Pouring gate capable of adapting to superheat degree of tundish molten steel

A technology of tundish and superheat, which is applied in the direction of casting molten material container, metal processing equipment, casting equipment, etc., can solve the problems of no temperature fluctuation of molten steel in tundish, inability to adjust the temperature of molten steel, and fluctuation of superheat, so as to reduce the center Effects of segregation and porosity, promotion of equiaxed grain growth, and reduction of temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

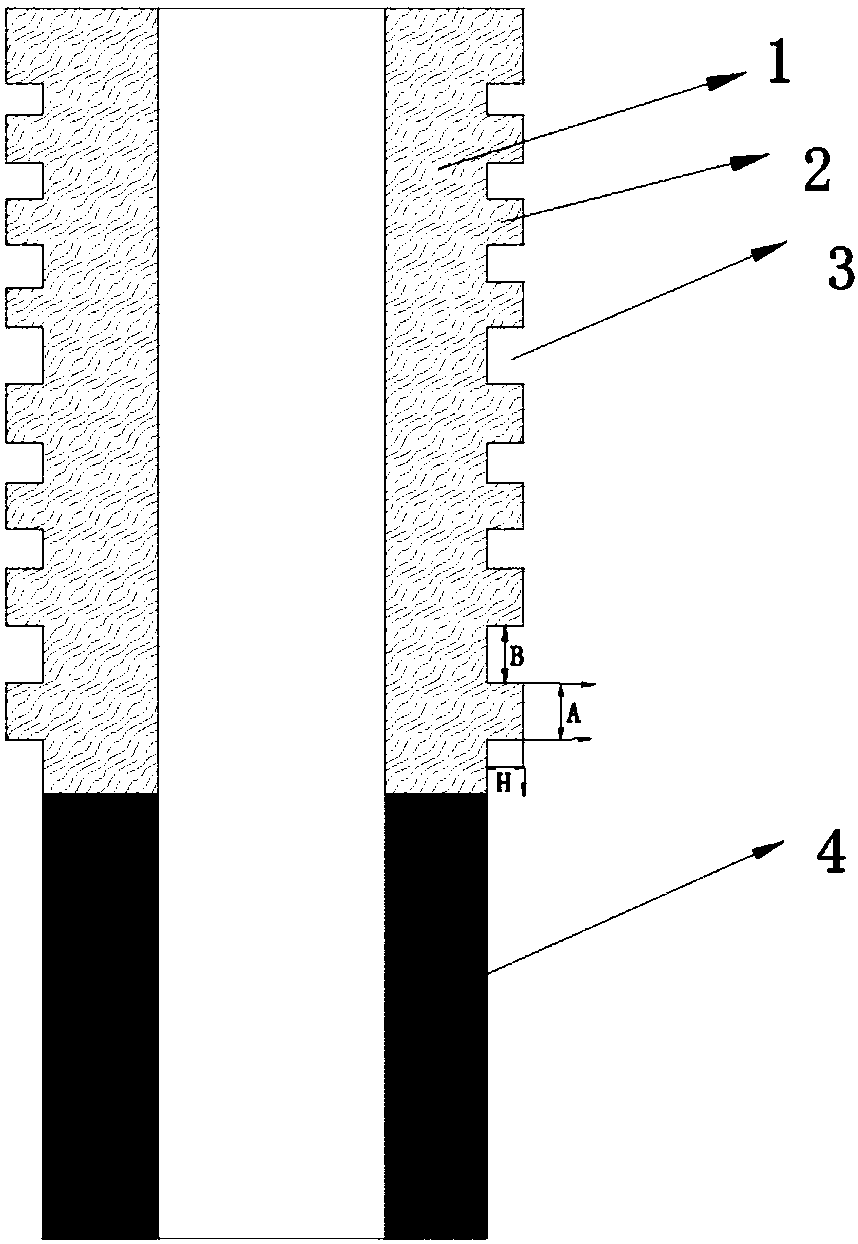

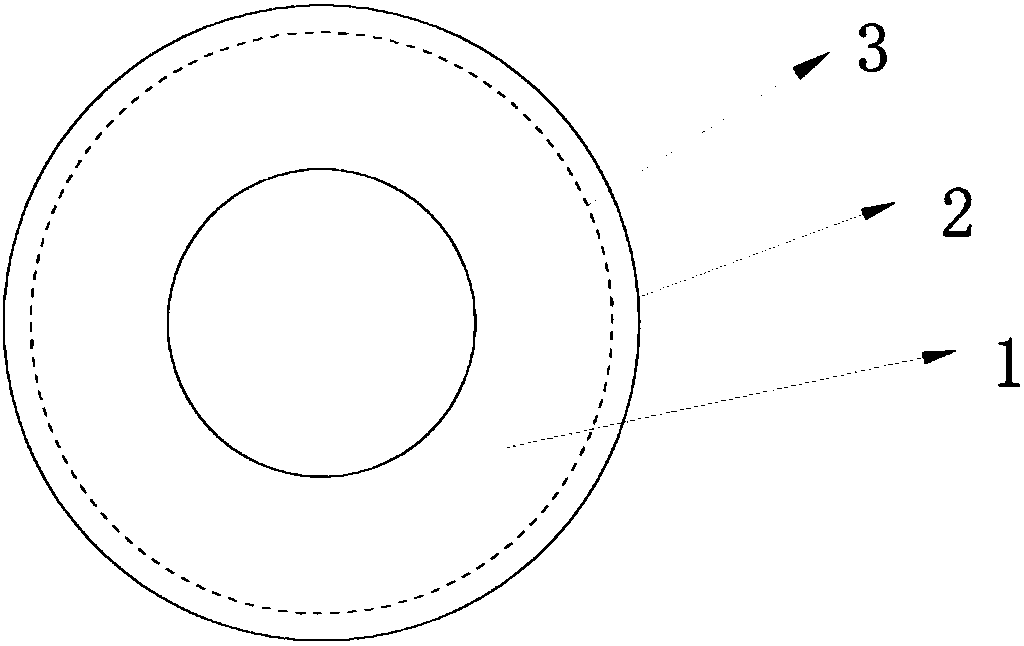

[0036] use as figure 1 , figure 2 In the nozzle body shown, 80 annular protrusions 2 are processed on the outer wall of the nozzle body 1, the height H of the annular protrusions 2 is 5 mm, the width A of the annular protrusions 2 is 5 mm, and there is an annular groove between every two annular protrusions 2 Groove 3, the depth H of the annular groove 3 is 5mm, and the width B of the annular groove 3 is 5mm. During the use of the nozzle, due to the double expansion of the cooling surface area, the heat dissipation speed of the nozzle to the air is doubled, which can solve the problem of intermediate The problem of high temperature of molten steel.

