Sensorless control method for triangle connection permanent magnet synchronous motor and verification system thereof

A permanent magnet synchronous motor, triangular technology, applied in the field of electric power transmission, can solve the problems of reduction and motor heating efficiency, and achieve the effects of continuous speed, smooth angle, good dynamic response ability and steady-state anti-load interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

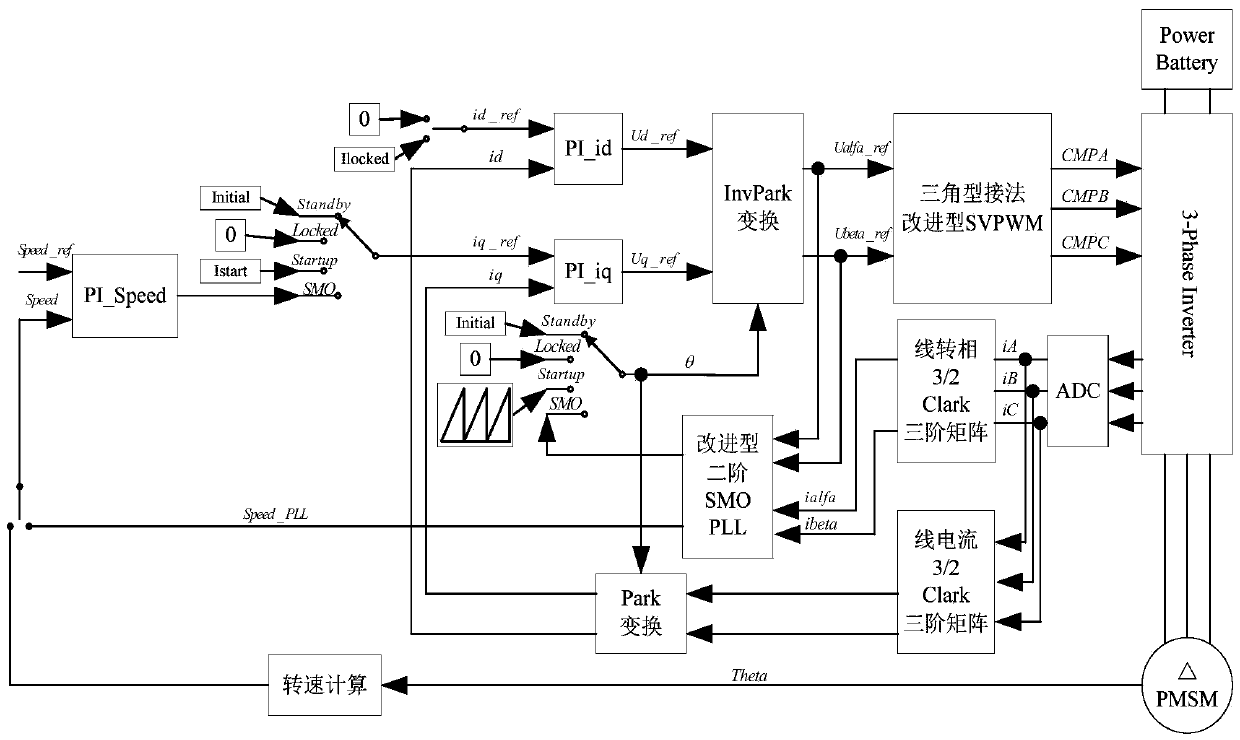

[0077] The method for controlling the delta-connected permanent magnet synchronous motor without a position sensor of the present invention comprises the following steps:

[0078] (1) Carry out the pulse width modulation output of the delta connection permanent magnet synchronous motor;

[0079] (2) Carry out the coordinate transformation of the delta-connected permanent magnet synchronous motor without position sensor control;

[0080] (3) Carry out second-order improved coupled sliding mode position estimation.

