Determination method of airfoil line of wind power generation blade

A wind power generation blade and wind power blade technology are applied in wind power generation, wind turbines, and wind turbines in the same direction as the wind to achieve the effect of improving the utilization rate of wind energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

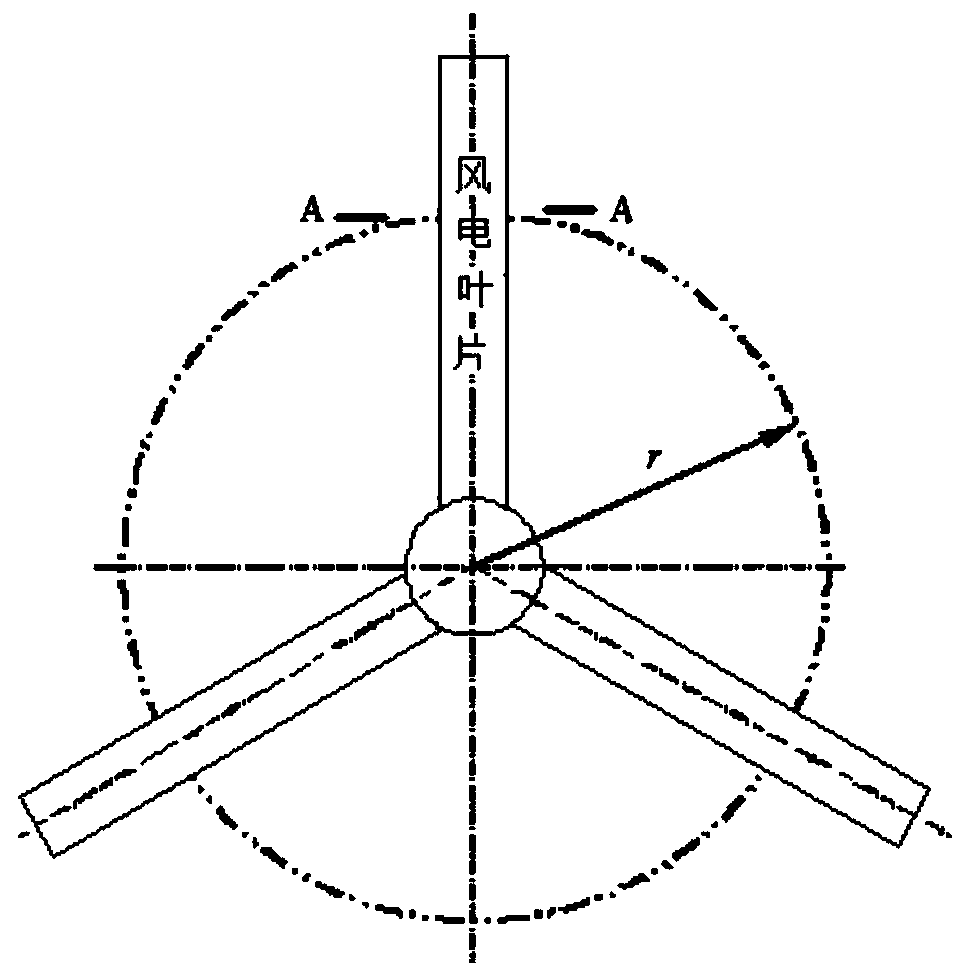

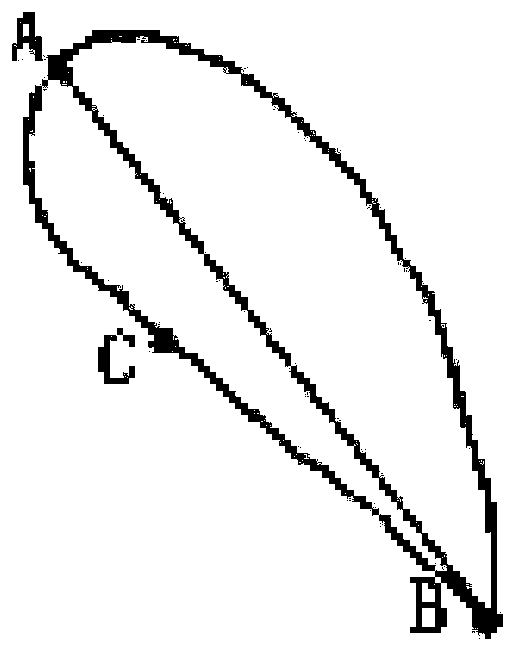

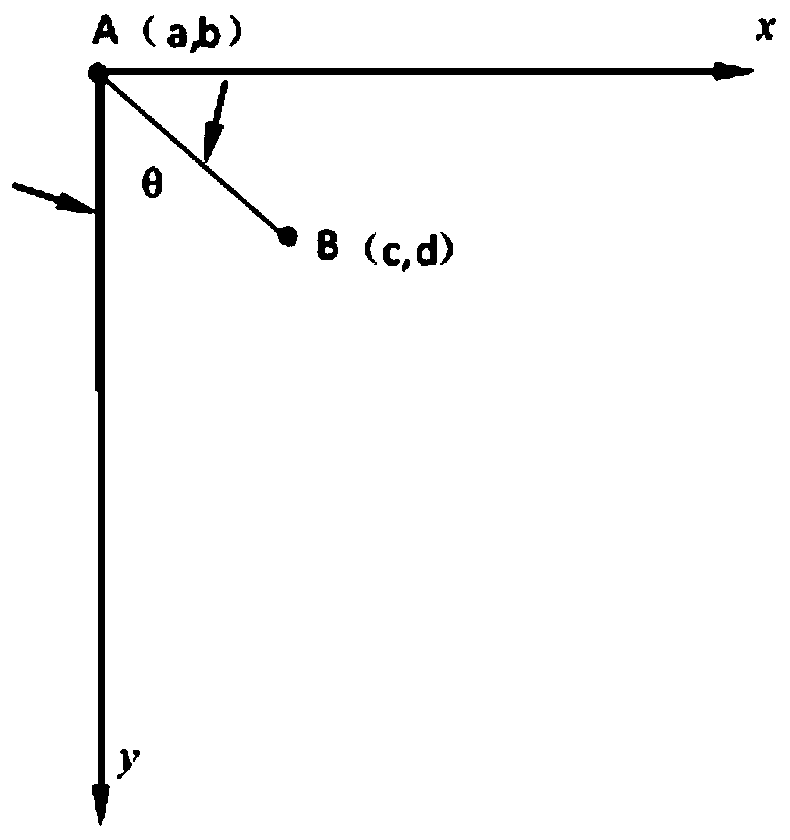

[0053] according to figure 1 , figure 2 Shown is a schematic diagram of a wind turbine. First build as image 3 In the Cartesian coordinate system of the airfoil of the wind power blade shown, it is assumed that the chord length AB of the airfoil on the blade whose distance from the rotation axis of the wind rotor is r is r, and the torsion angle is θ. The origin A slides to point B, if there is a curve Γ between points A and B, so that the time for the air mass to slide from point A to point B is the shortest, it means that the number of air masses sliding across the curve Γ within a certain period of time is large, That is, during this time, there are more air masses interacting with the curve Γ, so that the curve can obtain more energy from the air mass. Therefore, if the curve Γ is used as the airfoil line of the blade, The blade will be able to convert the kinetic energy of the air mass into the mechanical energy of the wind power blade;

[0054] 1) Determine the bla...

Embodiment 2

[0065] According to the traditional design method, the chord length of the blade airfoil at a certain radius of the wind rotor is l=2.38, and the twist angle θ=10.47o. Establish image 3 Shown coordinate system, wherein OB=l, is airfoil chord length, then the coordinate of point B is

[0066]

[0067] According to formula (19),

[0068]

[0069] Take D=1.17, substitute into formula (18), get airfoil line equation

[0070]

[0071] The airfoil line designed according to formula (20) (such as Figure 4 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com