Bearing dynamic friction torque tester

A technology of friction torque and tester, applied in the field of testing, to achieve the effect of simple structure, smooth speed and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below.

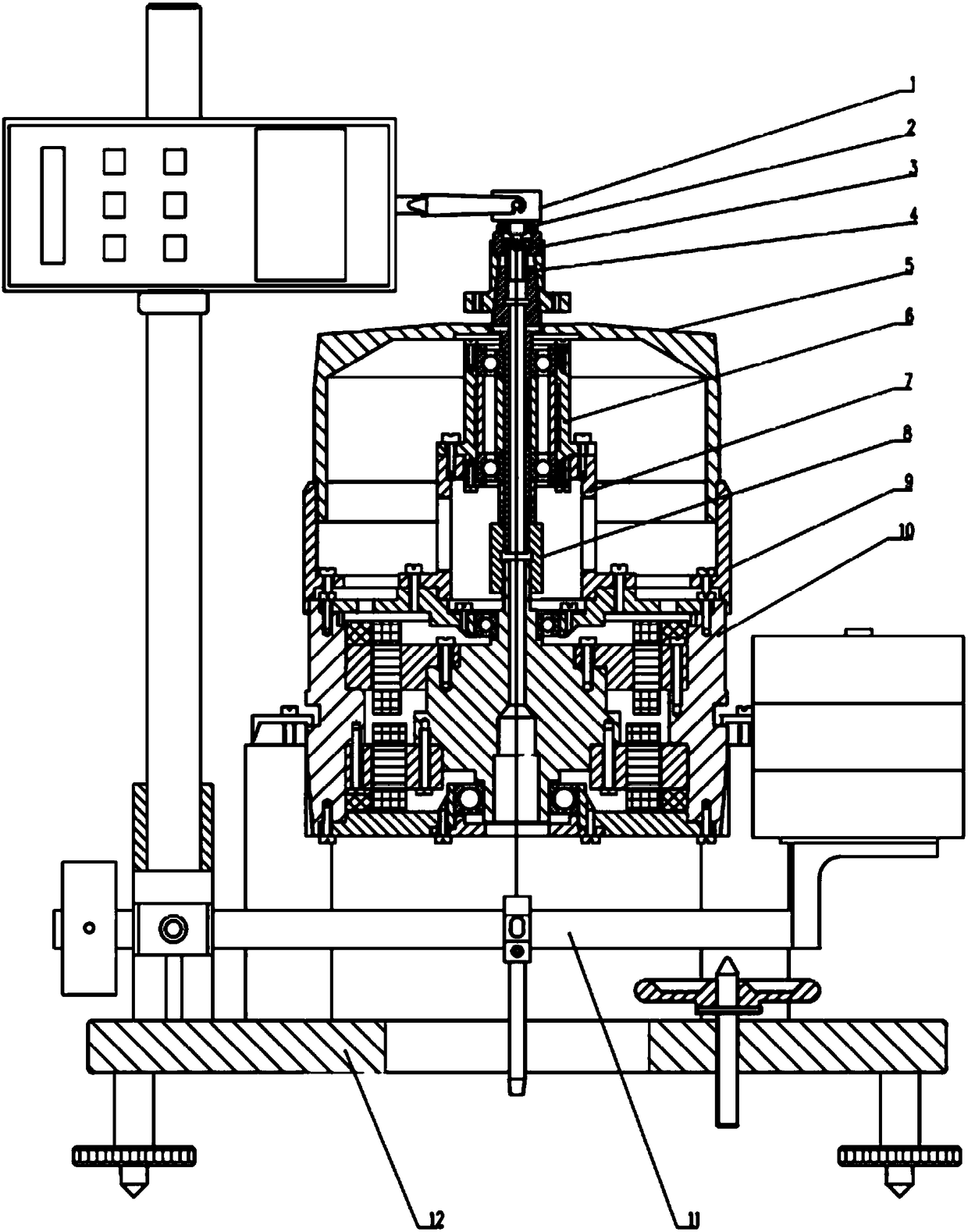

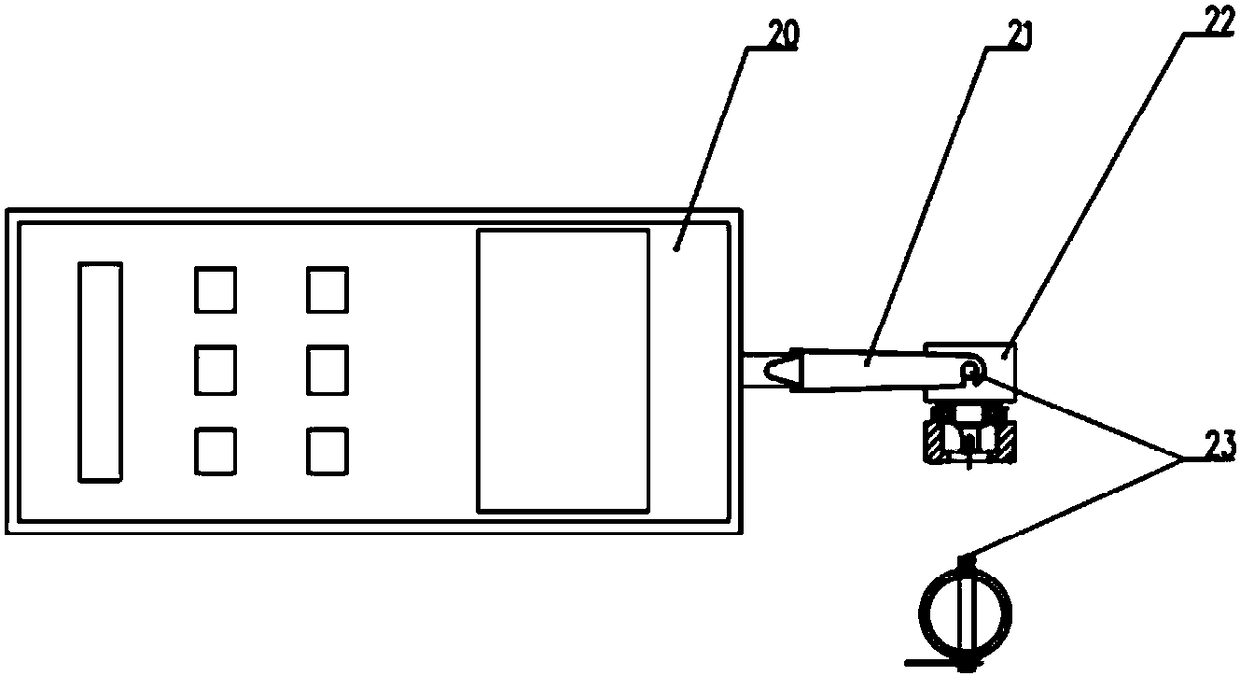

[0035] The host structure diagram of the present invention can be found in figure 1 . Bearing dynamic friction torque tester, the host includes torque measuring mechanism 1, tested bearing 2, tested bearing seat 3, lock nut 4, upper cover 5, precision spindle assembly 6, spindle seat 7, diaphragm coupling 8 , Middle casing 9, driving mechanism 10, loading mechanism 11 and base assembly 12.

