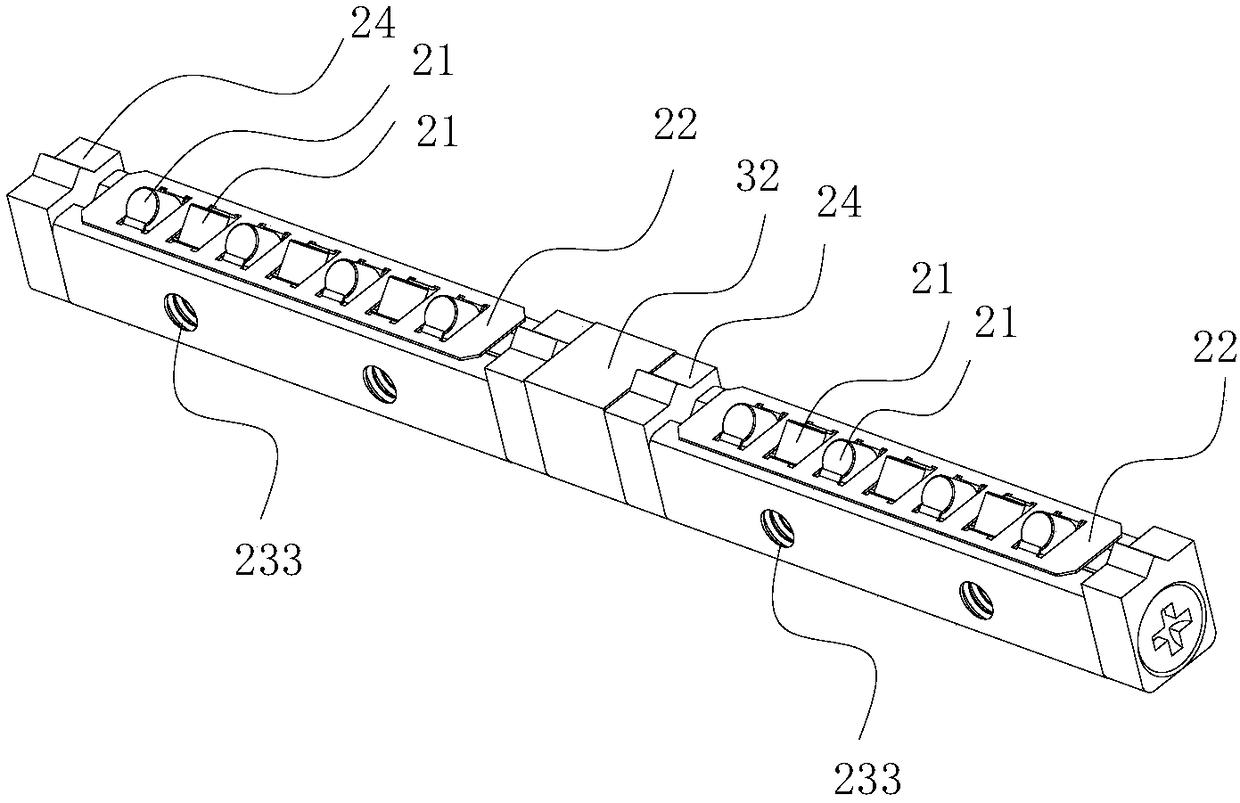

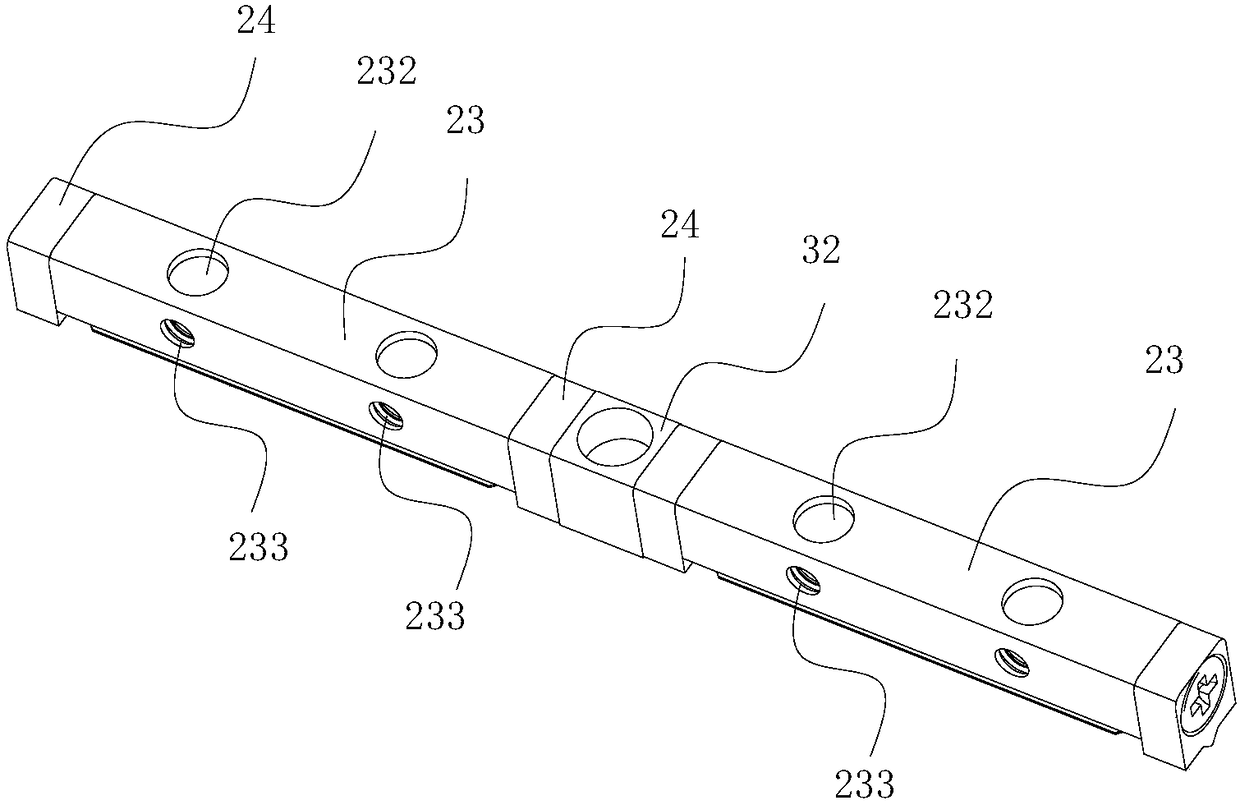

[0041] like figure 1 As shown, the vernier caliper includes a main ruler 10, a vernier 30, a sliding assembly and a positioning column 31, the sliding assembly is located between the vernier 30 and the main ruler 10, the vernier 30 is slidingly socketed with the main ruler 10, and the two sides of the main ruler 10 Both are provided with ruler body guide rails, and the ruler body guide rails cooperate with the sliding assembly. A positioning post 31 is arranged between the vernier 30 and the main ruler 10, and the positioning post 31 protrudes from the side of the vernier 30.

[0042] A sliding assembly is arranged on the blade body guide rail on the side not having the positioning post 31, two sliding assemblies are arranged on the blade body guide rail on the side having the positioning post 31, and a copper pressure block 32 is arranged between the two sliding assemblies, and The copper pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com