Stirring machine

A mixer and agitator shaft technology, applied in the field of mixing machinery, can solve the problems of unsatisfactory mixing effect of the mixer and discontinuous conveying materials, etc., and achieve the effect of improving the mixing effect, reasonable structure and sufficient mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

[0019] The purpose of the present invention is to design a continuous mixer with simple structure, sufficient stirring and efficient conveying.

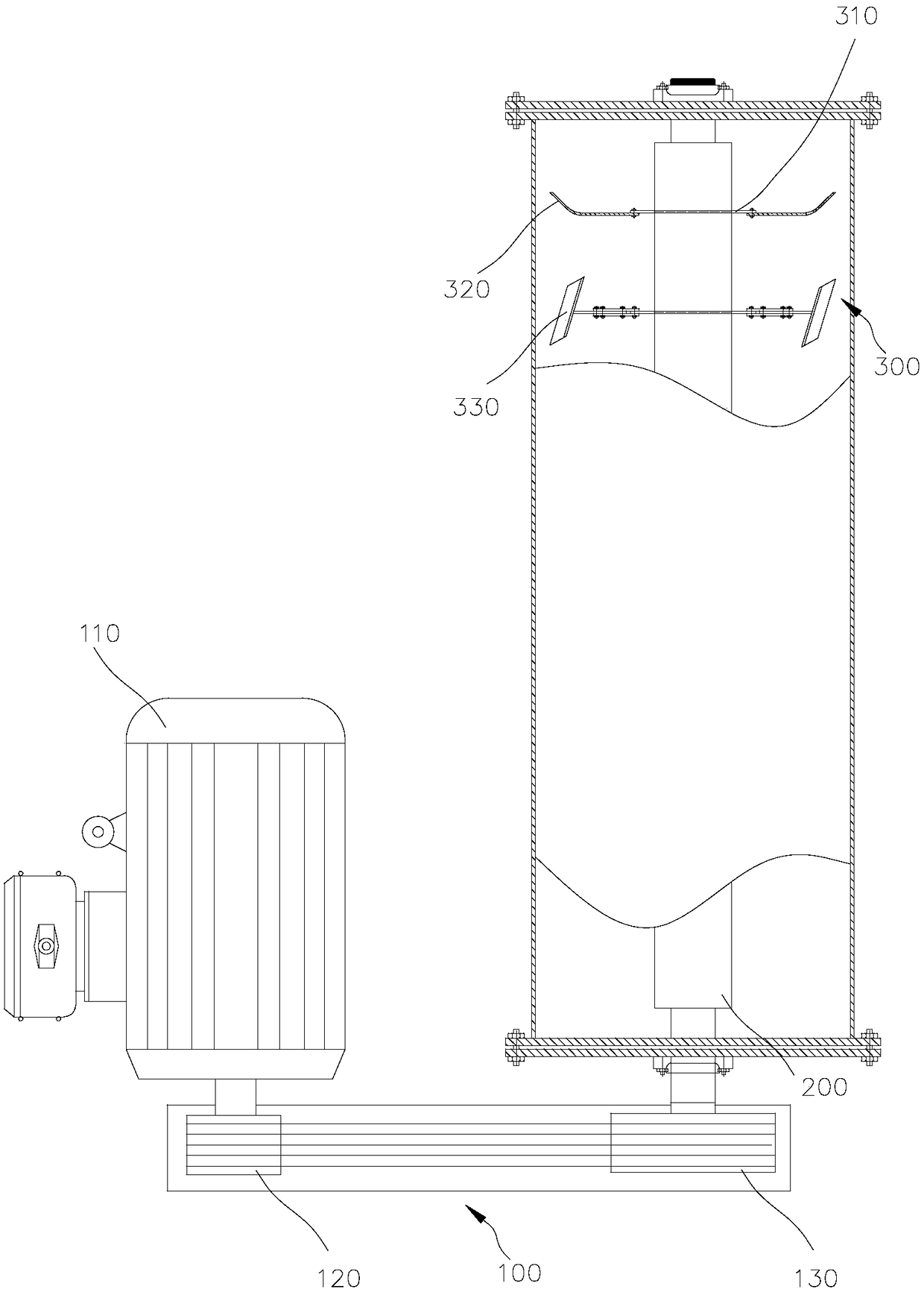

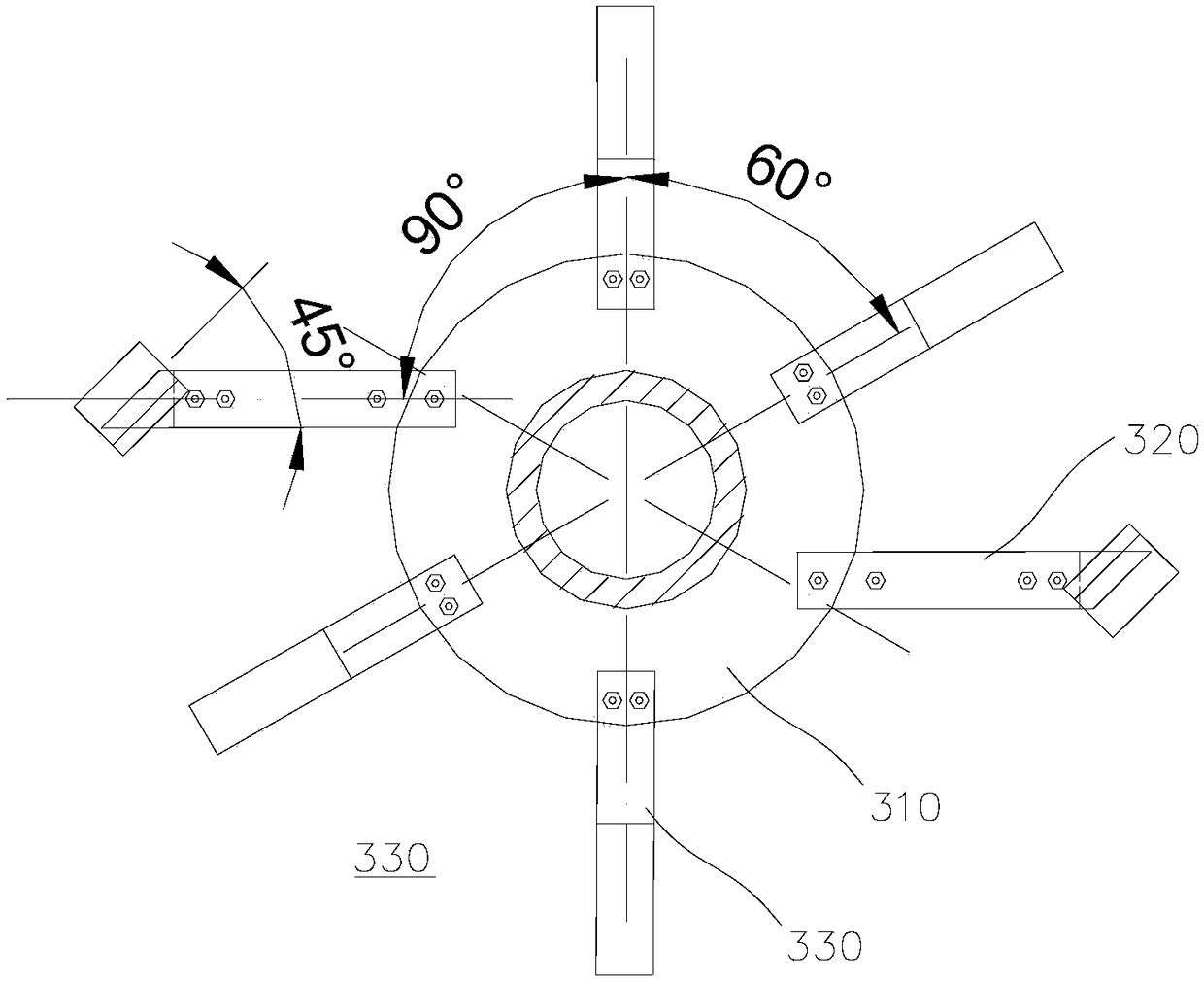

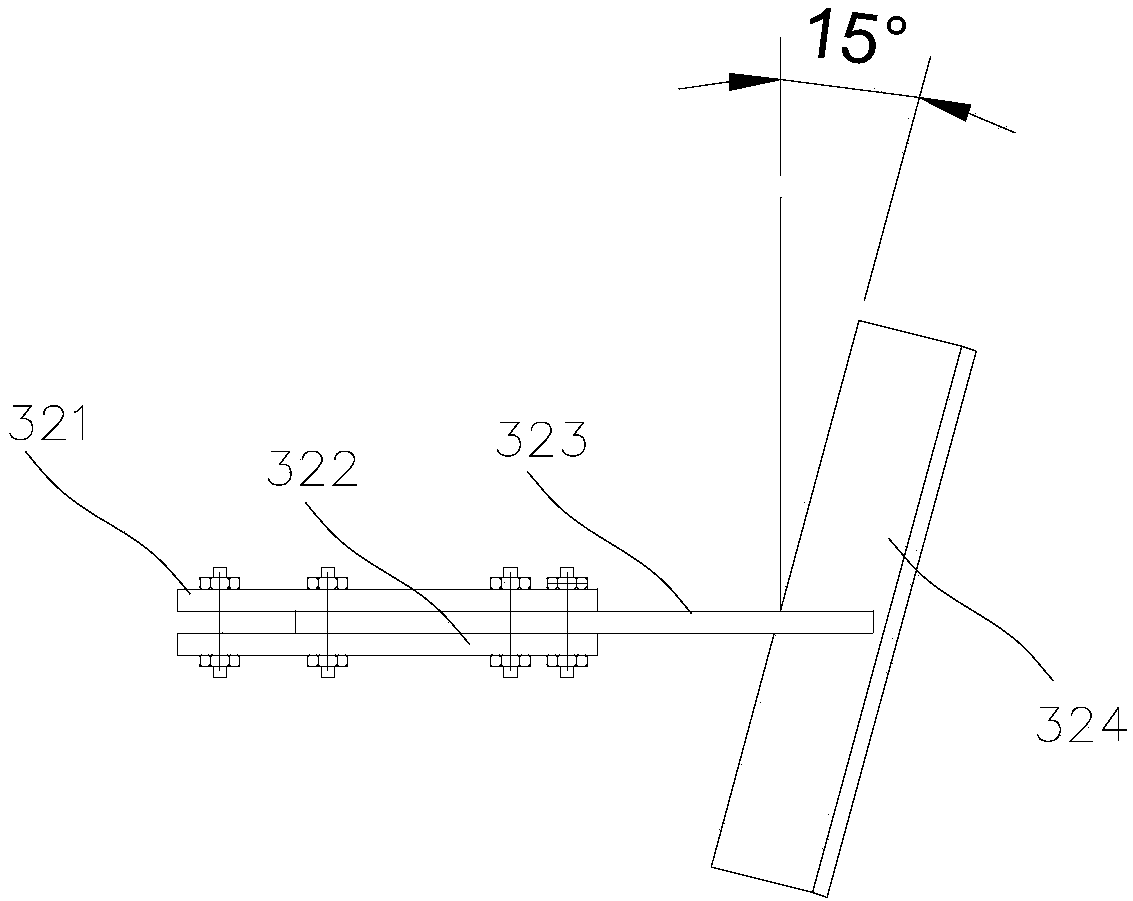

[0020] figure 1 It is a structural schematic diagram of a preferred embodiment of the mixer of the present invention, as figure 1 As shown, the mixer includes a power system 100 , a stirring shaft 200 driven by the power system 100 , and multiple sets of stirring blades 300 connected to the stirring shaft 200 . The stirring blade 300 includes a stirring paddle 310 , a rotary throwing blade 320 and a mixing blade 330 . The axial extension direction of the stirring shaft 200 is parallel to the direction of gravity.

[0021] The stirring paddle 310 is circular, sleeved in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com