Steam condensation water integrated recovering device

A steam condensate water recovery device technology, applied in the direction of steam generation, supplementary water supply, preheating, etc., can solve problems such as pressure loss, cavitation of high-temperature condensate pumps, etc., to solve pressure loss, improve steam heat utilization efficiency, and improve energy The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

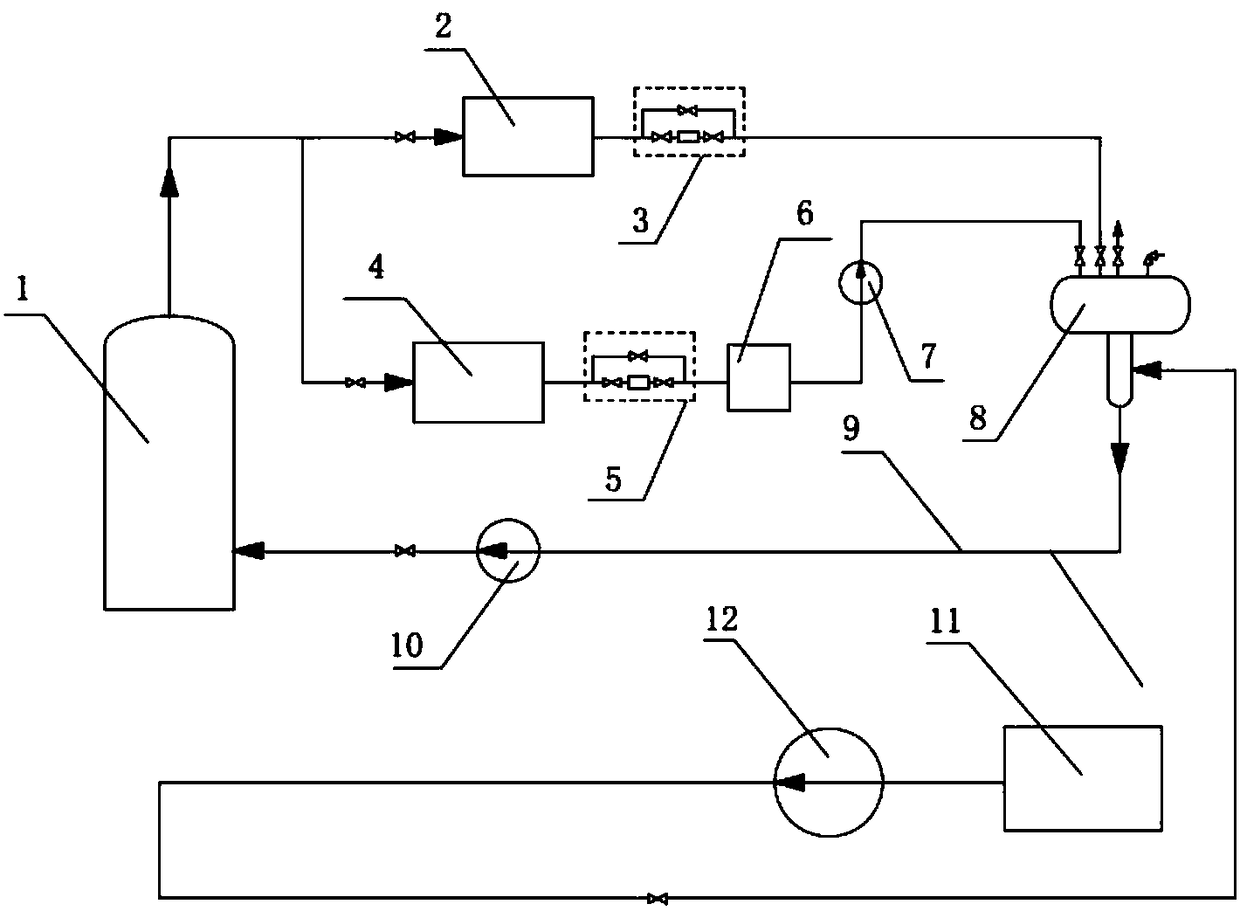

[0021] Such as figure 1 Shown is a schematic flow chart of a steam condensed water integrated recovery device of the present invention.

[0022] Below by specific embodiment, in conjunction with its accompanying drawing, this scheme is elaborated:

[0023] An integrated recovery device for steam condensed water, in which the steam generated by boiler 1 is sent to No. 1 heating equipment 2, No. 1 steam trap group 3, No. The condensed water produced by No. 6 thermal equipment, No. 2 thermal equipment 4, No. 2 drain valve group 5, and No. 3 thermal equipment 6 is pressurized by the pressure regulating pump 7, and drained with No. 1 thermal equipment 2 and No. 1. The condensed water generated by the valve group 3 is sent to the buffer tank 8, and then sent to the boiler 1 through the high-temperature condensed water pump 10; the boiler feed water in the water tank 11 is sent to the buffer tank 8 through the feed water pump 12.

[0024] The No. 1 steam trap group 3 is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com