High-efficiency packaging machine and packaging method for rotating bearing

A slewing bearing and packaging machine technology, which is applied in the direction of rotating and wrapping articles, can solve the problems of low packaging efficiency and poor packaging quality, and achieve the effect of good packaging quality, guaranteed accuracy and accurate centering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

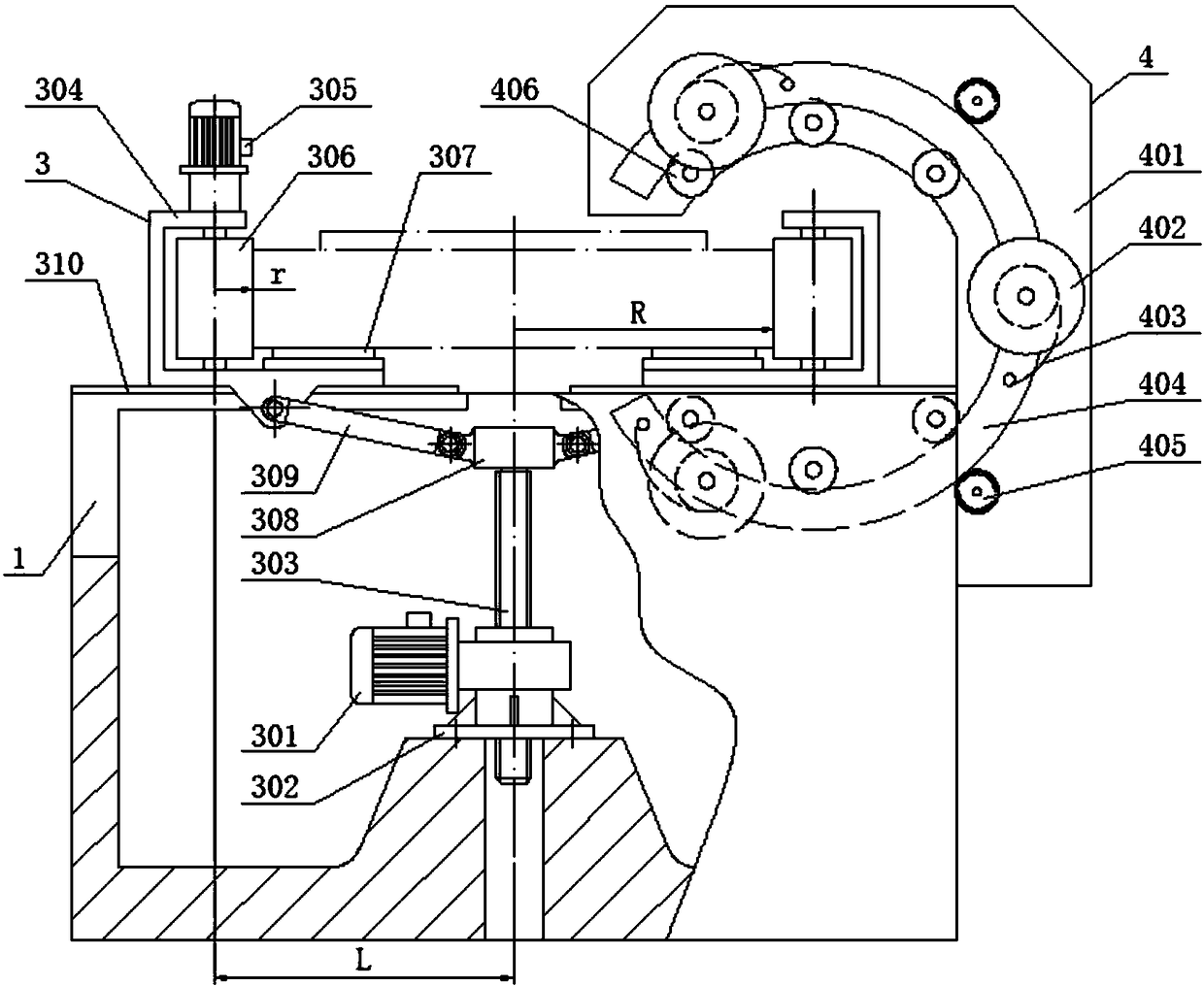

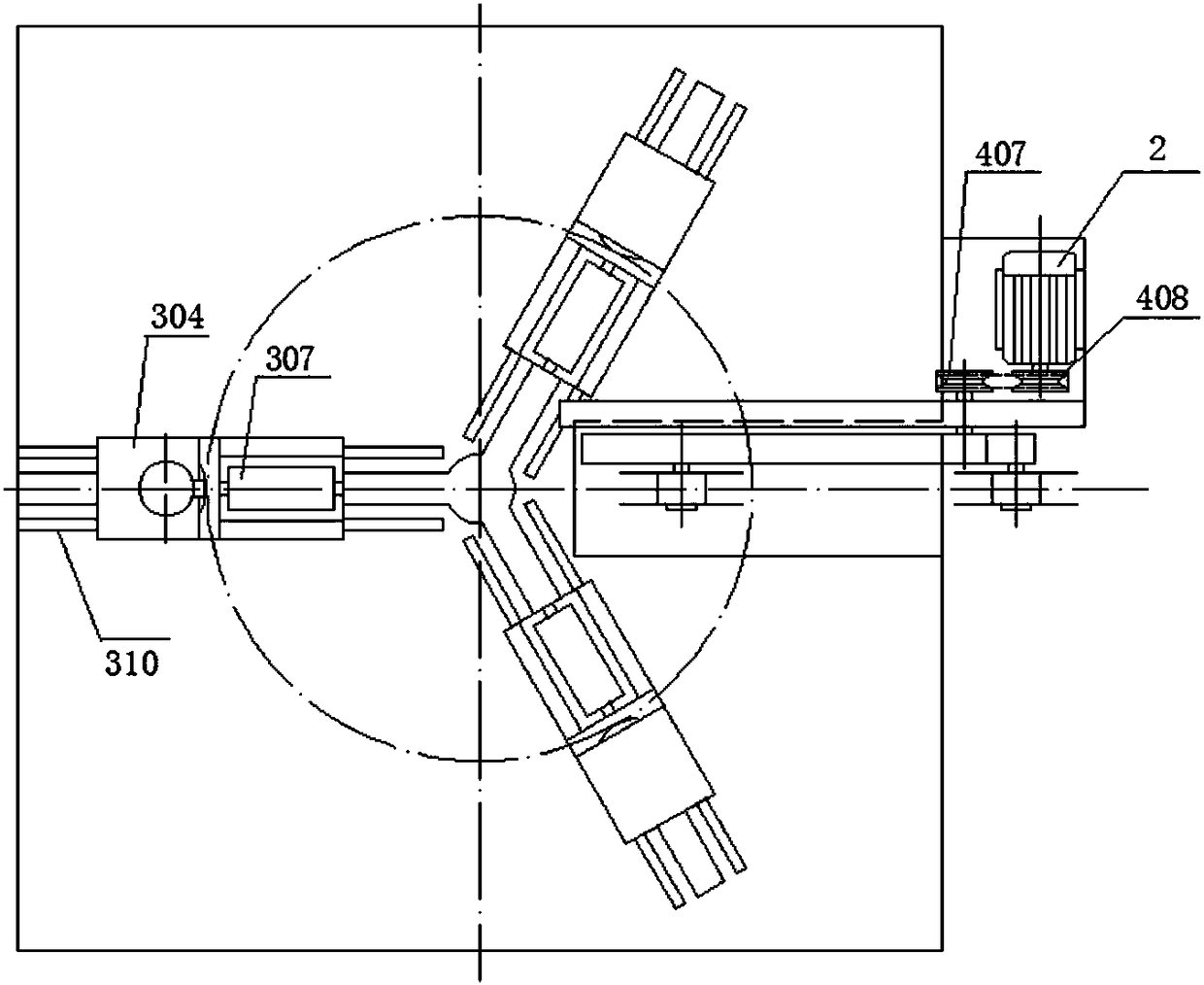

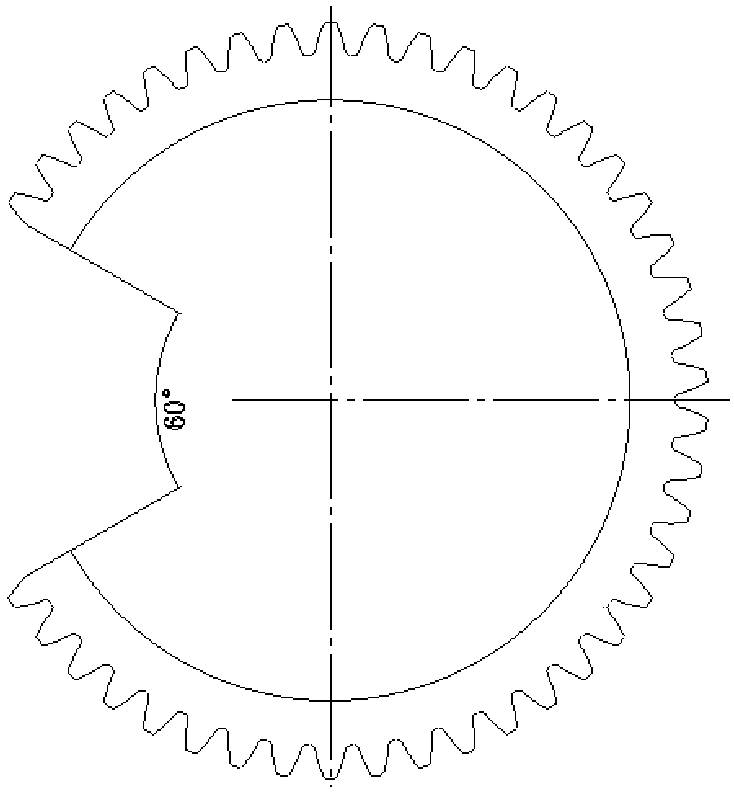

[0044] combine figure 1 , figure 2 , a packaging machine for high-efficiency slewing bearings in this embodiment includes a machine base 1, a centering and turning device 3 and a winding device 4, and the centering and turning device 3 and the winding device 4 are installed on the machine base 1, wherein: The centering and rotating device 3 includes a centering drive mechanism, a support seat 304 and a rotary drive wheel 306. The surface of the base 1 is provided with three linear guide rails 310 symmetrically distributed along the circumferential direction, and the centering drive mechanism drives the support seat 304 along a straight line. The