Enzymatic accelerated ageing method for Chinese liquor

A technology for aging and aging liquor, which is applied in the field of food manufacturing, can solve the problem that the taste of liquor is not as good as natural aging, etc., and achieve the effect of good taste, shortening aging cycle, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

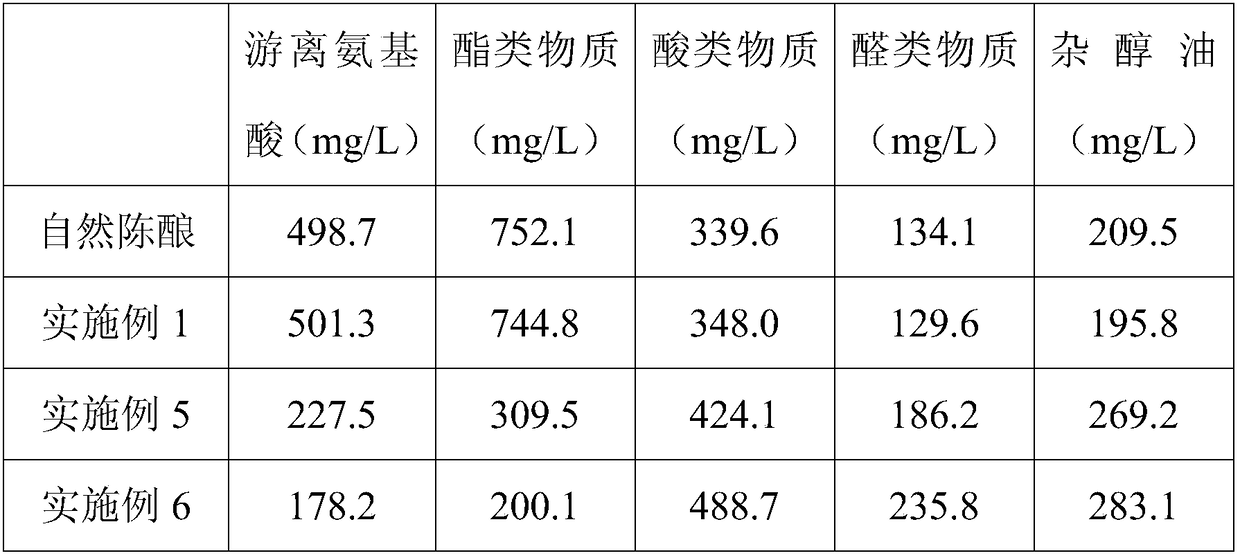

Examples

Embodiment 1

[0027] This embodiment provides a method for accelerating the aging of liquor by adding enzymes of the present invention, which specifically includes the following steps:

[0028] After adding polyphenol oxidase in the amount of 0.01g / L to new wine, ultrasonic treatment. The power of the ultrasonic treatment is 50KHz, the temperature of the liquor is controlled to be no higher than 25°C during the ultrasonic treatment, and the treatment time is 15 minutes.

[0029] The new wine after ultrasonic treatment was left to stand for 5 days, and the environmental conditions during the standstill were temperature 50° C. and relative humidity 50%.

[0030] Filter the new wine after standing still, first filter it with a sand core, then filter it with a 100 micron membrane, collect the filtrate, and obtain the matured liquor.

Embodiment 2

[0032] This embodiment provides a method for accelerating the aging of liquor by adding enzymes of the present invention, which specifically includes the following steps:

[0033] After adding polyphenol oxidase in the amount of 1g / L to new wine, ultrasonic treatment. The power of the ultrasonic treatment is 30KHz, the temperature of the liquor is controlled to be no higher than 25°C during the ultrasonic treatment, and the treatment time is 10 minutes.

[0034] The new wine after ultrasonic treatment was left to stand for 15 days, and the environmental conditions during the standstill were temperature 30° C. and relative humidity 75%.

[0035] Filter the new wine after standing still, first filter it with a sand core, then filter it with a 100 micron membrane, collect the filtrate, and obtain the matured liquor.

Embodiment 3

[0037] This embodiment provides a method for accelerating the aging of liquor by adding enzymes of the present invention, which specifically includes the following steps:

[0038] After adding polyphenol oxidase in the amount of 0.1g / L to new wine, ultrasonic treatment. The power of the ultrasonic treatment is 45KHz, the temperature of the liquor is controlled to be no higher than 25°C during the ultrasonic treatment, and the treatment time is 12 minutes.

[0039] The new wine after ultrasonic treatment was left to stand for 10 days, and the environmental conditions during the standstill were temperature 40° C. and relative humidity 60%.

[0040] Filter the new wine after standing still, first filter it with a sand core, then filter it with a 10-micron membrane, collect the filtrate, and obtain the aged liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com