Rubber composition and processing method, and seal using same and production method

A technology of rubber composition and sealing strip, which is applied in the field of rubber, and can solve problems such as narrow molecular weight distribution of branched polyethylene, no new type of rubber disclosed, and inability to meet process requirements well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

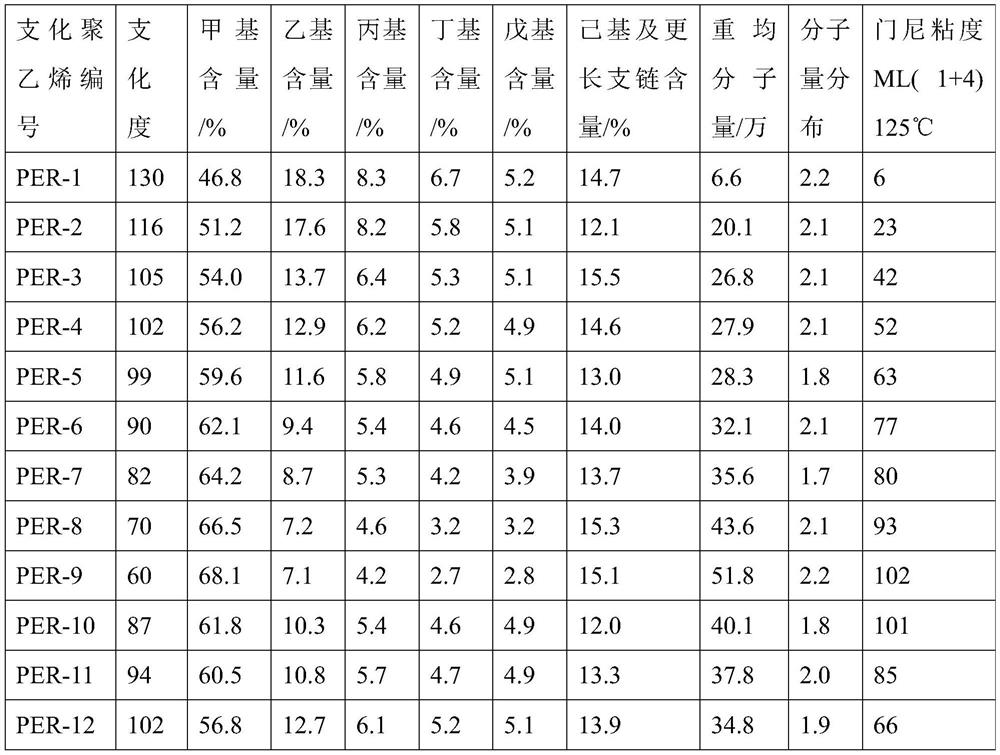

Method used

Image

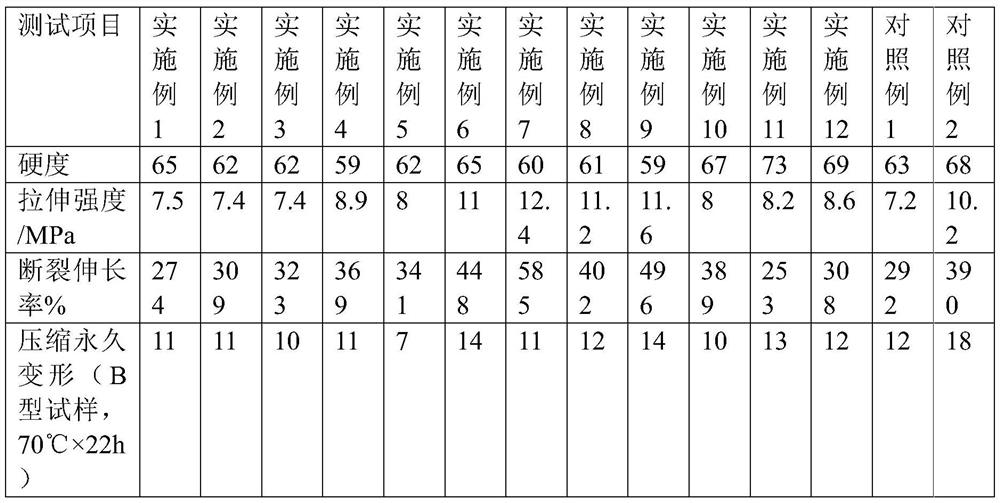

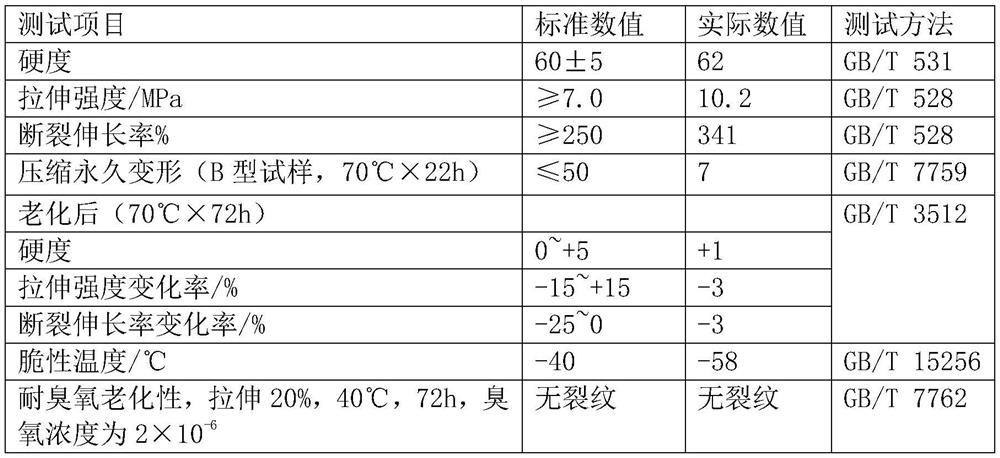

Examples

Embodiment 1

[0084] The number of branched polyethylene used is PER-9.

[0085] The processing steps of the test rubber composition are as follows:

[0086] (1) Mixing: Set the temperature of the internal mixer to 80°C, the rotor speed to 50 rpm, add 90 parts of EPDM rubber and 10 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 10 parts of zinc oxide , 1.5 parts of stearic acid, 5 parts of calcium oxide and 3 parts of PEG3400, mixed for 1 minute;

[0087] (2) Then add 120 parts of carbon black N550, 30 parts of calcium carbonate, and 90 parts of paraffin oil SUNPAR2280 into the rubber compound, and mix for 3 minutes;

[0088] (3) Finally, add 4 parts of cross-linking agent dicumyl peroxide (DCP), 1.5 parts of auxiliary cross-linking agent triallyl isocyanurate (TAIC) and 0.3 parts of sulfur, mix for 2 minutes and then remove the glue .

[0089] (4) Thinly pass the mixed rubber on an open mill with a roller temperature of 60°C to obtain a thin sheet with a t...

Embodiment 2

[0092] The number of branched polyethylene used is PER-8.

[0093] The processing steps of the test rubber composition are as follows:

