Sine force online calibration device based on piezoelectric ceramics

A calibration device, piezoelectric ceramic technology, applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of inability to achieve online calibration, difficulty in disassembling and assembling the calibrated sensor, and achieve high real-time accuracy, high natural frequency, and improved The effect of calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

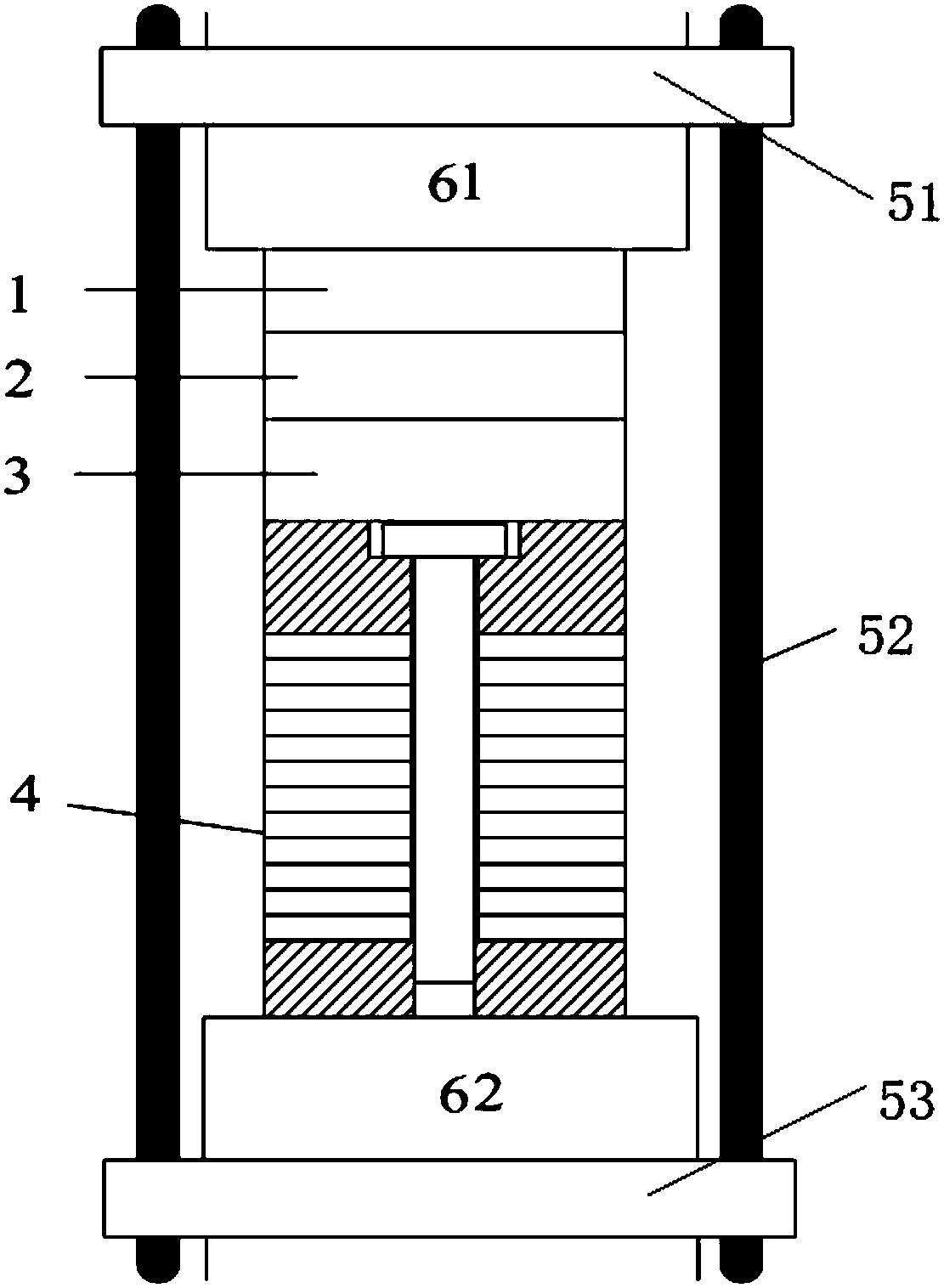

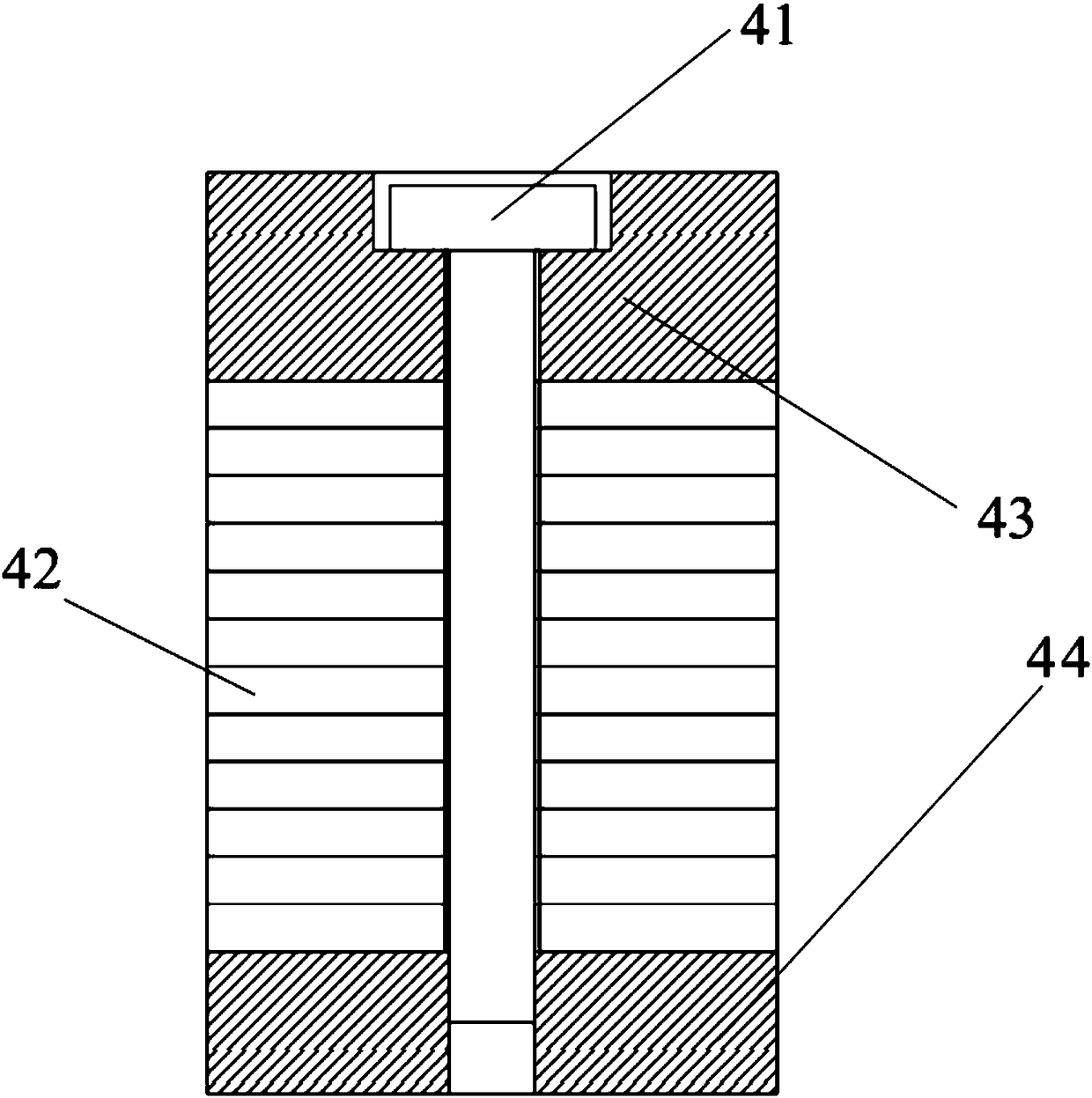

[0016] Such as figure 1 As shown, the sinusoidal force online calibration device based on piezoelectric ceramics, the calibration device and the sensor 1 to be calibrated are integrated between the first part 61 and the second part 62, the calibration device includes a force transmission block 2, a standard force sensor 3, a pressure sensor The electric stack 4 and the locking mechanism 5, the force transmission block 2, the standard sensor 3 and the piezoelectric stack 4 are sequentially stacked and fixed, the force transmission block 2 is located between the calibrated sensor 1 and the standard sensor 3, and the locking mechanism 5 locks Tighten the first part 61 and the second part 62.

[0017] The first part 61 and the second part 62 refer to two connected parts connected by the sensor 1 to be calibrated. The space between the first component 61 and the second component 62 for accommodating the present invention may be reserved at the beginning of the design of the calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com