Novel drying tower

A drying tower, a new type of technology, applied to evaporator accessories, spray evaporation, etc., can solve the problems of increasing equipment operation and maintenance costs, high-temperature dry particle scaling accumulation, and difficult scaling work, achieving compact structure and high production efficiency , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

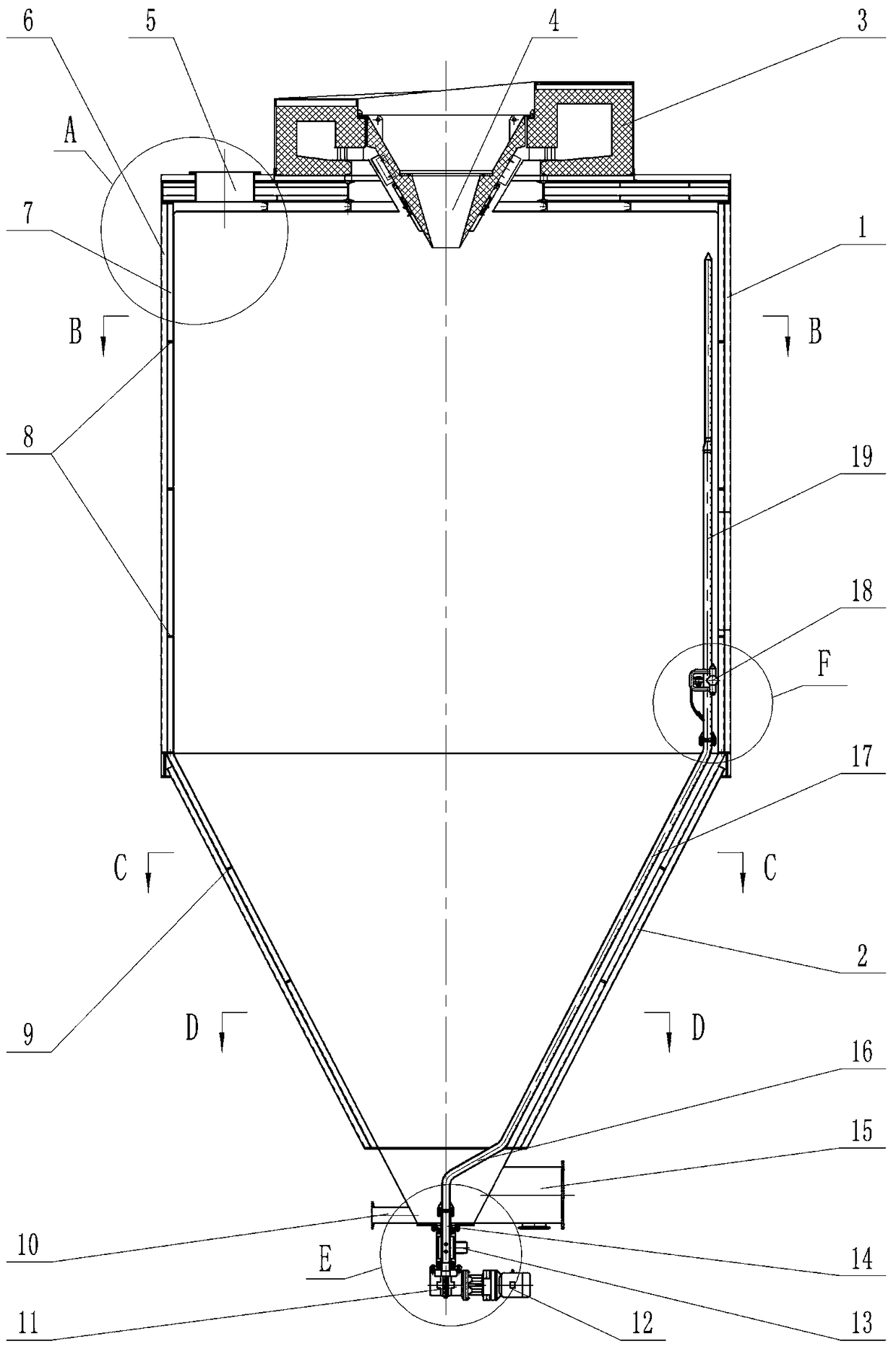

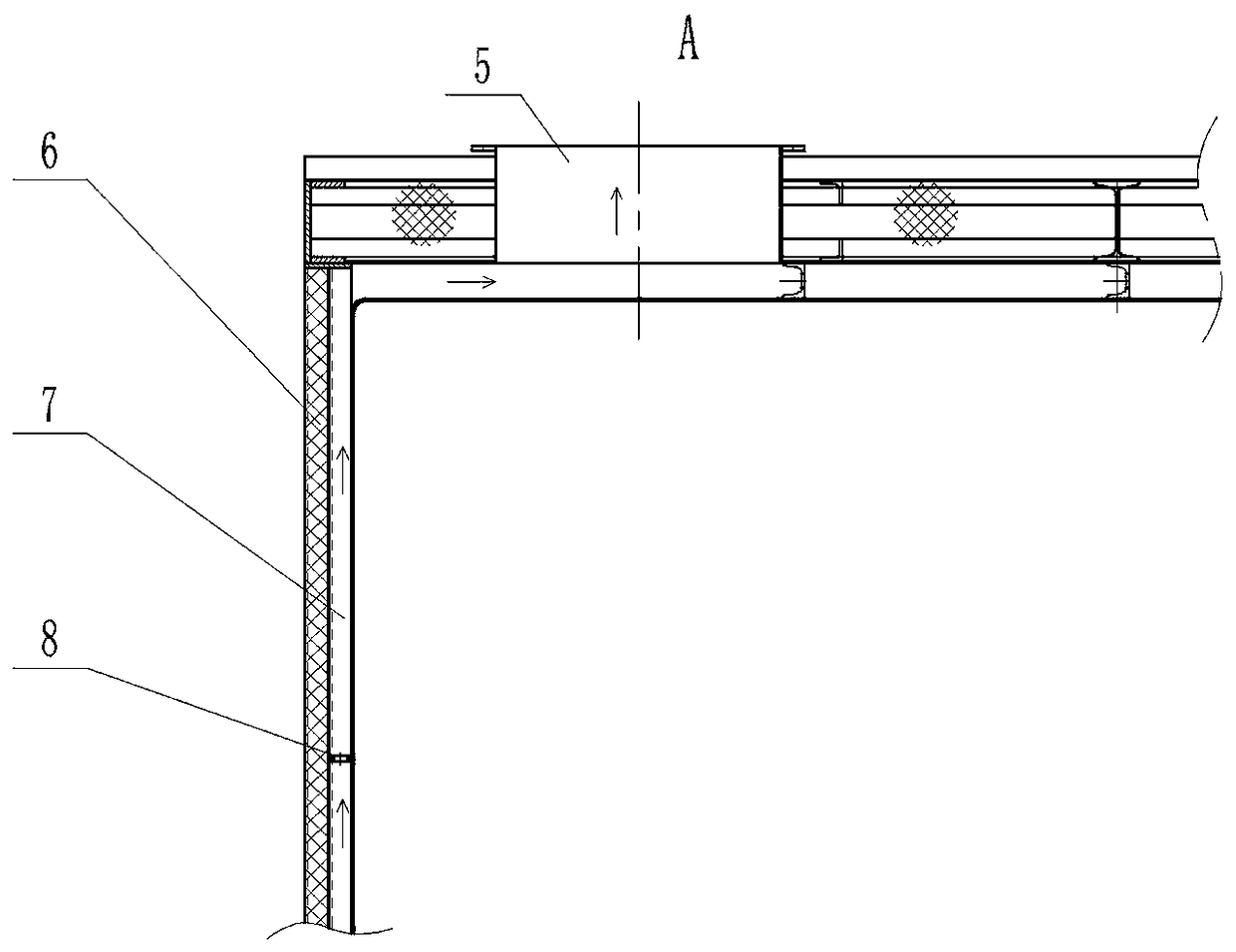

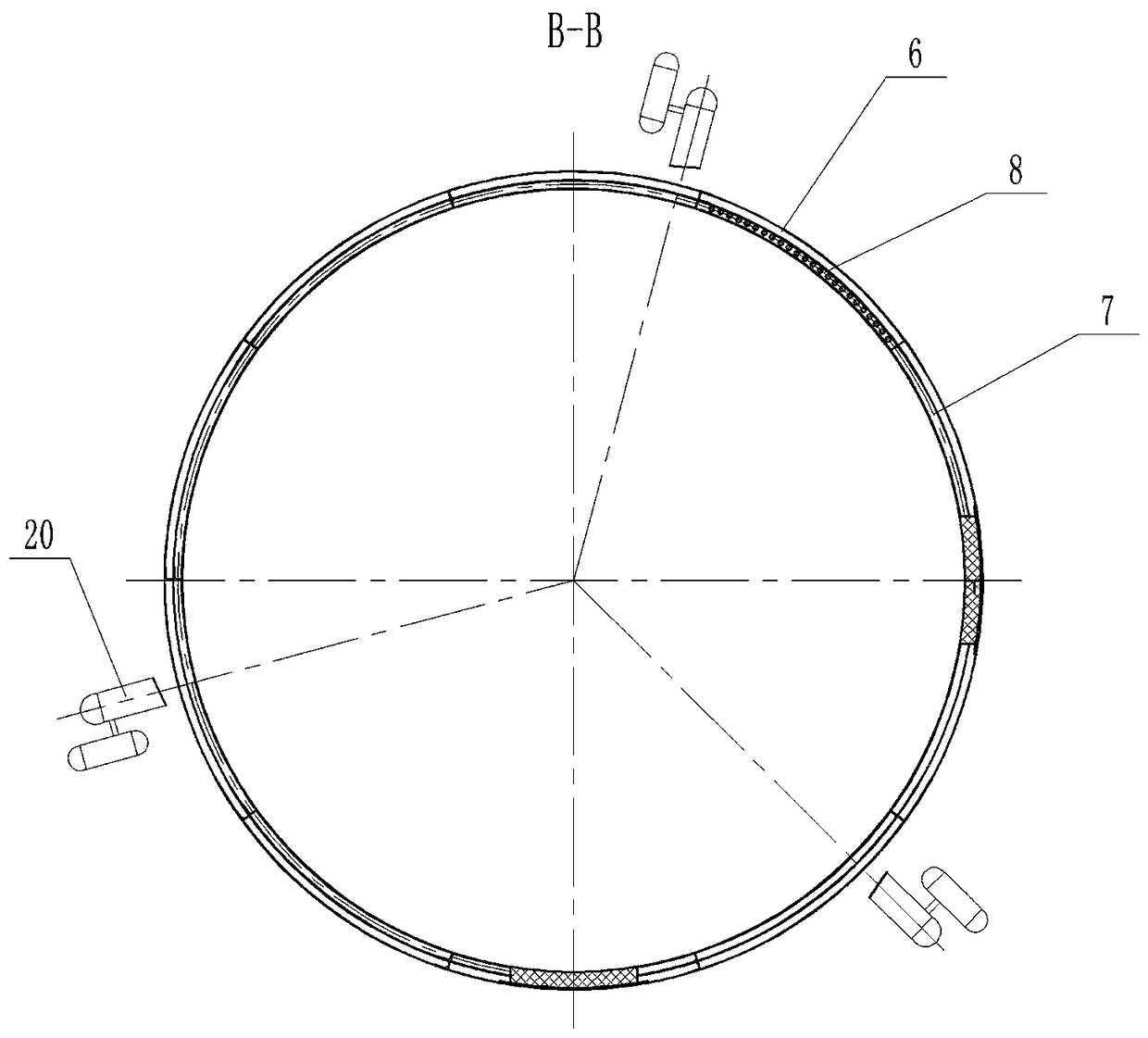

[0026] according to Figure 1-10 The specific structure of the present invention will be described in detail. The novel drying tower comprises an upper cylindrical shell 1 , and a conical shell 2 is arranged on the lower part of the cylindrical shell 1 . Among them, the top of the upper cylindrical cylinder 1 is provided with a hot air distributor 3 for continuously introducing hot air (temperature around 200°C) into the drying tower body; the middle part of the top hot air distributor 3 is provided with a The atomized liquid inlet 4 of the liquid atomized by the liquid atomizer. The bottom of the lower conical cylinder 2 is provided with a dry particle discharge port 15 for connecting with a dry powder delivery pipeline. In order to vibrate some of the dry particles attached to the inner wall 29 of the tower, three side wall vibrating air hammers 20 arranged at equal intervals along the same circumference are arranged on the outer side of the middle part of the cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com