Rubber composition and processing method, and rubber products using the same and production method

A rubber composition and rubber matrix technology, applied in the rubber field, can solve the problems of poor physical and mechanical properties, unable to further improve the aging resistance of products, unable to further improve the physical and mechanical properties and bonding properties of rubber materials, etc. performance, good compression set resistance, good ageing resistance and effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

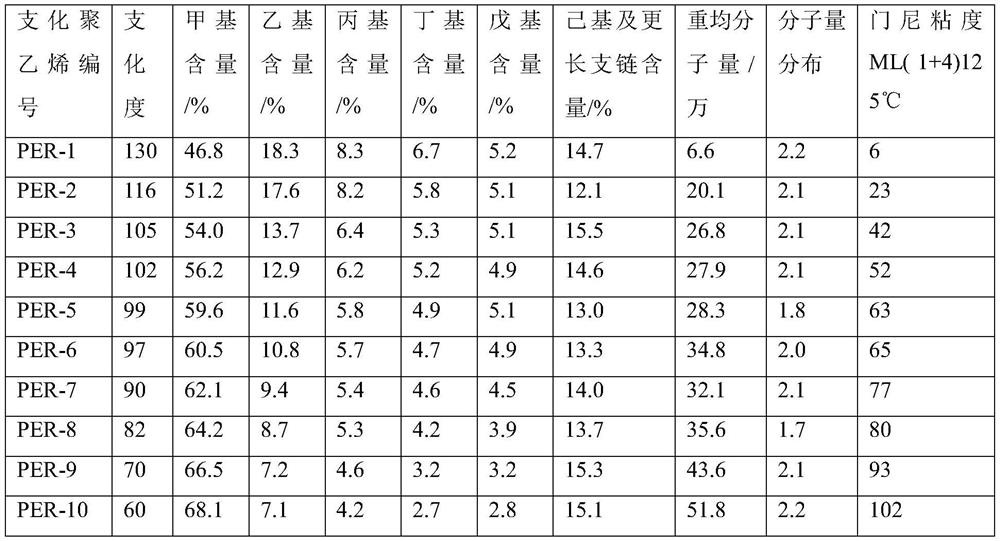

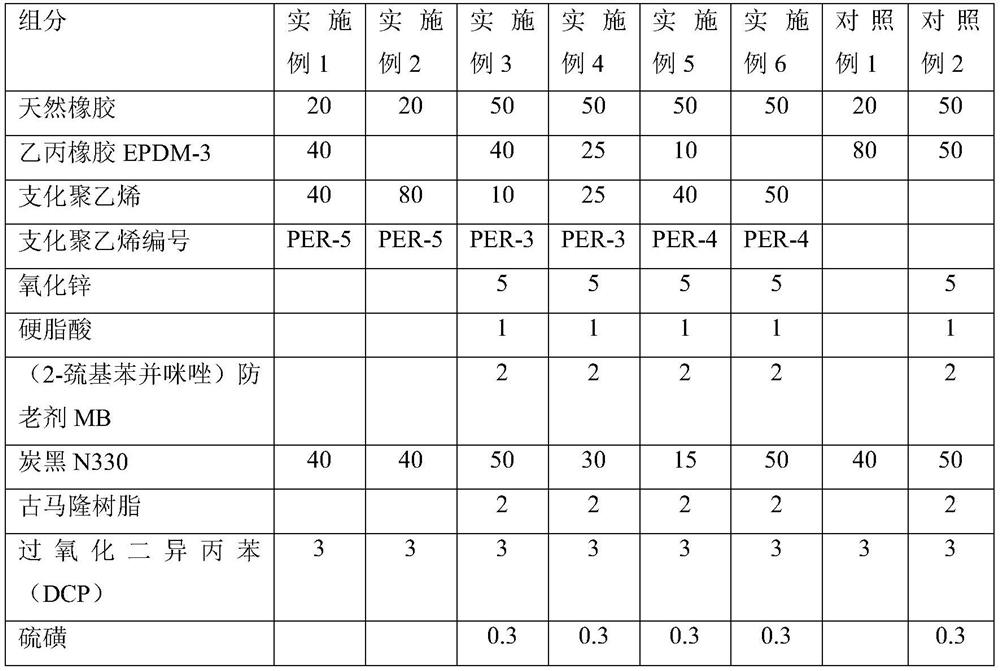

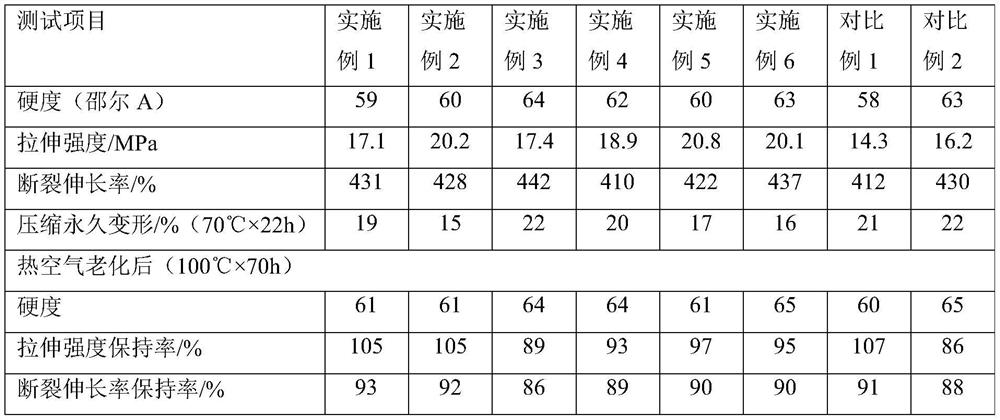

[0092] The specific embodiment of the rubber composition provided by the invention is:

[0093] A rubber composition is provided, comprising a rubber matrix, a reinforcing filler and a crosslinking agent, characterized in that, in parts by weight, each 100 parts of the rubber matrix contains more than 0 parts and no more than 99 parts of branched polymer Ethylene, 0-90 parts of ethylene-propylene rubber and 1-95 parts of isoprene-based elastomer, based on 100 parts by weight of rubber matrix, the rubber composition comprises 10-200 parts of reinforcing filler and 0.1-10 parts of cross-linking agent .

[0094] A preferred embodiment is that, in parts by weight, each 100 parts of the rubber matrix contains 10-95 parts of branched polyethylene, 0-60 parts of ethylene-propylene rubber and 5-90 parts of natural rubber; 100 parts by weight of rubber In terms of matrix, the rubber composition comprises 15-150 parts of reinforcing filler and 1-8 parts of cross-linking agent.

[0095...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com