Layered fan wind wheel and wind turbine adopting layered fan wind wheel

A layered, wind wheel technology, applied in the field of wind energy utilization, wind machinery and wind power generation, can solve the problems of low wind energy utilization efficiency at the blade root, high start-up wind speed, and decreased wind resistance of the fan, so as to reduce weight and improve Effect of power generation efficiency and length increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

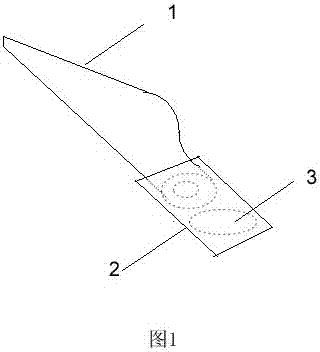

[0067] Such as figure 1 as shown, figure 1 It is a schematic diagram of the structure principle of the horizontal axis fan blade of the present invention; an extension device 2 is installed at the root of the blade 1, and one or more closed space devices 3 are installed inside the extension device 2, and the closed space device 3 is a rubber sealed bag or plastic sealed bag full of helium, which can replace or partially replace the original inner filler such as balsa wood or foam material or ribs. When the blade is running, the rubber sealing bag or plastic sealing bag generates upward buoyancy in the extension device 2, and holds the inner wall of the extension device 2, which can offset a part of the gravity of the extension device 2, reduce the overall weight of the blade, and reduce the motion generated Vibration, improve power generation efficiency. The shape of the extension device 2 matches the root of the blade 1 .

Embodiment 2

[0069] Such as figure 2 --9, figure 2 It is a schematic diagram of the front view of the structure principle of the horizontal axis fan rotor of the present invention; image 3 It is a schematic diagram of the left view of the structure principle of the horizontal axis fan rotor of the present invention; the top view is common knowledge and is omitted. In this embodiment, an extension device 2 is installed outside the hub 7 of the horizontal axis wind wheel. The extension device 2 is ellipsoidal or semi-ellipsoidal or any shape that can help wind blow to the blade. 1 or / and 4 are installed on the extension device 2 . One or more closed space devices 3 are installed inside the extension device 2, and the closed space devices 3 are rubber sealed bags or plastic sealed bags filled with helium, which can replace or partially replace the original internal filling Such as balsa wood or foam or ribs.

[0070] Figure 4 It is a front view schematic diagram of another structural...

Embodiment 3

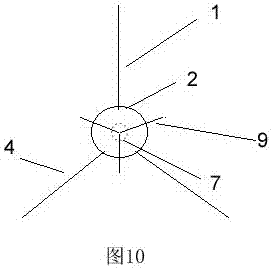

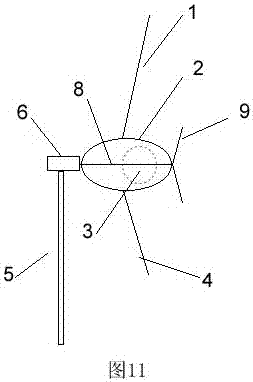

[0074] Such as Figure 10 , 11 as shown, Figure 10 It is a front view schematic diagram of another structural principle of the horizontal axis fan rotor of the present invention; Figure 11 It is a schematic diagram of the left view of another structural principle of the horizontal axis fan rotor of the present invention; the top view is common knowledge and is omitted.

[0075] In this embodiment, the extension device 2 can replace the role of the hub, the extension device 2 is an ellipsoidal or part ellipsoidal or spherical or part spherical structure; the extension device 2 is installed on the fan shaft 8, on the In the structure of the extension device 2, a group of long fan blades 1 or 4 are installed, and a group of short fan blades 9 are installed in front of the extension device 2.

[0076] In this embodiment, 3 short fan blades are installed, and the length of the short fan blade 9 is less than the long fan blade 1 or 4; the small wind wheel can reduce the rated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com