Apparatus and method for testing wear resistant performance of material

An anti-wear performance, test piece technology, applied in the direction of testing wear resistance, measuring devices, analyzing materials, etc., can solve the problems of waste, the flow rate and pressure of the nozzle cannot be measured, and the accurate flow rate of the nozzle cannot be measured, etc., to achieve control. Accurate, accurate test results, high flow controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

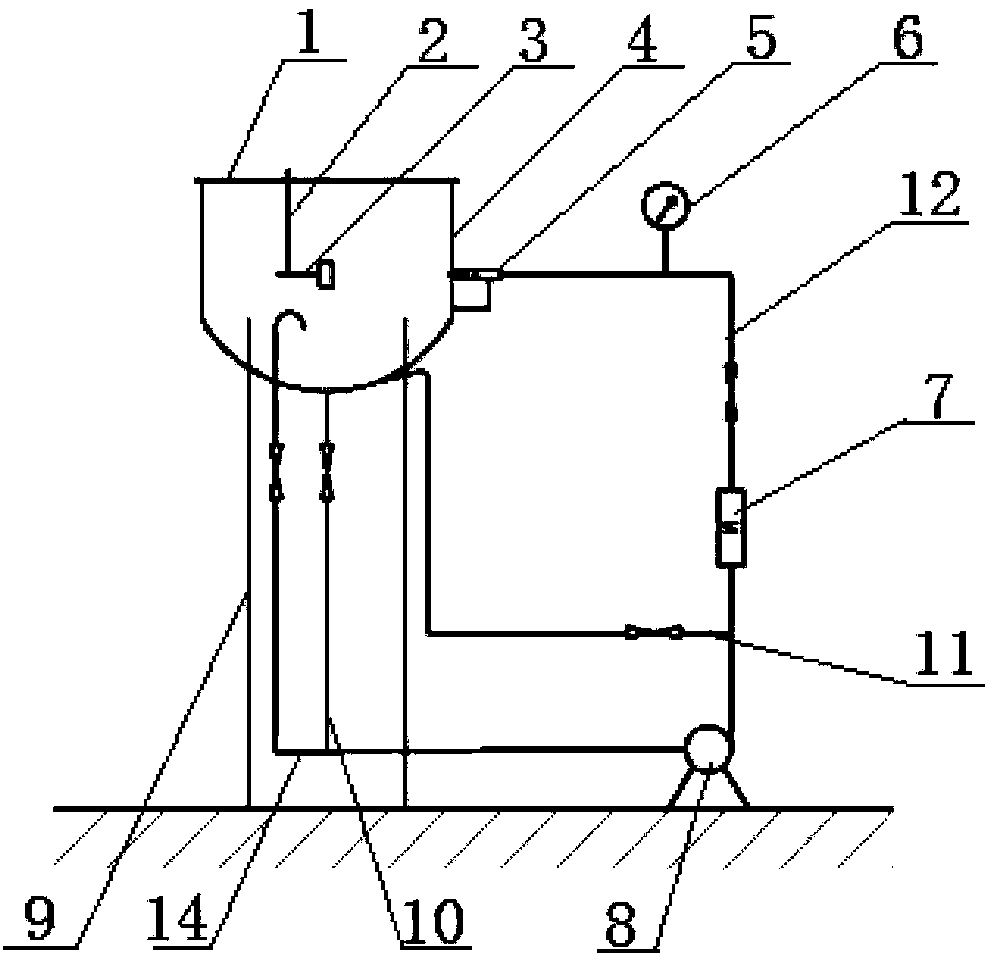

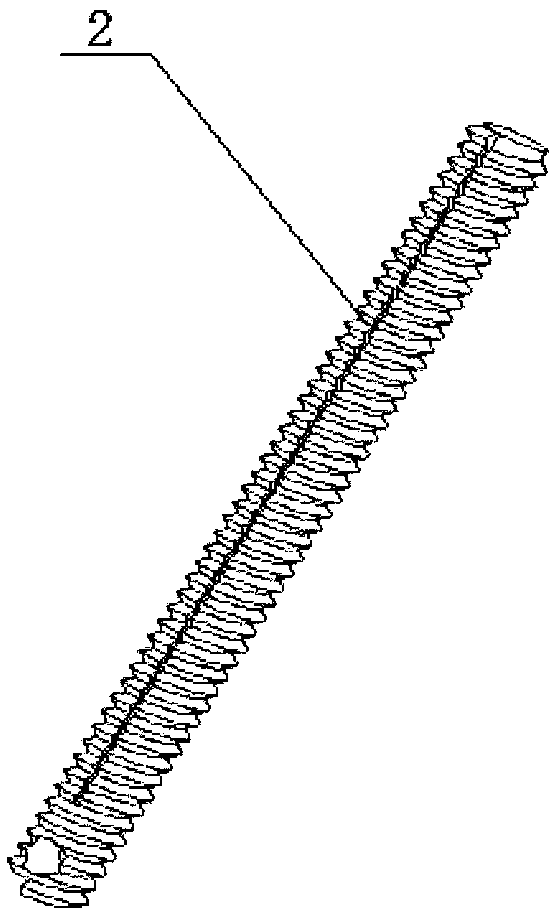

[0039] Such as figure 1 As shown, a device for testing the wear resistance of materials according to the present invention includes a cover