[0094] (1) Mixing: Set the temperature of the internal mixer to 80°C, the rotor speed to 50 rpm, add 20 parts of EPDM rubber, 50 parts of EPDM rubber and 30 parts of branched polyethylene for pre-compression mixing 90 seconds; add 15 parts of zinc oxide, 2 parts of stearic acid, 10 parts of calcium oxide and 3 parts of PEG3400, and knead for 1 minute;

[0095] (2) Then add 120 parts of carbon black N550, 30 parts of calcium carbonate, and 80 parts of paraffin oil SUNPAR2280 into the rubber compound, and mix for 3 minutes;

[0096] (3) Finally, add 4 parts of cross-linking agent dicumyl peroxide (DCP), 1.5 parts of auxiliary cross-linking agent triallyl isocyanurate (TAIC) and 0.3 parts of sulfur, mix for 2 minutes and then remove the glue ;

[0097] (4) Thinly pass the mixed rubber on an open mill with a roller temperature of 60°C to obtain ...

Embodiment 3

[0100] The number of branched polyethylene used is PER-5.

[0101] The processing steps of the test rubber composition are as follows:

[0102] (1) Mixing: Set the temperature of the internal mixer to 80°C, the rotor speed to 50 rpm, add 50 parts of EPDM rubber and 50 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 5 parts of zinc oxide , 1.5 parts of stearic acid, 5 parts of calcium oxide and 3 parts of PEG3400, mixed for 1 minute;

[0103] (2) Then add 120 parts of carbon black N550, 30 parts of calcium carbonate, and 80 parts of paraffin oil SUNPAR2280 into the rubber compound, and mix for 3 minutes;

[0104] (3) Finally, add 4 parts of cross-linking agent dicumyl peroxide (DCP), 1.5 parts of auxiliary cross-linking agent triallyl isocyanurate (TAIC) and 0.3 parts of sulfur, mix for 2 minutes and then remove the glue ;

[0105] (4) Thinly pass the mixed rubber on an open mill with a roller temperature of 60°C to obtain a sheet with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com