Disk body separation mechanism and feeding device

一种分离机构、盘体的技术,应用在输送机控制装置、输送机、机械手等方向,能够解决结构复杂、控制复杂、大空间等问题,达到控制简单、不易操作失误、节省空间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

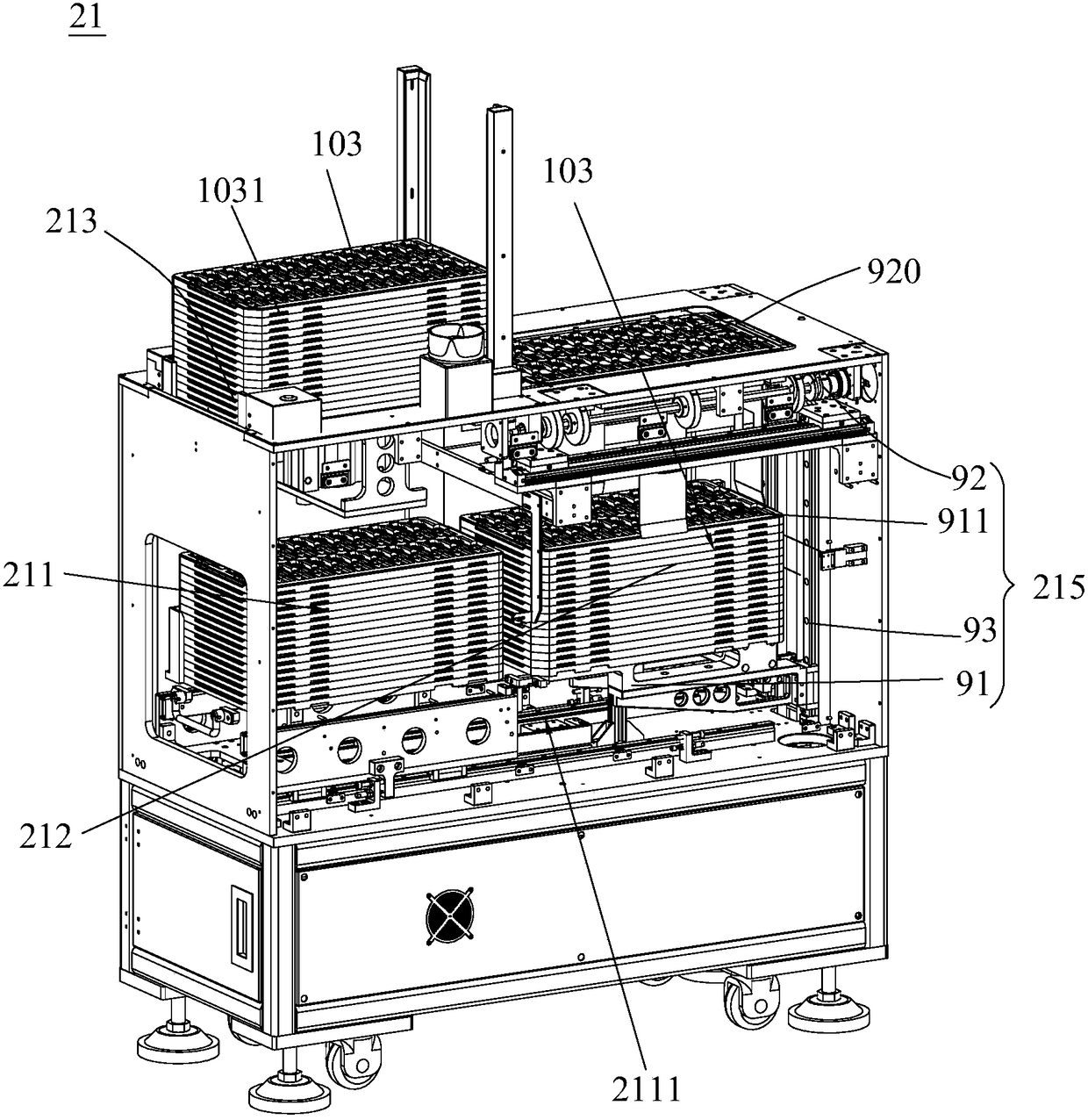

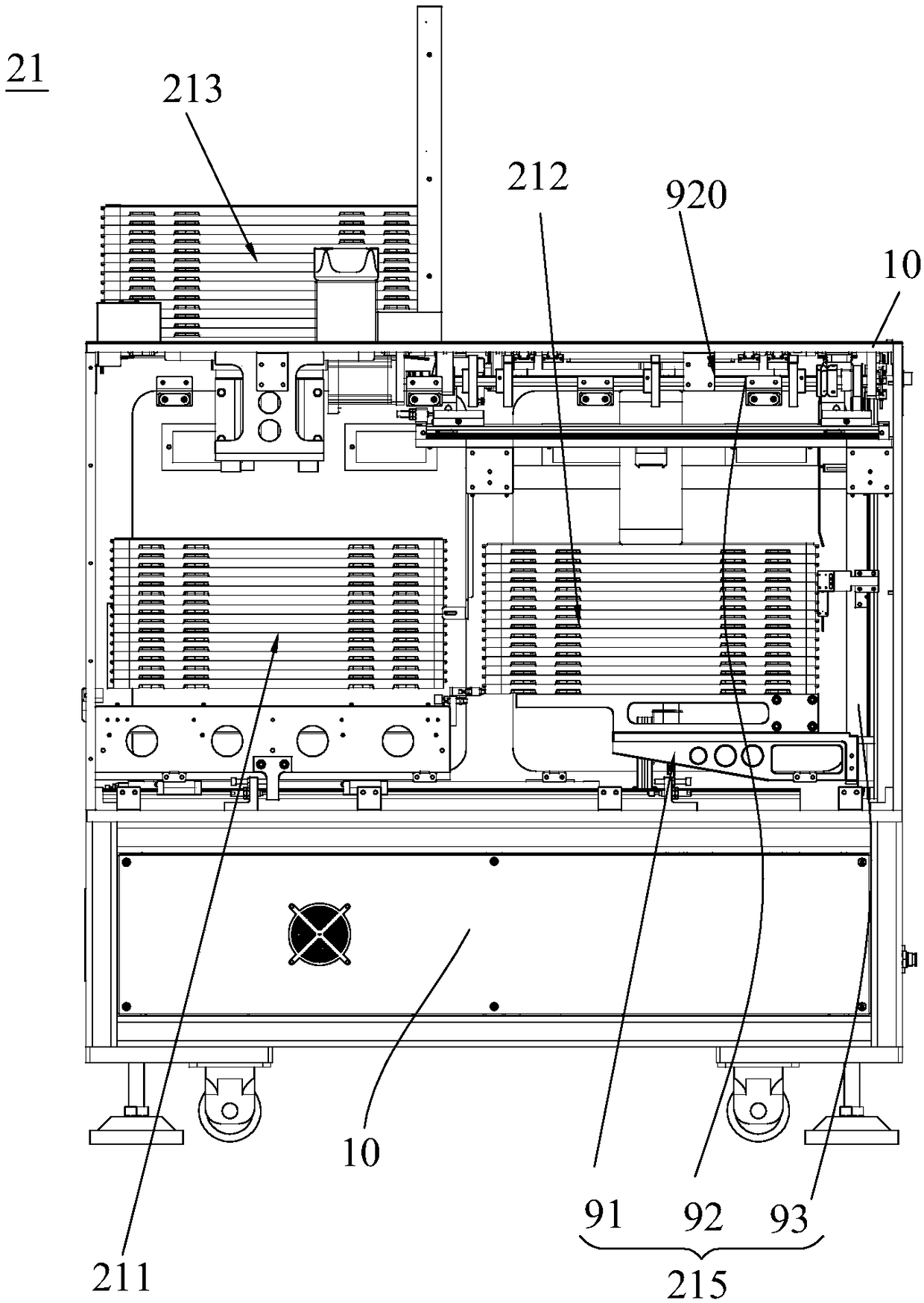

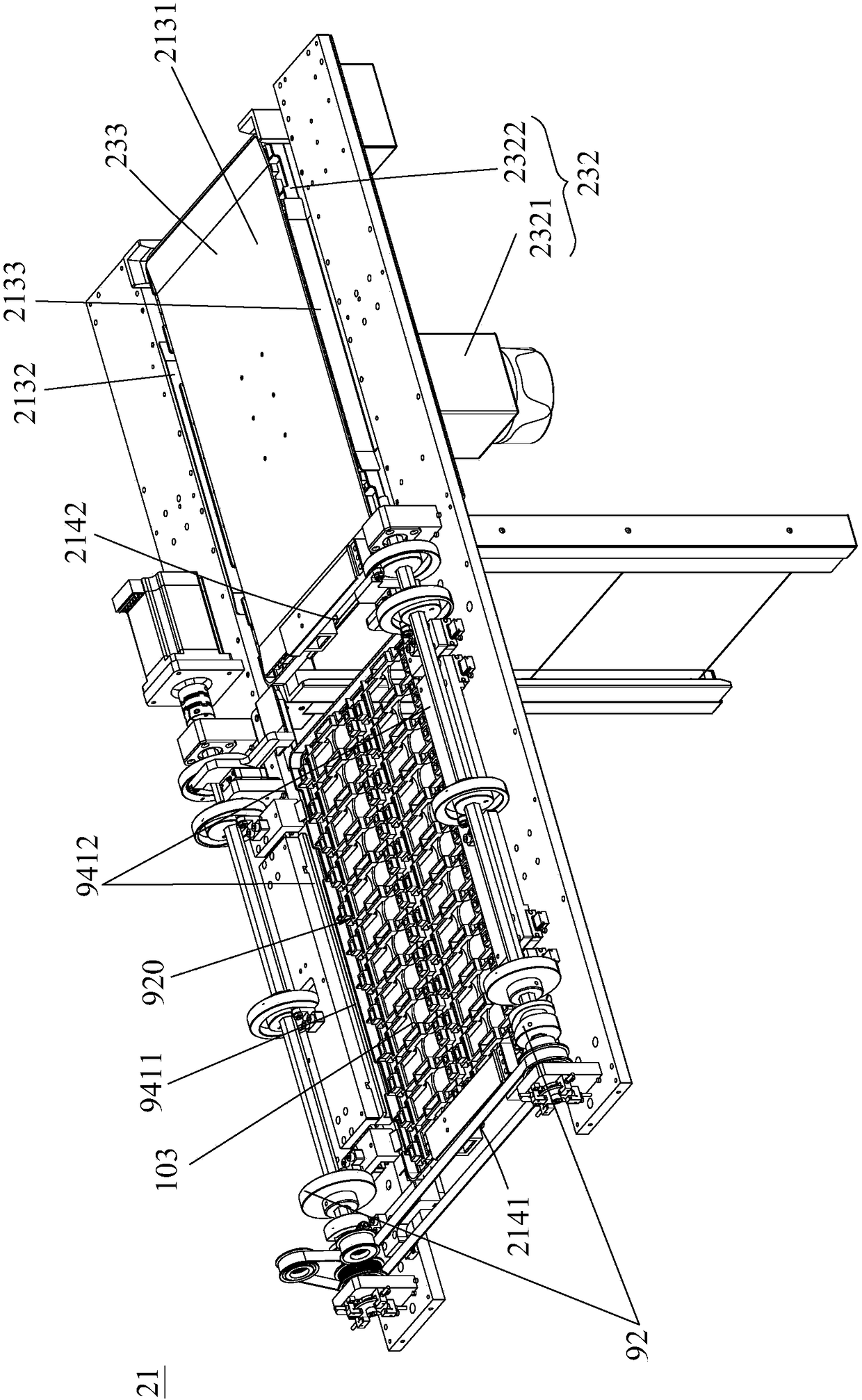

[0028] refer to figure 1 and figure 2 , the present invention discloses a feeding device 21 for feeding the production line, the feeding device 21 includes a feeding box 212 and a material shifting mechanism (2141, 2142) (such as Figure 6 As shown), a disc separation mechanism 215 is installed in the upper material box 212.

[0029] refer to figure 1 and figure 2, the disc separation mechanism 215 includes a material rack 91, a clamping assembly 92 and a lifting assembly 93, the material rack 91 has a material stacking area 911 for holding the disc 103, and a number of discs 103 are stacked on the material stacking area 911 . The clamping assembly 92 is located at the opening of the upper end of the upper material box 212 , and coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com