Cupping tank with negative pressure compensation cavity

一种补偿腔、火罐的技术,应用在医疗器械领域,能够解决不能够取得最佳治疗效果、体表撕扯感和疼感、撒气等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

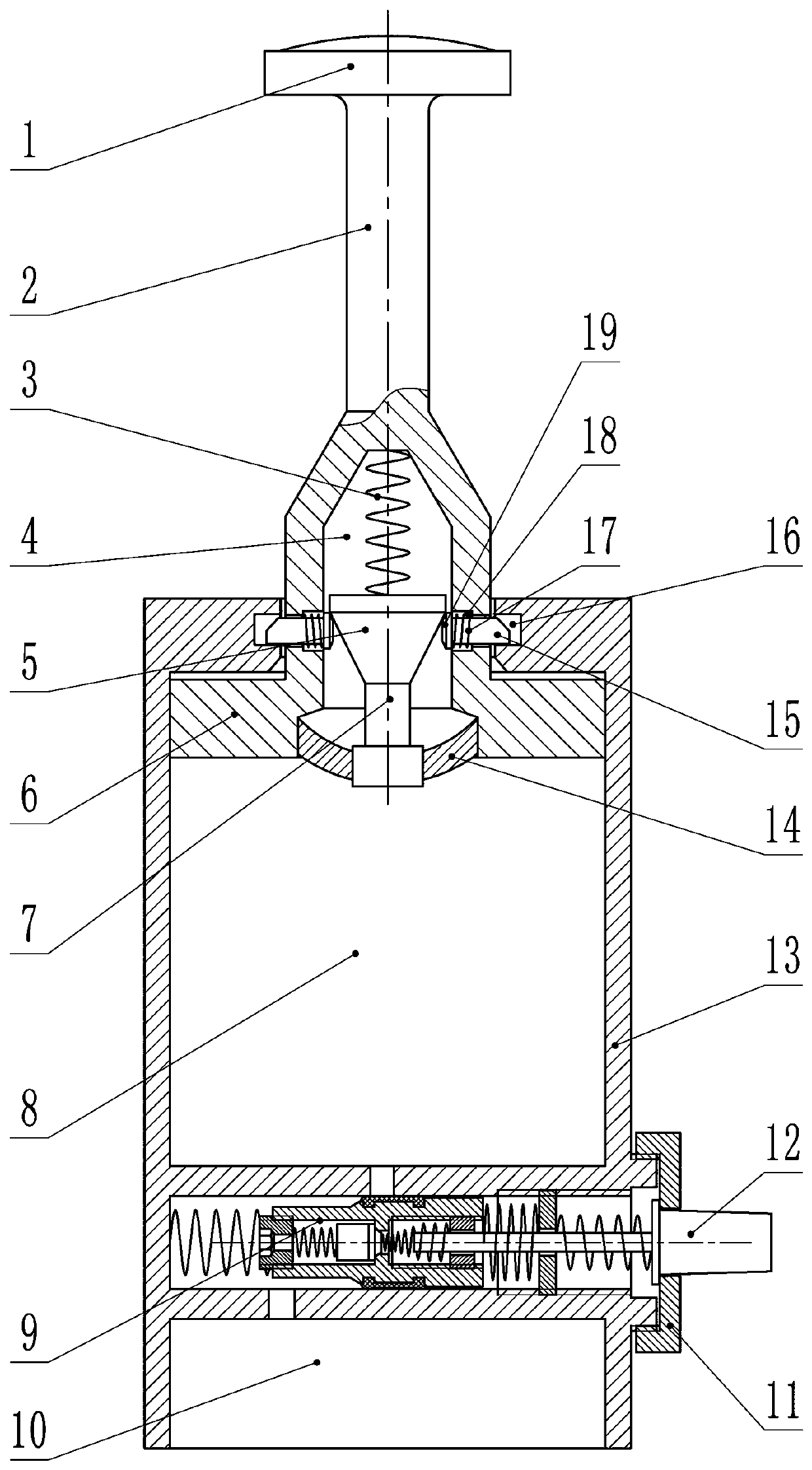

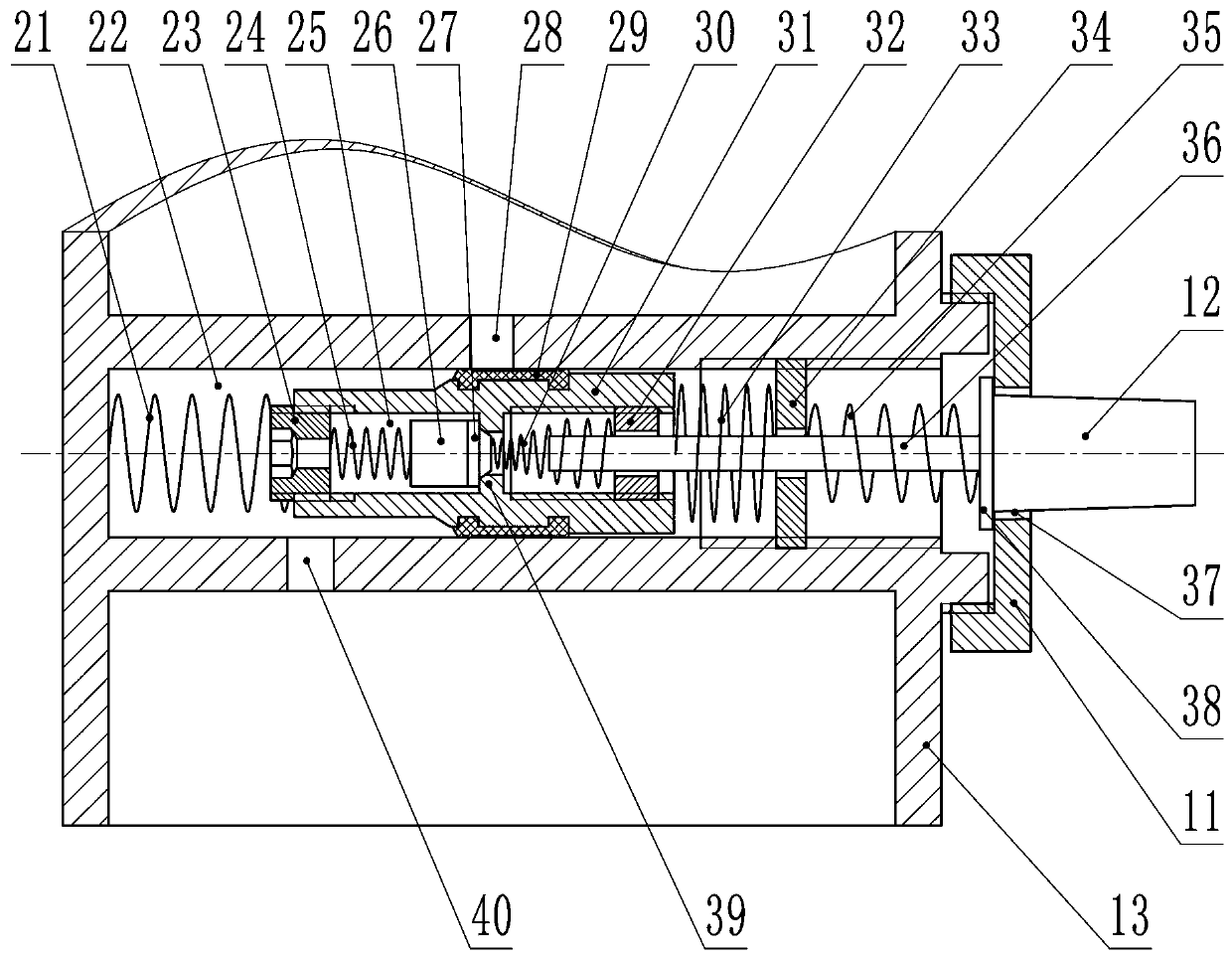

[0019] In embodiment 1, such as figure 1 , 2 , 3, the present embodiment includes a tank body 13, a valve body 9, a piston 6 and a piston rod 2. The tank body 13 is a cylinder structure with an open lower end, the valve body 9 is located in the middle of the tank body 13, and the tank body 13 is divided into two cavities, an upper chamber 8 and a lower chamber 10, by the structure of the valve body 9 . The piston 6 is located in the upper chamber 8, the periphery of the piston 6 is airtightly connected with the inner surface of the tank body 13, the piston 6 is fixedly provided with a piston rod 2, the upper wall of the tank body 13 is provided with a piston hole 20, and the piston rod 2 passes through Through the piston hole 20, the upper end of the piston rod 2 is exposed from the tank body 13, and the upper end of the piston rod 2 is provided with a piston handle 1, which can pull the piston 6 to move up and down through the action of the piston handle 1, and the upper ch...