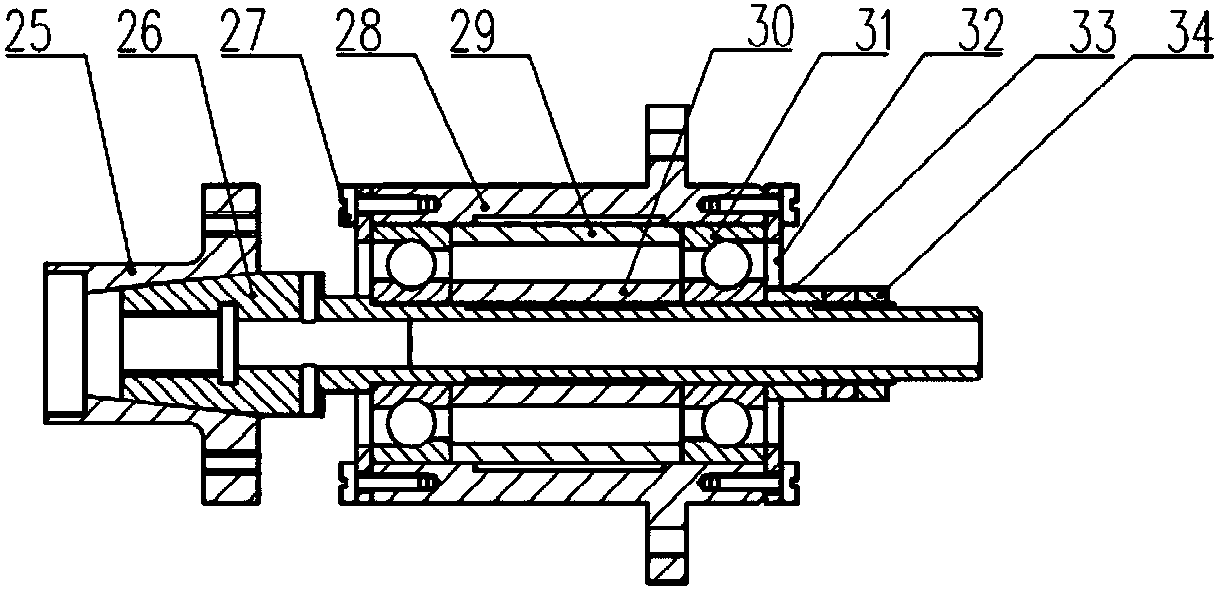

[0036] The torque measuring mechanism 1 is installed on the column 68 of the base assembly 12; the bearing seat 3 to be tested is installed in the positioning cone seat 25 at the top of the precision spindle assembly 6, and locked with the lock nut 4; the upper casing 5 is installed in the middle casing 9, fastened with radial screws; the middle cover 9 is installed on the driving mechanism 10, and fastened with screws; the main shaft seat 7 is installed on the upper end cover 38 of the driving mechanism 10, and fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com