Cleaning device for coating bucket

A technology for cleaning devices and paint buckets, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as inconvenience, poor cleaning effect, and inability to dispose of substances arbitrarily, so as to avoid splashing, Cleaning efficiency and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

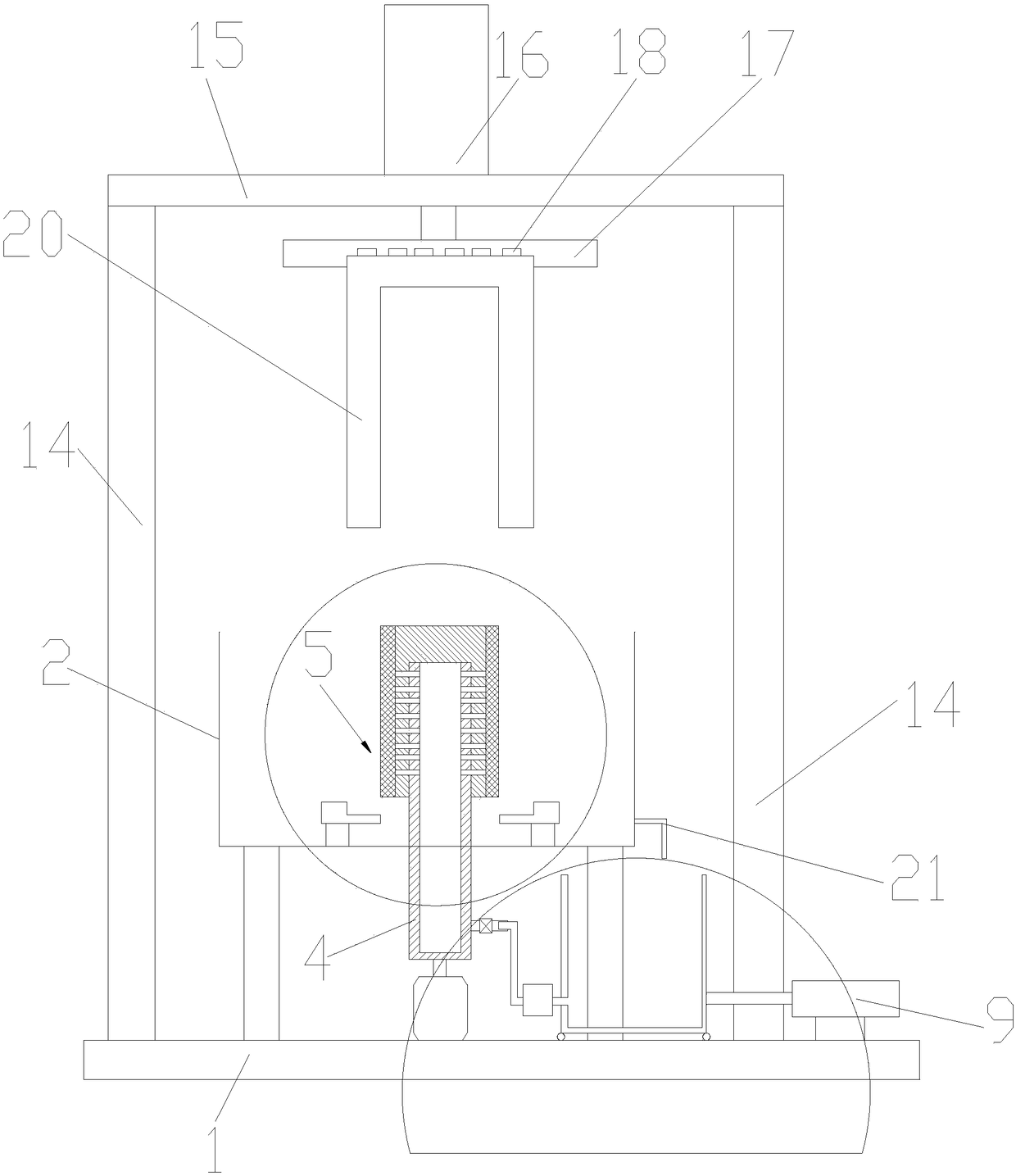

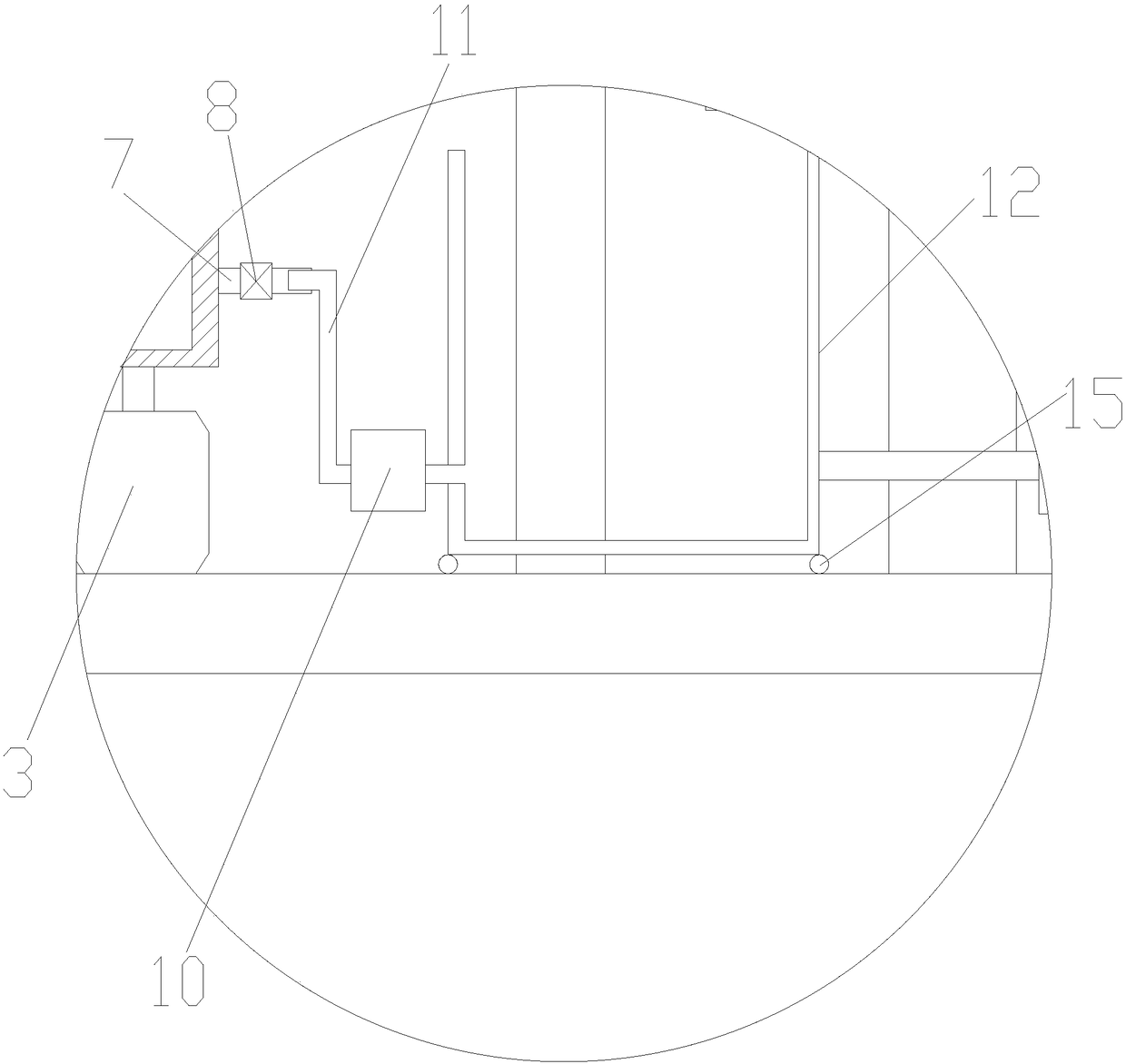

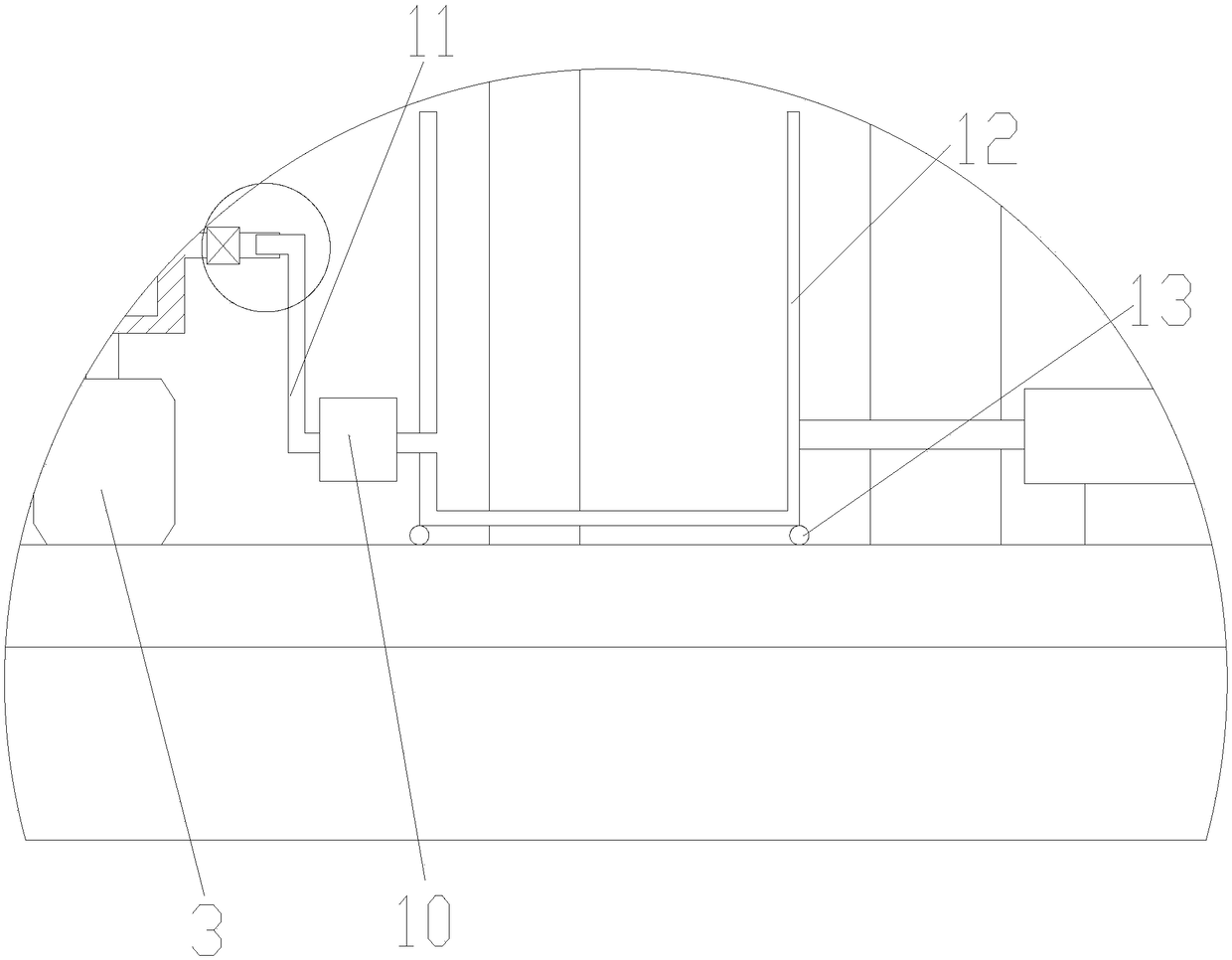

[0018] as attached Figure 1-4 The shown cleaning device for paint barrels according to the present invention includes a chassis 1, a cleaning frame 2, a drive motor 3, a hollow shaft 4, a brush 5, a spray pipe 6, a delivery pipe 7, and a shut-off valve 8 , telescopic cylinder 9, power pump 10, circulation pipeline 11, cleaning fluid tank 12, pulley 13, support 14, support plate 15, press down cylinder 16, bearing plate 17, electromagnetic sucker 18 and electromagnet 19; 1 is provided with a cleaning frame 2; the bottom of the cleaning frame 2 is provided with a drive motor 3 located on the chassis 1; the brush 5 is arranged in the cleaning frame 2, and it includes a brush rotating shaft 50 and a The bristles 51 outside the brush rotating shaft 50; the upper end of the rotating shaft of the drive motor 3 is provided with a hollow rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com