Single-phase capacitor variable electrostatic motor

A variable and capacitive technology, applied in the direction of electrostatic motor, electrostatic generator/motor, generator/motor, etc., can solve the problems of increasing complexity and achieve the effect of simple structure, high efficiency and small motor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

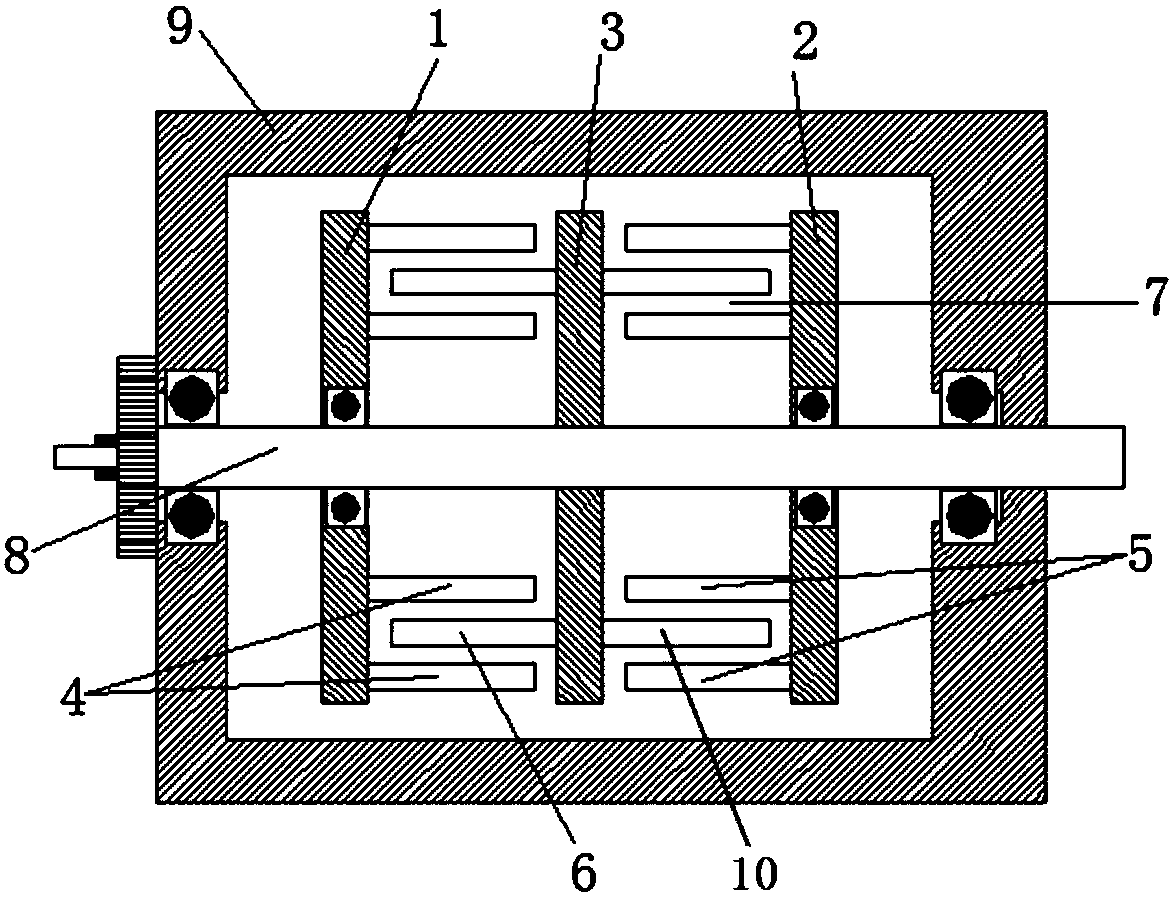

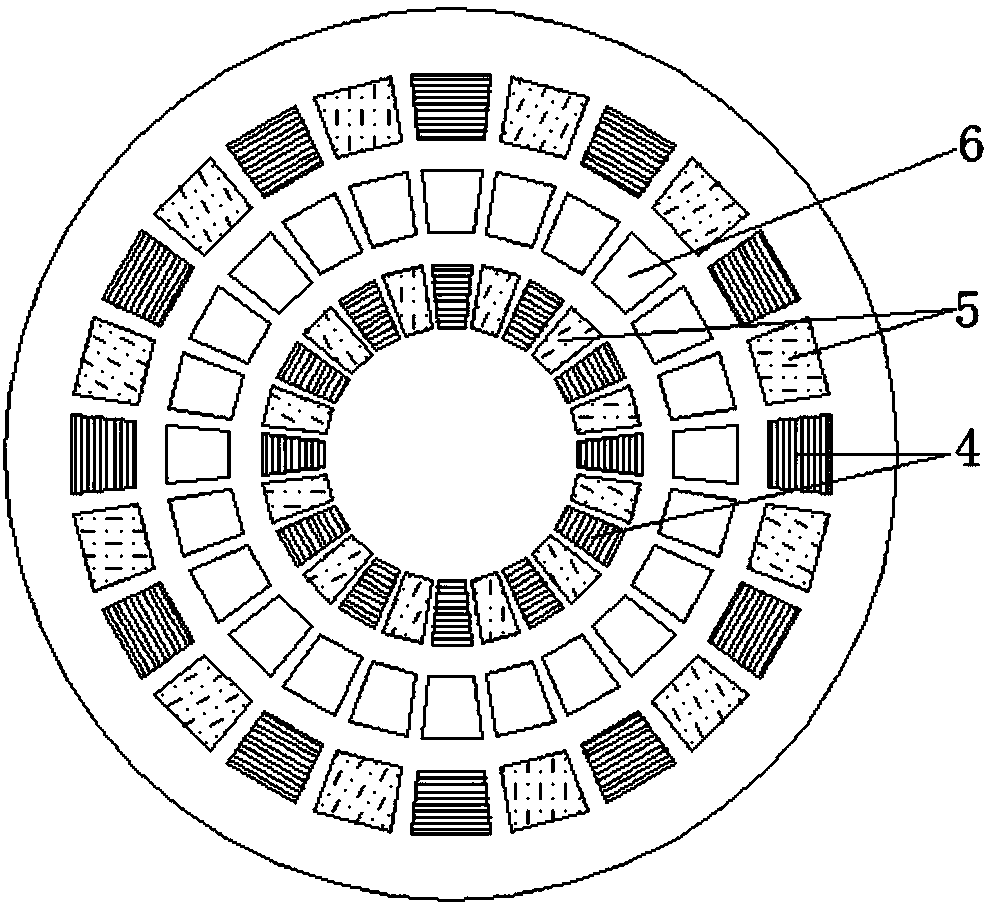

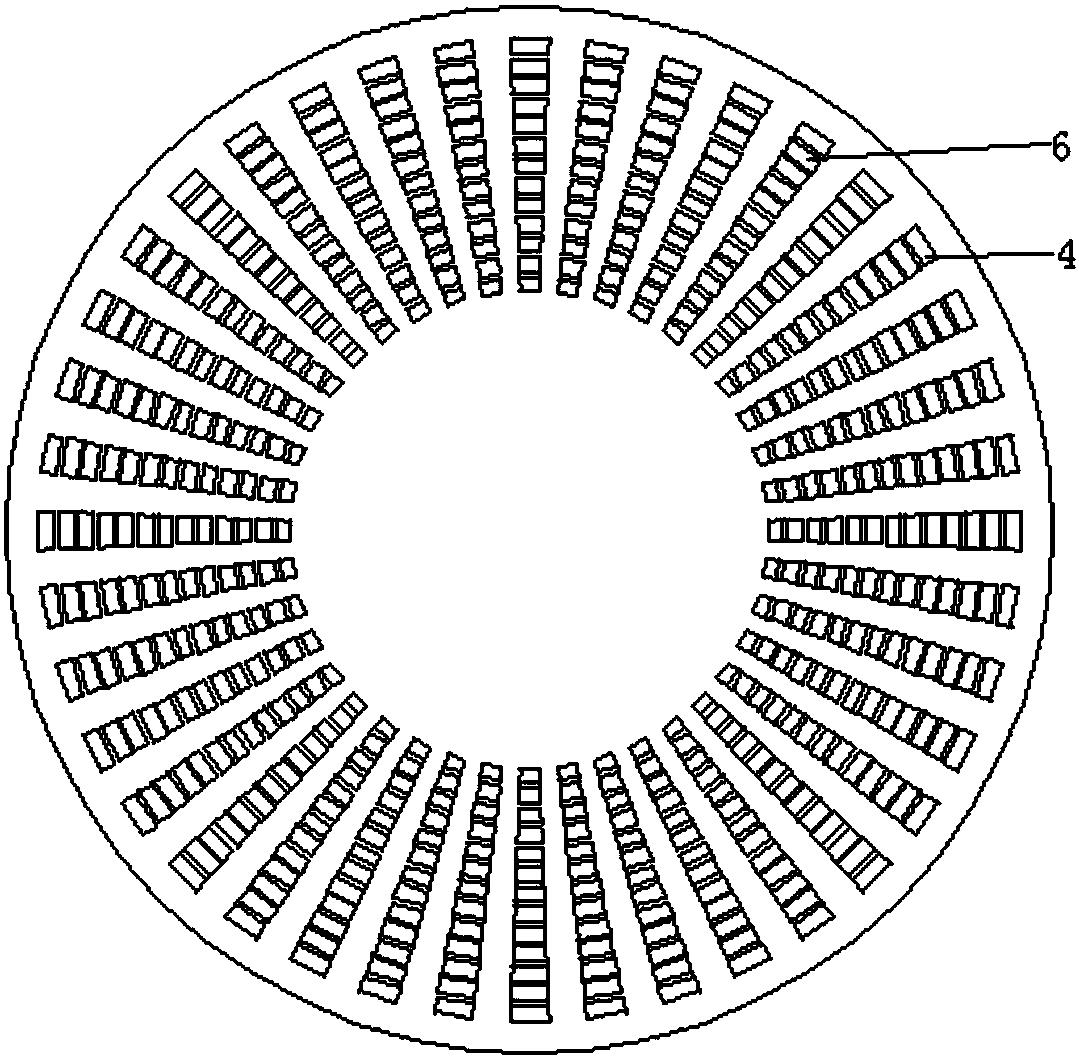

[0031] This embodiment takes a single-phase stator / rotor capacitance variable electrostatic motor as an example, refer to image 3 , the variable capacitance electrostatic motor includes a first stator 1, a second stator 2 and a rotor 3, the first stator 1, the second stator 2 and the rotor 3 are arranged axially, and the rotor 3 is located at the first stator 1 Between the second stator 2, there are several first electrode layers distributed along concentric circles on the first stator 1, the number of layers of the first electrode layer is 7, and the number of first electrodes 4 in each first electrode layer is 40 ; On the second stator 2, some second electrode layers are distributed along the concentric circles, the number of layers of the second electrode layers is 7, and the quantity of the second electrodes 6 in each second electrode layer is 40; the rotor 3 is arranged along the concentric circles A number of third electrode layers are distributed, and the number of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com