Curve design method for large-ellipticity piston excircle profile

A kind of curve design, large ellipse technology, applied in the direction of piston, mechanical equipment, machine/engine, etc., can solve the problems such as the adverse effect of the shape accuracy of the processed curve, discontinuous acceleration, etc., to avoid sudden acceleration of acceleration, continuous displacement curve, and improve processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

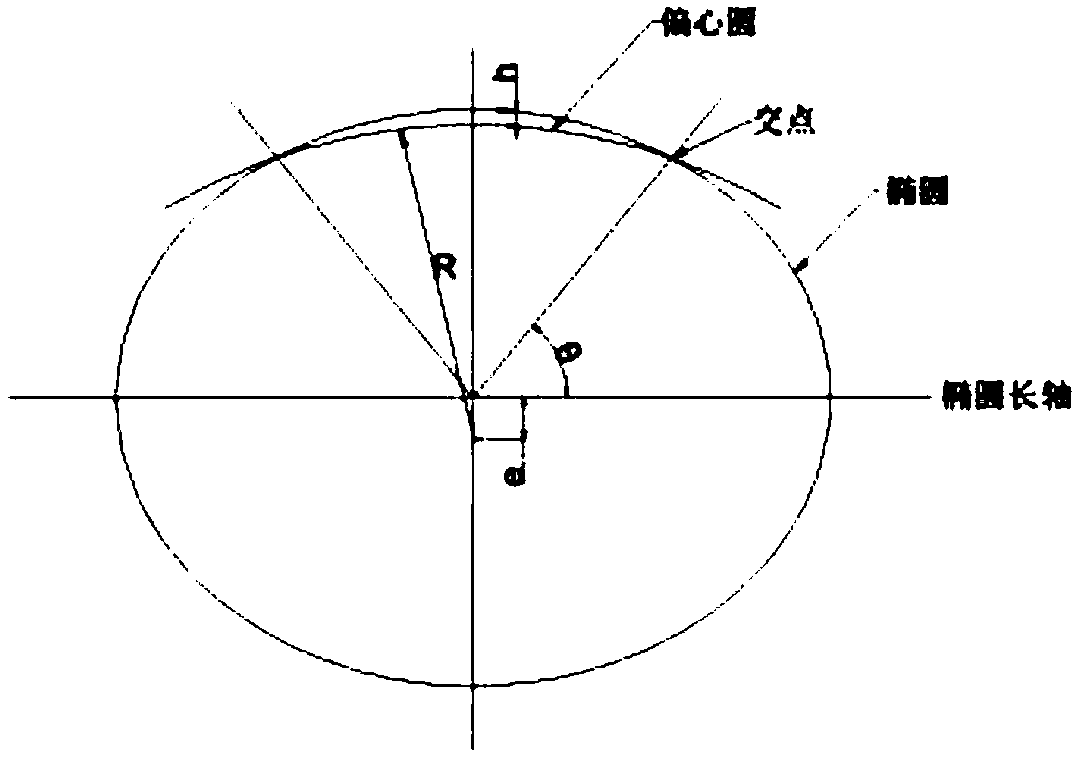

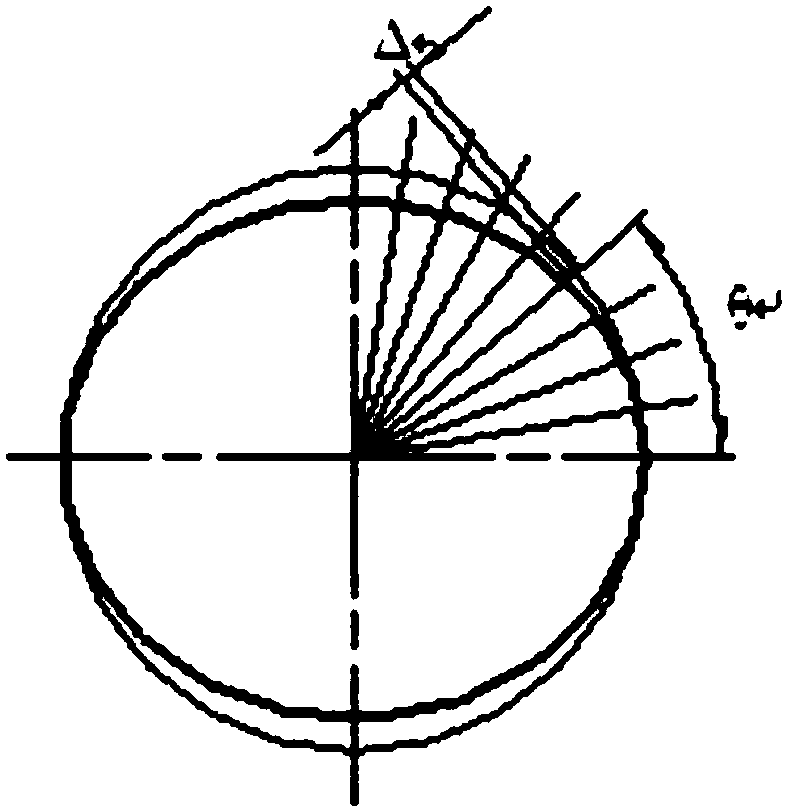

[0062]The invention discloses a method for designing the outer circle profile curve of a piston with large ellipticity, which adopts an ellipse superimposed cycloid composite curve, and the cycloid is also called a sinusoidal acceleration curve, and the acceleration characteristic of the curve is a sinusoidal curve. The combination curve of ellipse superimposed cycloid can avoid the sudden sudden change of acceleration at the intersection point θ, and reduce the impact of the processing process. Include the following steps:

