Self-pushing launching device for improving initial volume of low pressure chamber

A launching device and self-bombing technology, applied in the field of self-bombing launch devices, can solve the problems of high missile bottom temperature, high launch tube pressure, and excessive missile overload, so as to reduce the bottom temperature of the missile and reduce the missile overload. , reduce the effect of inner overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

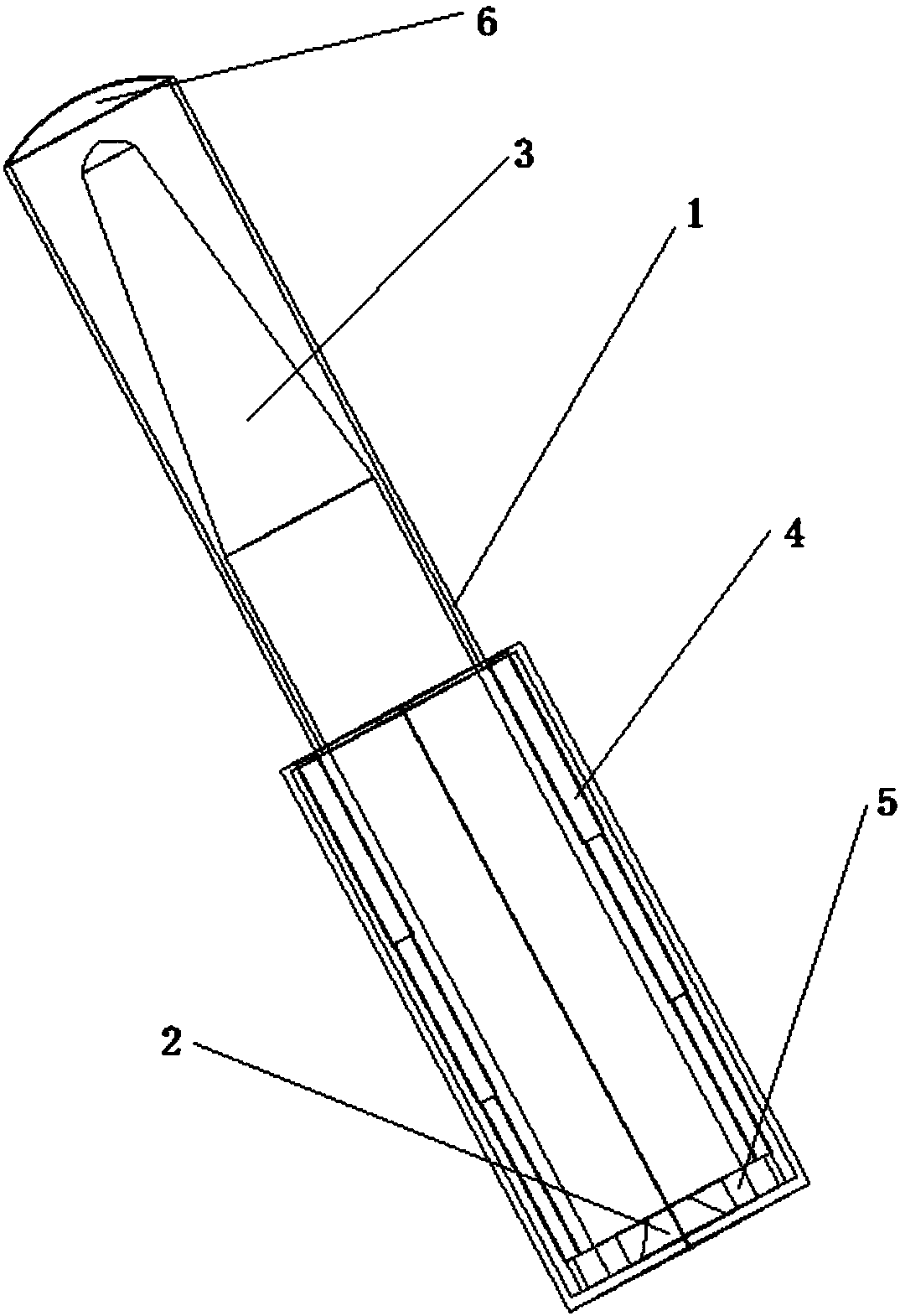

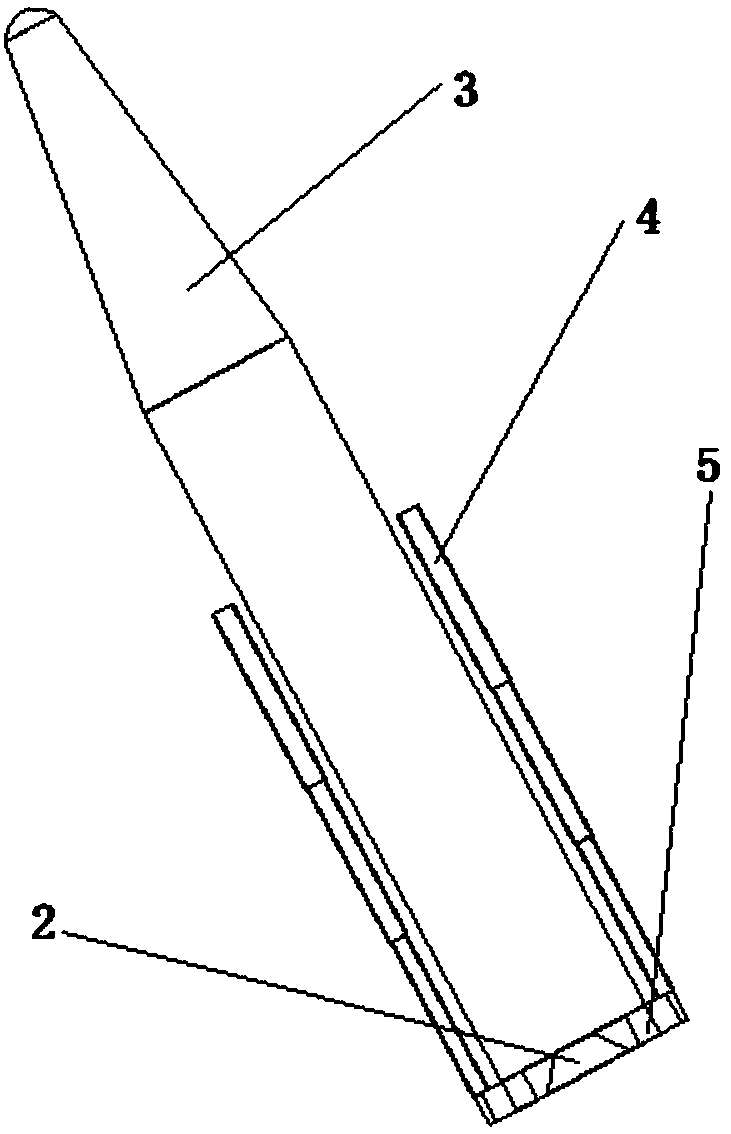

[0026] This embodiment provides a self-bouncing launching device for increasing the initial capacity of the low-pressure chamber, see the attached figure 1 , including: launch tube 1, missile 3, hydraulic cylinder 4, supporting plate 5 and launch tube cover 6;

