An asymmetric pier and small radius curved bridge

An asymmetric and pier technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of large internal force and poor economic effect, and achieve the effect of optimizing lateral internal force, reducing the amount of reinforcement, and rich tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

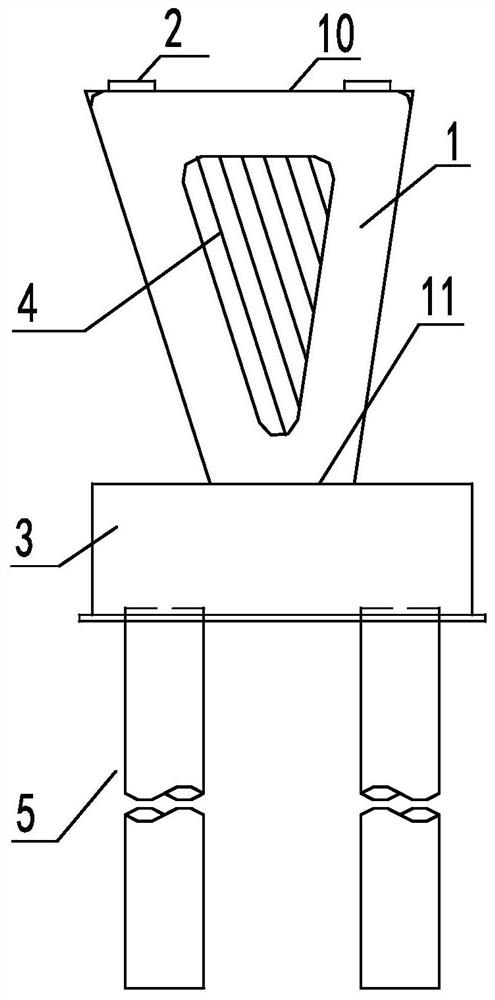

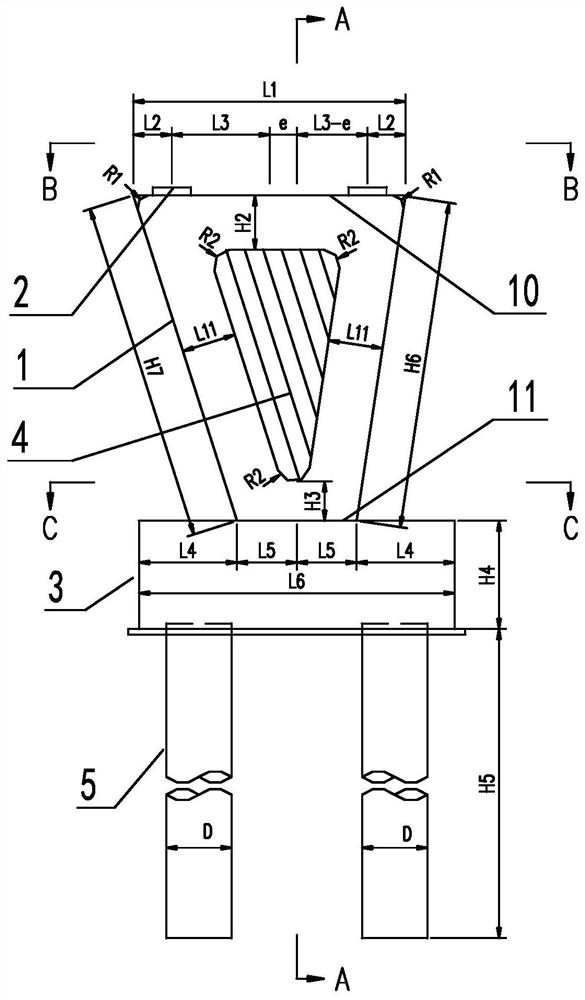

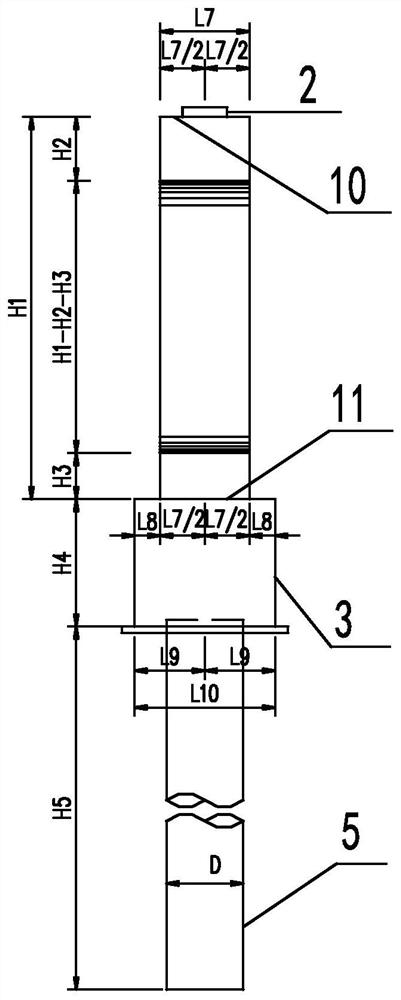

[0029] see figure 1 As shown, the embodiment of the present invention provides an asymmetric bridge pier, which is suitable for small-radius curved bridges, including a pier main body 1, and the pier main body 1 includes a pier top 10 and a pier bottom 11; Gradually decreases towards the bottom of the pier 11; the center line of the horizontal bridge of the pier bottom 11 is located between the center line of the horizontal bridge of the pier top 10 and the outer edge of the horizontal bridge of the pier top 10; the edges of the horizontal bridge of the pier bottom 11 are located at the top of the pier 10 bridges between the inner edge and the outer edge.

[0030] The principle of this scheme: the lateral bending moment of the bridge pier is transmitted by the load of the superstructure, and does not generate bending moment or very small bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com