Automatic retractable table trolley

A trolley and logistics technology, applied in the field of automated shrinkable logistics trolleys, to achieve the effects of improving work efficiency, facilitating unloading, and improving unloading work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

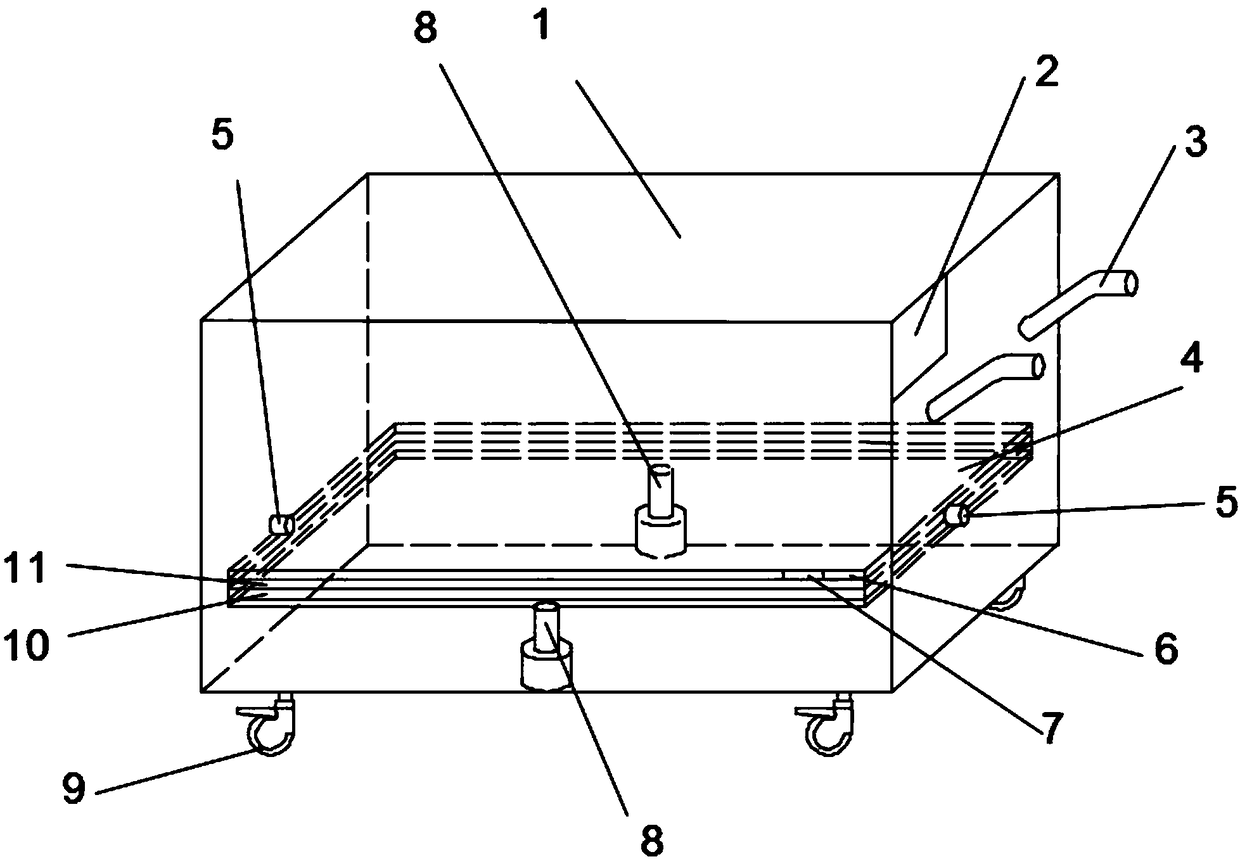

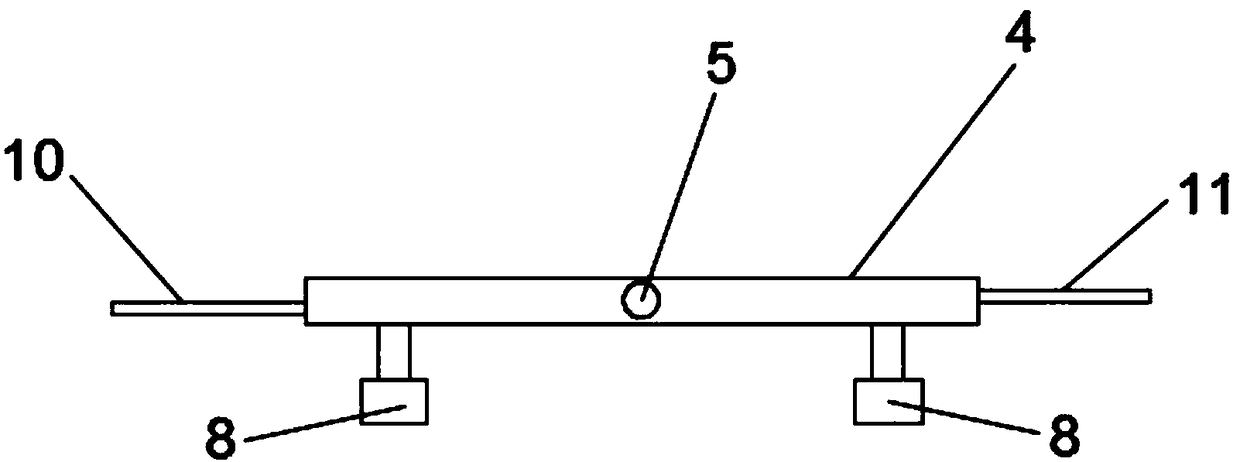

[0019] Such as Figures 1 to 2 As shown, the present embodiment provides an automatic shrinkable logistics trolley, including a cargo box 1, a push handle 3, a roller 9 and a storage board 4, the rollers 9 are arranged at four corners at the bottom of the cargo box 1, and the push handle 3 Located at the upper end of the rear part of the cargo box 1, the storage board 4 is arranged at the inner lower part of the cargo box 1, and the front and rear ends of the storage board 4 are respectively provided with a rotating shaft 5, and the rotating shaft 5 is connected to the inner wall of the front and rear walls of the cargo box 1. Rotationally connected, the left and right ends of the bottom of the storage board 4 are respectively provided with a hydraulic system, the hydraulic system includes a hydraulic cylinder 8, a hydraulic pump and a hydraulic valve, the hydraulic cylinder 8 is hingedly connected with the bottom of the storage board 4, and the storage A slide rail one and a ...

Embodiment 2

[0021] Such as Figures 1 to 2 As shown, the present embodiment has been further improved on the basis of Embodiment 1. Specifically, a PLC controller 7 is also provided in the storage board 4, and a control panel 2 is provided at the rear of the cargo box 1. The panel 2 is electrically connected to the PLC controller 7, and the PLC controller 7 is electrically connected to the hydraulic valve.

[0022] A gyro sensor 6 is also arranged in the storage board 4 , and the gyro sensor 6 is electrically connected to a PLC controller 7 .

Embodiment 3

[0024] Such as Figures 1 to 2 As shown, this embodiment is basically the same as Embodiment 2, the difference is that an angle sensor is also provided in the storage board 4 , and the angle sensor is electrically connected to the PLC controller 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com