[0027] One end of the launch tube 1 is a circular tube, and the other end is a square tube;

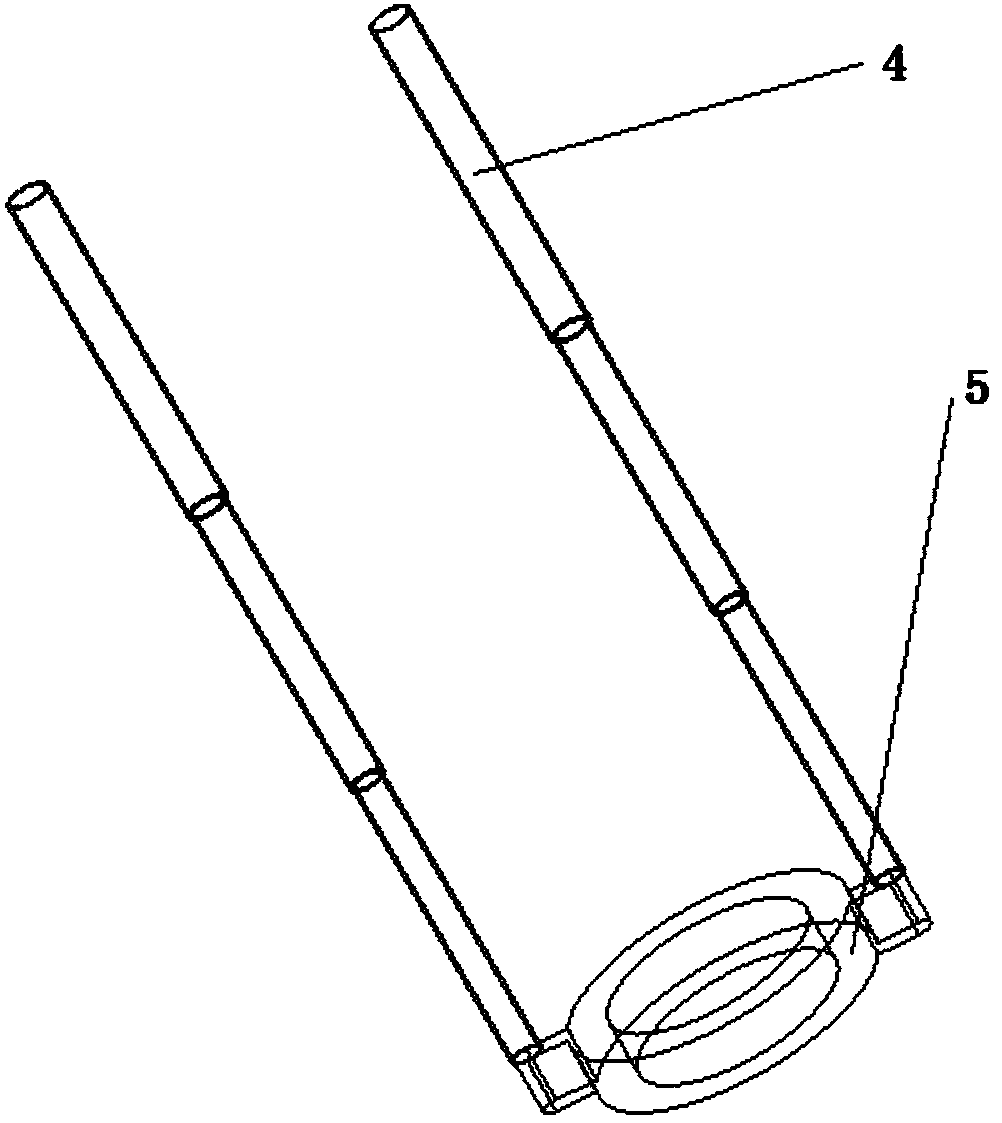

[0028] The hydraulic cylinder 4 is a three-stage cylinder;

[0029] The supporting plate 5 is an annular structure;

[0030] The overall connection relationship is as follows: see attached figure 2 , the two hydraulic cylinders 4 are located at two opposite corners in the square tube of the launch tube 1, and the cylinder ends are all fixed on the step surface at the intersection of the square tube and the circular tube of the launch tube 1, and the piston rod The end is connected as a whole with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com