Transformer maintenance device

A technology for overhauling devices and transformers, which is applied in hoisting devices, switch devices, safety devices for lifting equipment, etc., can solve the problems that maintenance personnel are prone to fatigue, personnel safety threats, and waste of manpower, etc., to avoid static electricity and lightning damage, The effect of avoiding accidental falling from high altitude and reducing manpower waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

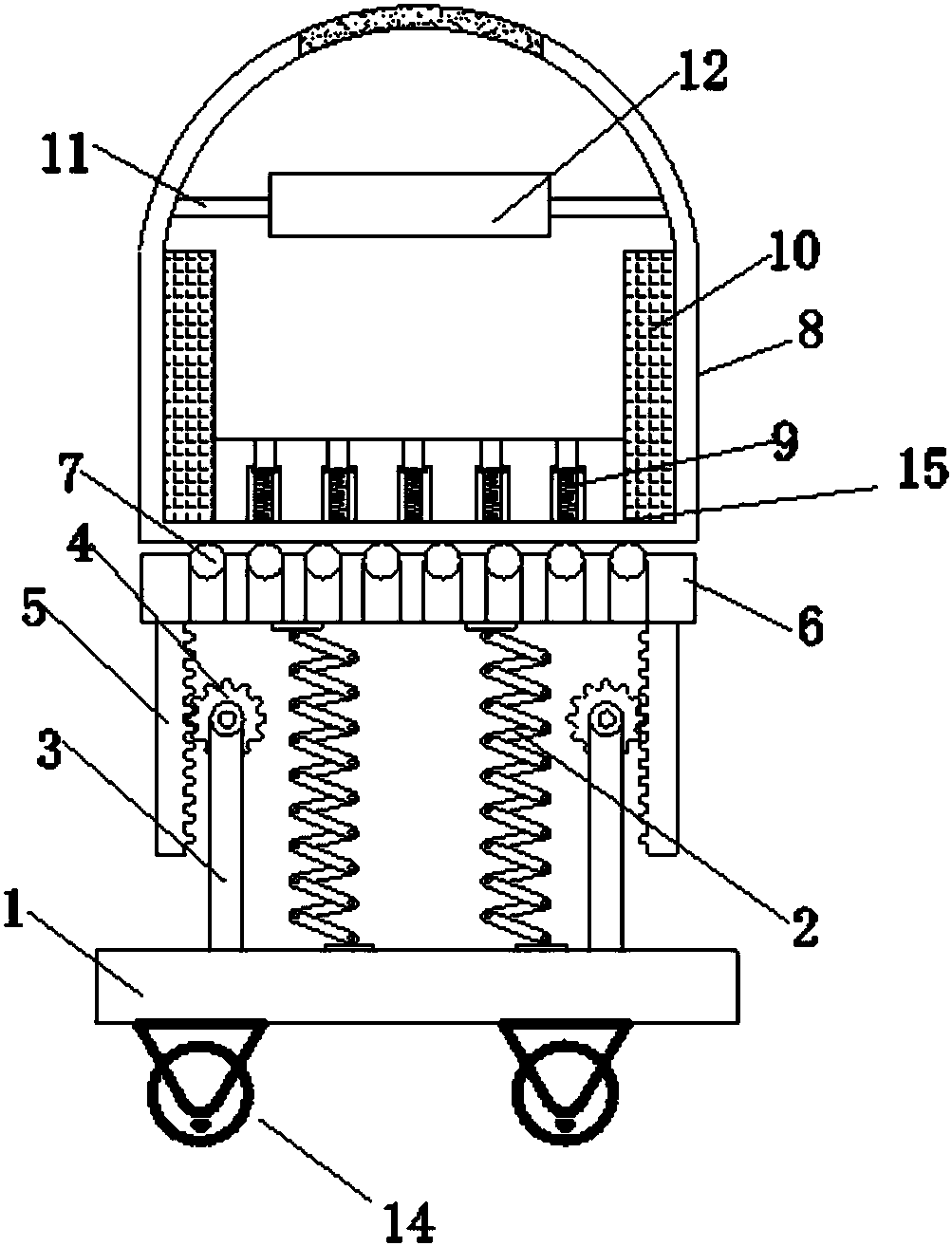

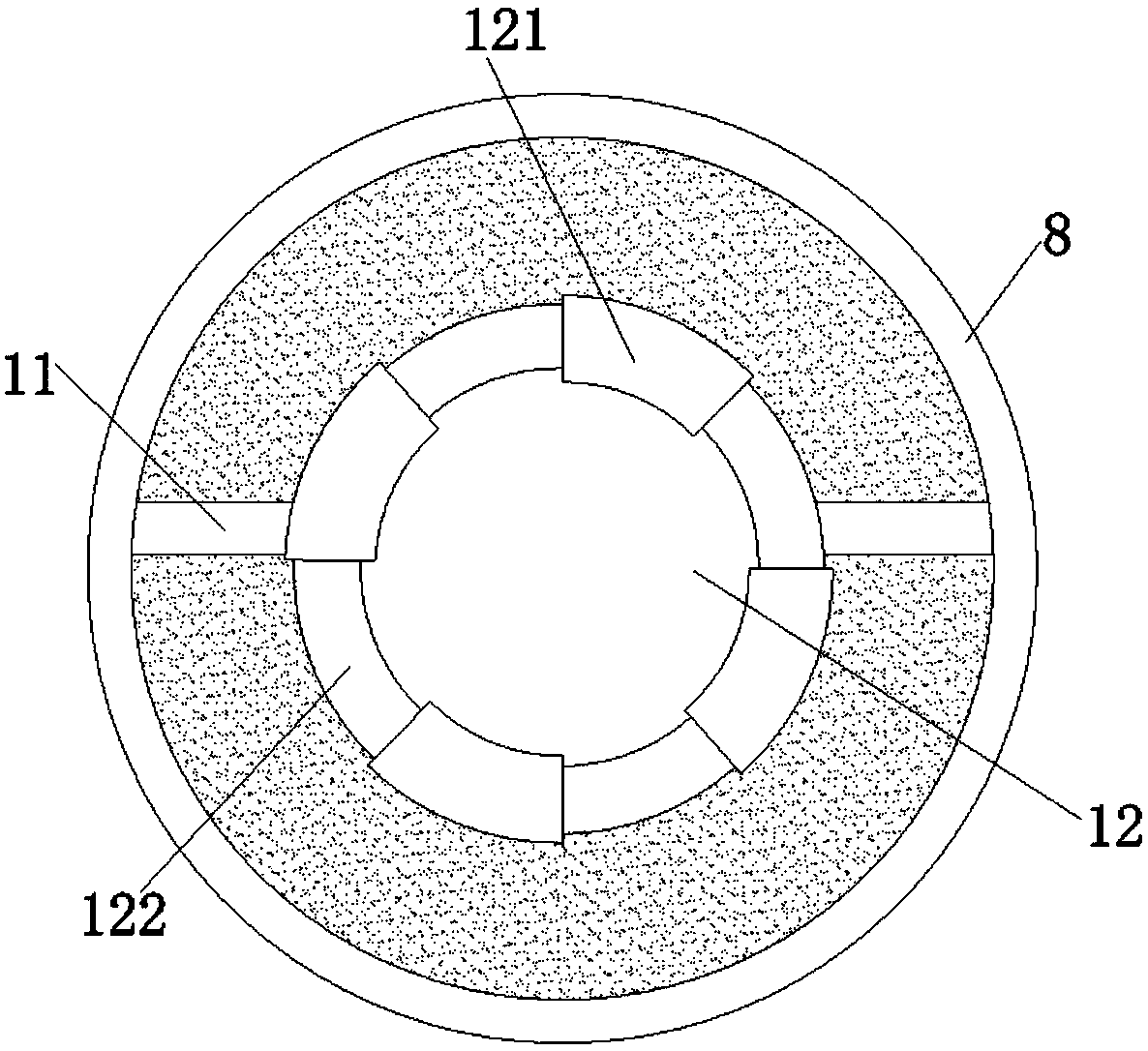

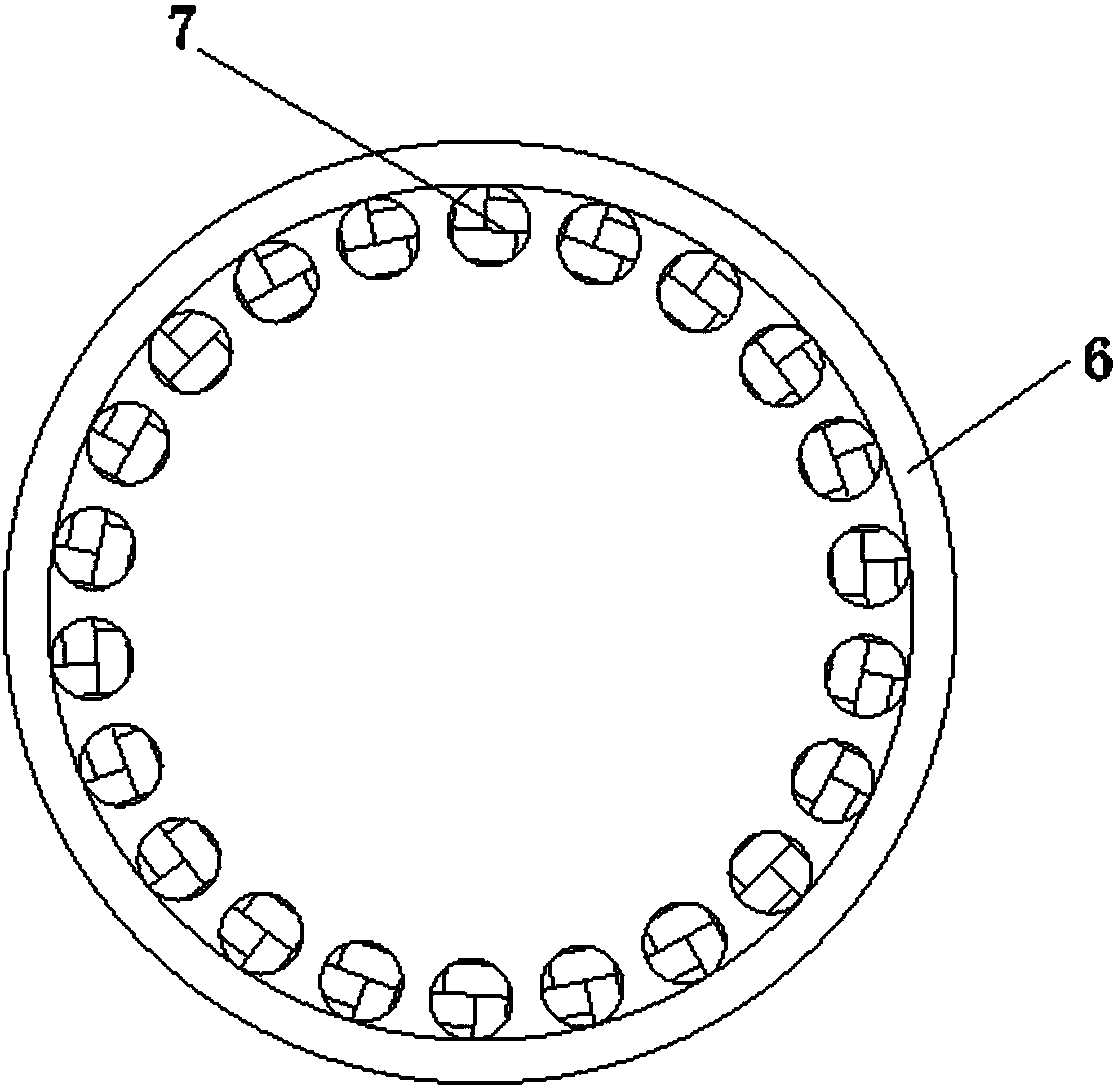

[0030] refer to Figure 1 to Figure 3 It is a preferred embodiment of the present invention. The present invention is a transformer maintenance device, including: 1. bottom plate, 2. folding rod, 3. support rod, 4. gear, 5. rack, 6. placing plate, 7. rotating shaft, 8. protective cover, 9. shock absorber Device, 10 protective layers, 11 connecting rods, 12 fixed rings, 121 fixed rods, 122 telescopic rods, 13 consoles, 14 wheels, 15 console bottom plates.

[0031] refer to Figure 1-3 , A rotating device is installed under the operating table 13, the lower part of the rotating device is fixedly connected with the lifting upper end, and the lower part of the lifting device is fixedly installed on the base plate 1. Through the lifting device, the operating platform 13 can move up and down in the vertical direction, so as to inspect and maintain transformers of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com