[0063] In step 1, the center of the cross-section of the piston skirt is used as the center of the ellipse, the diameter D of the major axis of the piston skirt is used as the major axis of the ellipse, and the minor axis of the ellipse is determined by the ellipticity G of the piston skirt;

[0064] Step 2: Make an eccentric circle on the short axis of the piston skirt, the angle formed by the intersection point of the ellipse and the eccentric circle is...

Embodiment 2

[0078] The expression of elliptical linear acceleration is:

[0079] 0-θ elliptical acceleration expression: such as formula (4)

[0080] θ-90° elliptical acceleration expression:

[0081]

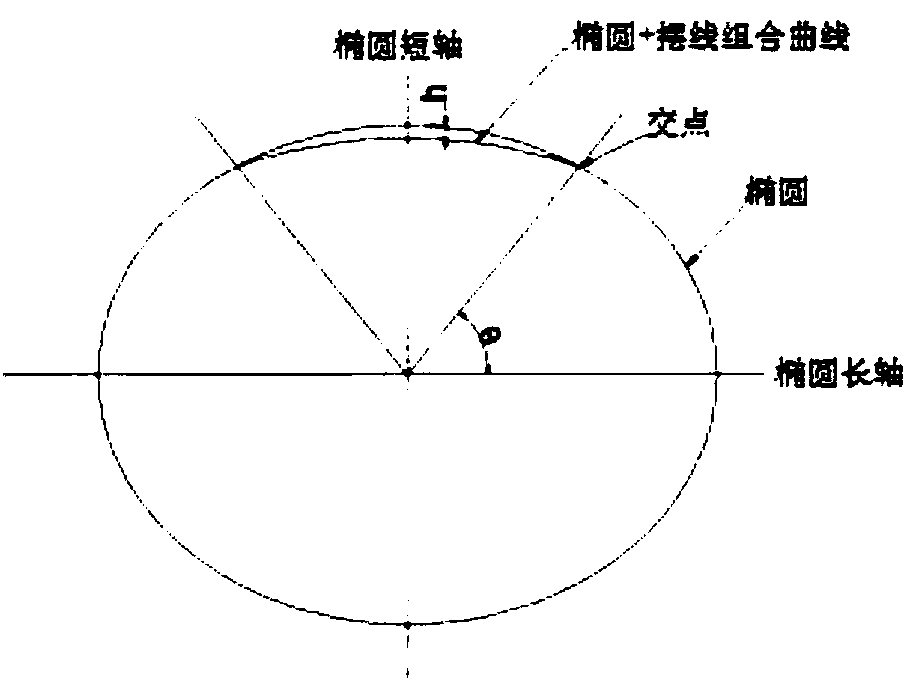

[0082] The sudden change of acceleration is due to the instantaneous increase of H in the formula (5), so the gradient elliptical line with quadratic sinusoidal change is used instead of the eccentric circular line, and the displacement, velocity and acceleration at the cusp of the combined curve are smoothly transitioned.

[0083] A method for designing the outer circle profile curve of a piston with large ellipticity, using ellipse superimposed gradient ellipse combined curve, comprising the following steps:

[0084] In step 1, the center of the cross-section of the piston skirt is used as the center of the ellipse, the diameter D of the major axis of the piston skirt is used as the major axis of the ellipse, and the minor axis of the ellipse is determined by the ellipticity G of the...

Embodiment 3

[0098] Taking intersection angle θ=54°, eccentric distance e=2.44, offset of eccentric circle relative to the semi-minor axis of ellipse h=0.4, and ellipticity G=0.3 as the simulation experiment conditions, the combination of "ellipse + eccentric circle" is obtained Curve characteristics such as Figure 5(a)-Figure 5(d) As shown, the curve characteristics of the combination of "ellipse + ellipse" are as follows Figure 6(a)-Figure 6(d) As shown, the curve characteristics of the combination of "ellipse + cycloid" are as follows Figure 7(a)-Figure 7(d) As shown, the curve characteristics of the combination of "ellipse + gradient ellipse" are as follows Figure 8(a)-Figure 8(d) shown.

[0099] The comparative experiment spindle speed was 800 rpm.

[0100] Table 1 Comparison of motion law characteristics of four methods

[0101]

[0102] Through comparison, the following conclusions are drawn:

[0103] (1) The time-varying curves of displacement, velocity, acceleration an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com