Embodiment 2

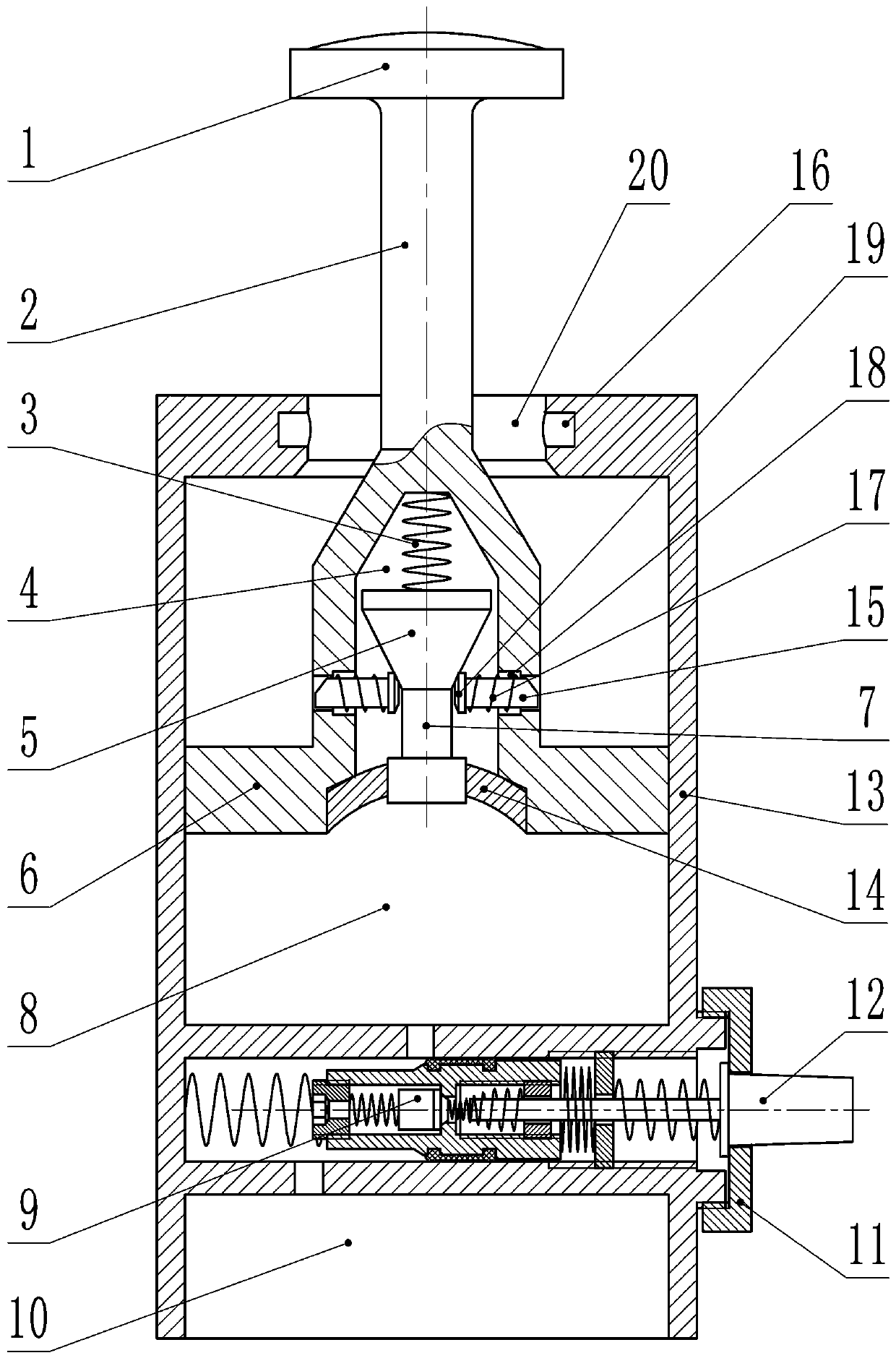

[0030] In embodiment 2, such as Figure 4 As shown, this embodiment includes a tank body 13, a valve body 9, a piston 6 and a piston rod 2, wherein the structure of the main body of the tank body 13 and the valve body 9 is the same as in Embodiment 1, and the difference between this embodiment and Embodiment 1 is the technical feature As for the structure of the upper wall of the piston 6, the piston rod 2 and the tank body 13, only the distinguishing technical features are described in this embodiment, and the same technical features as those of the first embodiment are not repeated here.

[0031] The lower end of the piston rod 2 is fixed on the piston 6, and the periphery of the piston rod 2 is provided with one or more leaf springs 41, and the upper end of the spring leaf 41 is fixedly connected with the upper end of the piston rod 2. The lower end of the spring leaf 41 is tilted outward. The diameter of the piston hole 20 on the upper wall of the tank body 13 is greater ...

Embodiment 3

[0033] In embodiment 3, such as Figure 5 As shown, this embodiment includes a tank body 13, a valve body 9, a piston 6 and a piston rod 2, wherein the structure of the main body of the tank body 13 and the valve body 9 is the same as in Embodiment 1, and the difference between this embodiment and Embodiment 1 is the technical feature As for the structure of the piston 6, the piston rod 2 and the upper wall of the tank body 13, only the distinguishing technical features will be described in this embodiment, and the same technical features as those in the first embodiment will not be described again.

[0034] Described piston 6 and piston rod 2 lower end axis places are provided with the piston cavity 4 of lower end opening, and piston rod 2 is provided with the second stepped hole 45 that communicates with piston cavity 4 and piston rod 2 outsides, and the second stepped hole 45 The position satisfies that when the piston 6 moves to the uppermost position, the outer end openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com