Multi-chamber serial connection gas sample cell with built-in reflecting mirror

A gas sample cell and sample cell technology, applied in the field of multi-chamber gas sample cells in series, can solve the problems of difficult adjustment of the optical path of the instrument, increase the workload of instrument operation and maintenance, increase the workload of calibration instruments and the cost of operation and maintenance, etc., to achieve Effects of reducing analysis errors and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

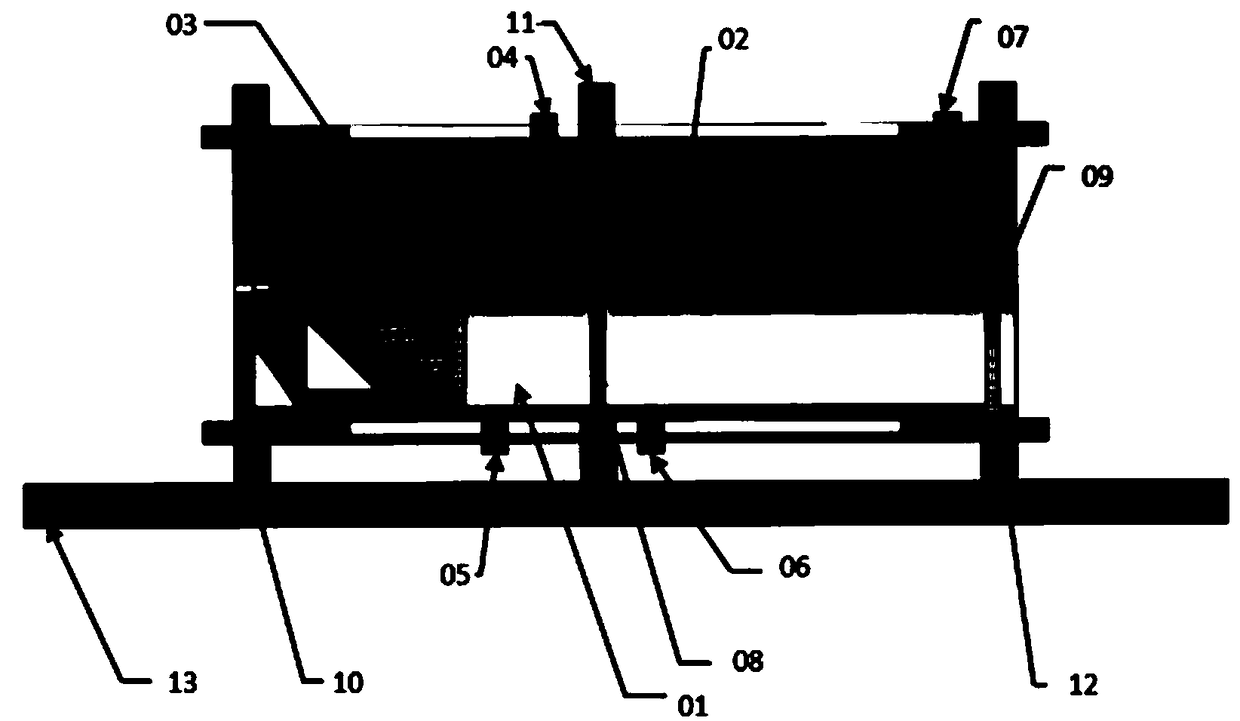

[0018] refer to figure 1 The bitbook uses a multi-chamber series gas sample cell device with a built-in reflector, including: the first sample cell 01, the second sample cell 02, the quartz mirror 03, the first air inlet 04, the first air outlet 05, the second Two air inlet holes 06, the second air outlet hole 07, the middle quartz window 08, the front quartz window 09, the rear flange 10, the middle connecting flange 11, and the front window flange 12.

[0019] The length of the second sample cell 02 is 9 cm.

[0020] The air outlet 05 of the first sample cell 01 and the air inlet 06 of the second sample cell 02 are connected by a hose, so that the first sample cell and the second sample cell can be used in series.

[0021] The inner and outer diameters of the first sample pool 01 and the second sample pool 02 are the same. The distance between the quartz mirror 03 in the first sample cell and the middle quartz window 08 is 3 cm.

[0022] The outer diameter of the middle q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com