A method for separating zinc from zinc-containing dust sludge in an iron and steel plant

A technology for iron and steel plants and dust sludge, which is applied in the field of zinc-containing dust and sludge separation in iron and steel plants, can solve the problems of harsh operating environment, large ammonia loss, and serious ammonia volatilization, and achieve good operating environment, efficient separation, and reduced zinc content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

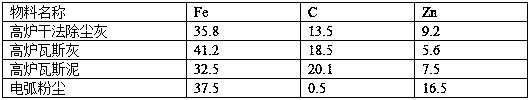

[0025] The method for separating zinc from zinc-containing dust and sludge in the iron and steel plant, the concrete steps are as follows:

[0026] Step 1, prepare 4000mL ammonium carbonate and ammonium bicarbonate mixed solution, control the molar ratio of ammonium carbonate and ammonium bicarbonate in the mixed solution to be 1:1, and the total ammonia concentration is 4mol / L

[0027] Step 2, the blast furnace gas ash (the phase of zinc in the blast furnace gas ash includes metal zinc, ZnO, ZnS, ZnFe 2 o 4 and Zn 2 SiO 4 , the mass percent of the main chemical components are: Zn3.5%, Fe38.2%, C17.3%, CaO2.1%, SiO 2 3.5%) according to the solid-to-liquid ratio of 1:4g / mL, add the mixed solution of ammonium carbonate and ammonium bicarbonate in step 1, mix evenly and add it to the high-pressure reactor, and feed compressed air into the high-pressure reactor to maintain the pressure in the reactor. 2.0MPa, heat up, control the reaction temperature to 120°C, and the leaching...

Embodiment 2

[0030] The method for separating zinc from zinc-containing dust and sludge in the iron and steel plant, the concrete steps are as follows:

[0031] Step 1, prepare 8000mL of ammonium carbonate and ammonium bicarbonate mixed solution, control the molar ratio of ammonium carbonate and ammonium bicarbonate in the mixed solution to be 2:1, and the total ammonia concentration is 6mol / L

[0032] Step 2, blast furnace gas mud (the phase of zinc in blast furnace gas mud includes metal zinc, ZnO, ZnS, ZnFe 2 o 4and Zn 2 SiO 4 , the mass percentage of the main chemical composition is: Zn10.2%, Fe36.5%, C19.1%, CaO1.9%, SiO 2 2.7%) according to the solid-to-liquid ratio of 1:8g / mL, add the mixed solution of ammonium carbonate and ammonium bicarbonate in step 1, mix evenly and add to the autoclave, and feed compressed air into the autoclave to maintain the pressure in the autoclave. 0.5MPa, heat up, control the reaction temperature to 80°C, and the leaching reaction time is 180min. Af...

Embodiment 3

[0035] The method for separating zinc from zinc-containing dust and sludge in the iron and steel plant, the concrete steps are as follows:

[0036] Step 1, prepare 15000mL of ammonium carbonate and ammonium bicarbonate mixed solution, control the molar ratio of ammonium carbonate and ammonium bicarbonate in the mixed solution to be 4:1, and the total ammonia concentration is 10mol / L

[0037] Step 2, dry blast furnace dedusting (the phase of zinc in the blast furnace dry dedusting ash includes metal zinc, ZnO, ZnS, ZnFe 2 o 4 and Zn 2 SiO 4 , the mass percentage of the main chemical composition is: Zn12.5%, Fe30.2%, C18.5%, CaO 4.3%, SiO 2 7.5%) according to the solid-to-liquid ratio of 1:20g / mL, add the mixed solution of ammonium carbonate and ammonium bicarbonate in step 1, mix evenly and add it to the high-pressure reactor, and feed compressed air into the high-pressure reactor to maintain the pressure in the reactor. 0.12MPa, heat up, control the reaction temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com