[0081] As a preferred embodiment of the present invention, described step (1) specifically includes the following steps:

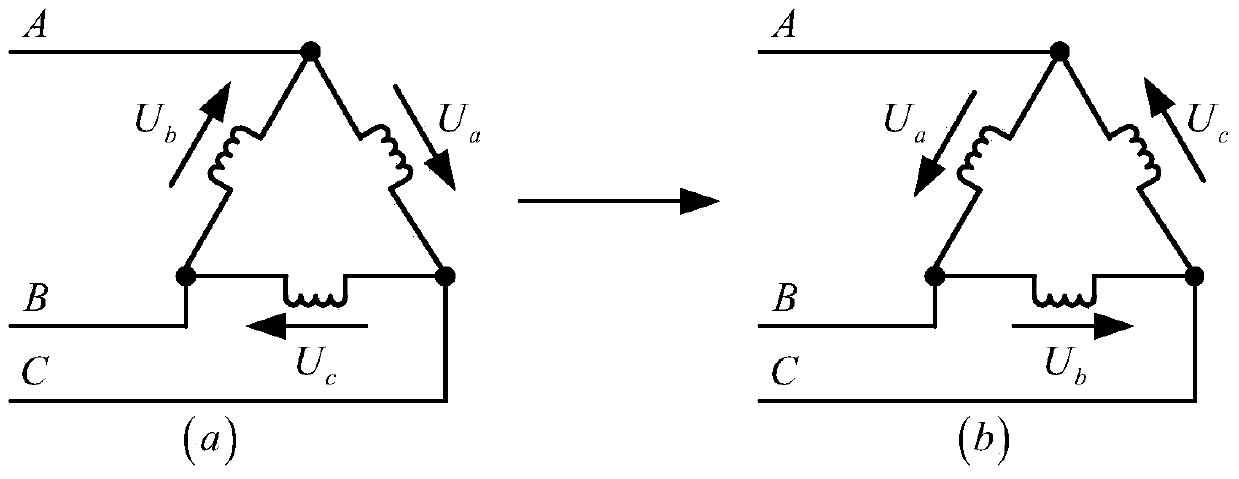

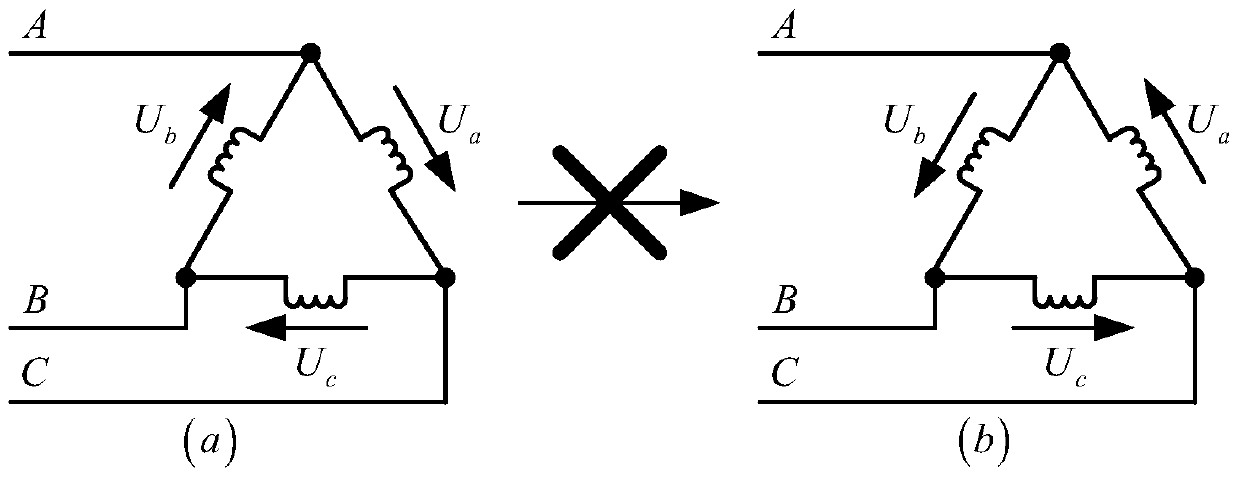

[0082] (1.1) Determine the phase voltage direction of the delta-connected permanent magnet synchronous motor;

[0083] (1.2) Determine the phase angle offset of the voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com