plate 1, a vertical support for the test piece 2, a horizontal support for the test piece 3, a water tank 4, a nozzle 5, a pressure gauge 6, and a flow meter 7 , circulation pump 8, pipeline and integral support 9;

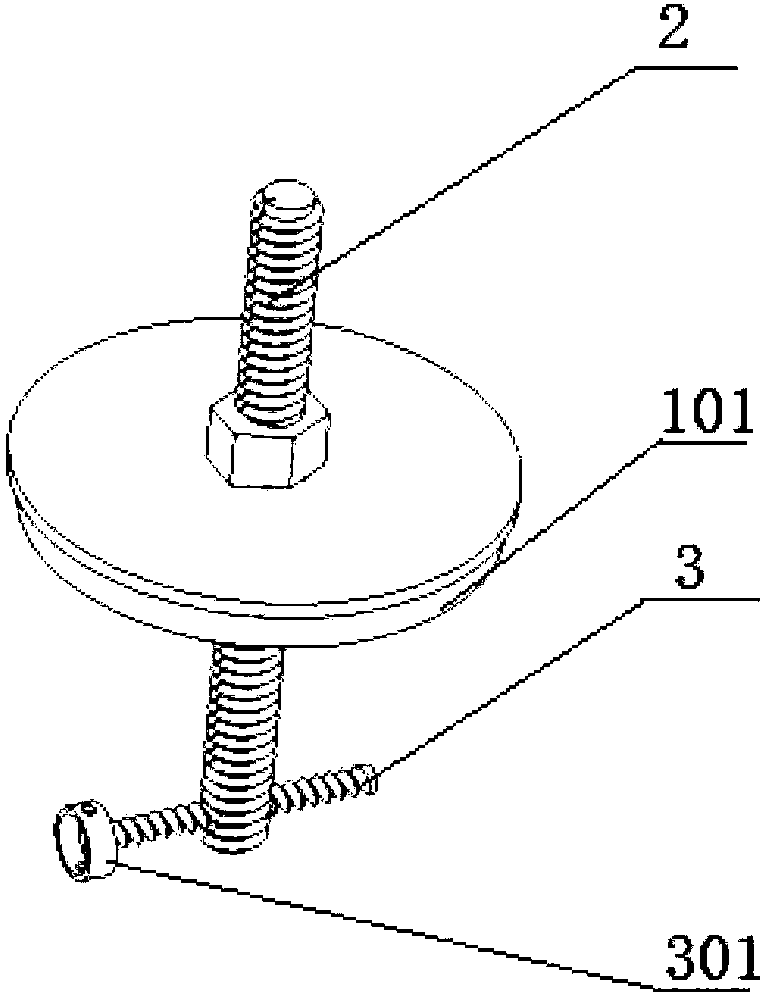

[0040] The upper part of water tank 4 is a hollow cylinder, and the lower part is a hollow hemispherical shape. Sandy water is housed in the water tank 4. The top opening of the water tank 4 is as figure 2 As shown, the cover plate 1 is a circular plate, the lower surface of the cover plate 1 is provided with a second columnar ring 101, the second columnar ring 101 is coaxial with the cover plate 1, and its outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com