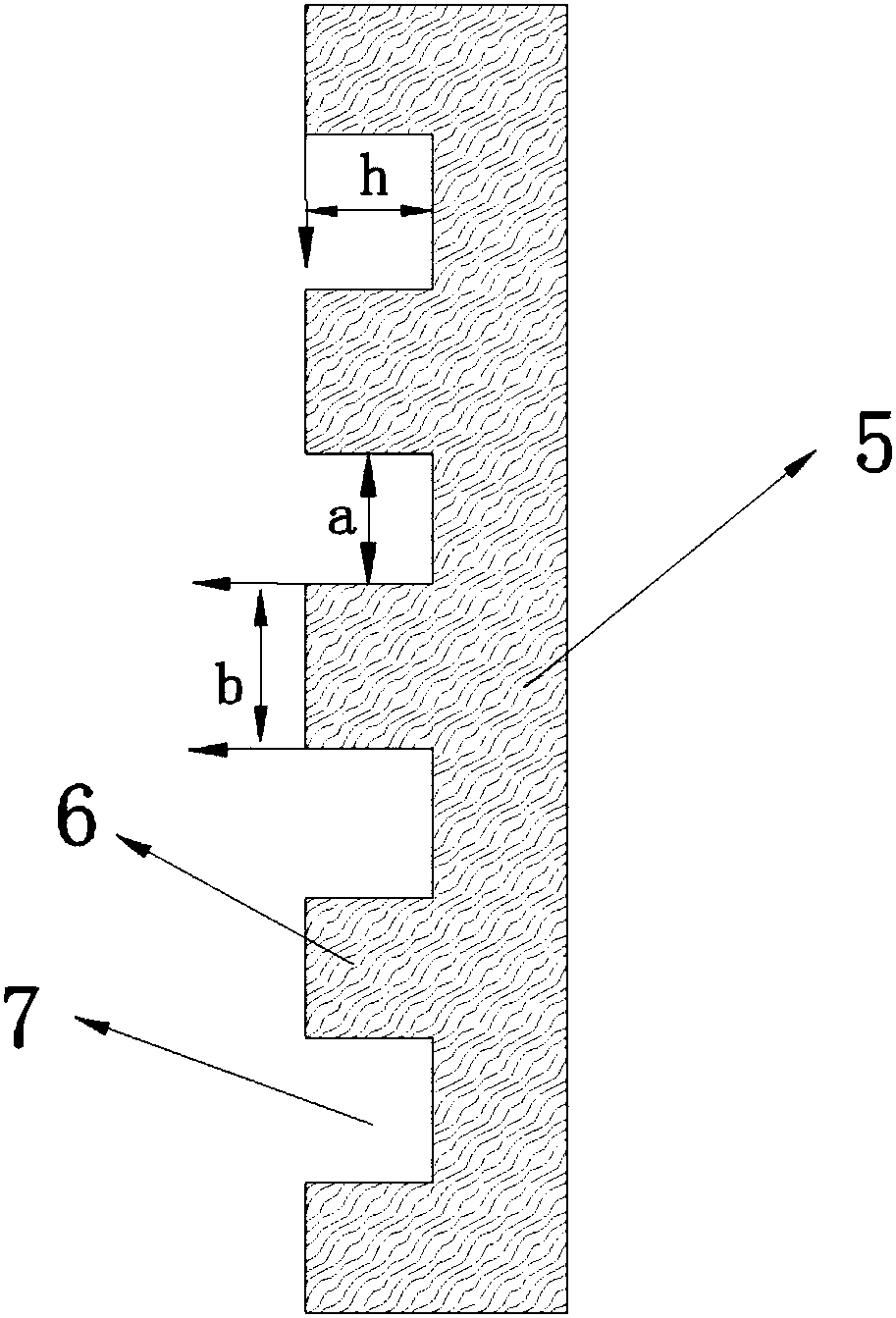

[0037] Use as shown in the figure image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the nozzle jacket 5, the length of the nozzle jacket 5 is 70% of the length of the nozzle body 1, and the material of the nozzle jacket 5 is asbestos board, and the asbestos content in the asbestos board is 70%, and the cross section o...

Embodiment 2

[0044] use as figure 1 , figure 2 In the nozzle body shown, 20 annular ridges 2 are processed on the outer wall of the nozzle body 1, the height H of the annular ridge 2 is 15 mm, the width A of the annular ridge 2 is 5 mm, and there is an annular groove between every two annular ridges 2 Groove 3, the depth H of the annular groove 3 is 15mm, and the width B of the annular groove 3 is 5mm. During the use of the nozzle, because the cooling surface area is enlarged by 3 times, the heat dissipation speed of the nozzle to the air is increased by 3 times, which can solve the problem of intermediate The problem of high temperature of molten steel.

[0045] Use as shown in the figure image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the nozzle jacket 5, the length of the nozzle jacket 5 is 10% of the length of the nozzle body 1. The material of the nozzle jacket 5 is asbestos board, and the asbestos content in the asbestos board is 85%. The cross section of the nozzle ja...

Embodiment 3

[0052] Others are the same as embodiment 1. The difference is:

[0053] use as figure 1 , figure 2 In the nozzle body shown, 40 annular protrusions 2 are processed on the outer wall of the nozzle body 1, the height H of the annular protrusions 2 is 10 mm, the width A of the annular protrusions 2 is 5 mm, and there is an annular groove between every two annular protrusions 2 Groove 3, the depth H of the annular groove 3 is 10mm, and the width B of the annular groove 3 is 5mm. During the use of the nozzle, because the cooling surface area is expanded by 2 times, the cooling speed of the nozzle to the air is increased by 2 times, which can solve the problem of intermediate The problem of high temperature of molten steel.

[0054] use as image 3 , Figure 4 , Figure 5 , Figure 6 As shown in the nozzle jacket 5, the length of the nozzle jacket 5 is 20% of the length of the nozzle body 1. The material of the nozzle jacket 5 is an asbestos board, and the asbestos content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com