guide rail 310 moves, and the center of the support base 304 is equipped with a rotary driving wheel 306 . The winding device 4 includes a support frame 401, a packing belt I-shaped wheel 402, a rotary ring gear 404 and a drive gear 405, wherein the support frame 401 is fixedly installed on the machine base 1, and the rotary ring gea...

Embodiment 2

[0046] A packaging machine for high-efficiency slewing bearings in this embodiment, its structure is basically the same as that of Embodiment 1, the difference mainly lies in: combining figure 1 , figure 2 , Figure 5 and Figure 6 ,, the centering drive mechanism includes a connecting nut 308, a connecting rod 309, a ball screw 303, a worm gear reducer 302 and a first motor 301, wherein the worm gear reducer 302 is fixed inside the base 1 And fixedly connected with the first motor 301, the worm gear center of the worm gear reducer 302 is equipped with a nut, the ball screw 303 passes through the nut and engages with it for transmission, and the shaft end of the ball screw 303 is fixedly installed with a connecting nut 308 , the connecting nut 308 is symmetrically rotatably connected with the three supporting seats 304 respectively through three connecting rods 309 . Specifically, a pair of angular contact ball bearings is installed at the center of the connecting nut 308,...

Embodiment 3

[0048] A packaging machine for high-efficiency slewing bearings in this embodiment, its structure is basically the same as that of Embodiment 2, and the main difference is that in this embodiment, the slewing drive wheel 306 is connected to the slewing drive system 305 above the support base 304. The drive system 305 is used to drive the slewing drive wheel 306 to rotate, and then drive the slewing bearing to rotate. The drive system 305 for turning includes a servo motor and a reducer. The inner side of the turning drive wheel 306 on the support base 304 is provided with supporting wheels 307, and the turning bearing to be packaged is supported by the supporting wheels 307. In this embodiment, the rotational speed ratio of the control rotary drive wheel 306 and the rotary ring gear 404 is n=B(L-R)(1-ε) / 2πR 2 , where B is the width of the packaging bag, L is the distance between the center of the rotary drive wheel 306 and the center of the slewing support to be packaged, R is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com