Engine cylinder cover structure

A technology of engine cylinder head and cylinder head, which is applied in the direction of engine components, machines/engines, cylinder heads, etc., can solve the problems of pressure loss, increase in the number of parts, and increase in the number of parts, so as to solve pressure loss, reduce costs, and reduce parts Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

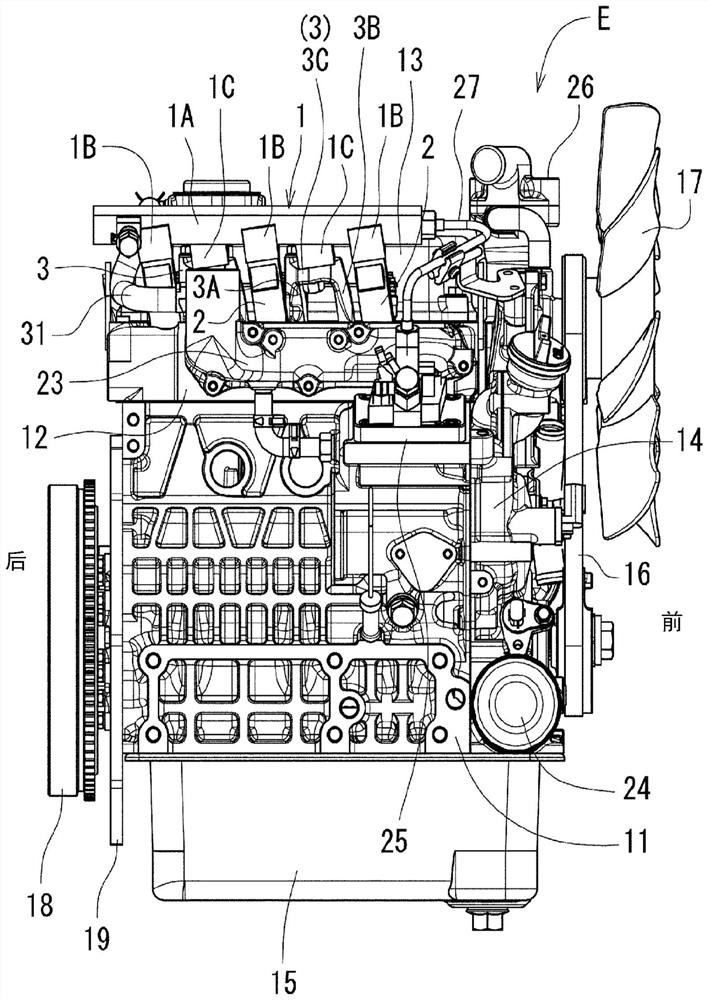

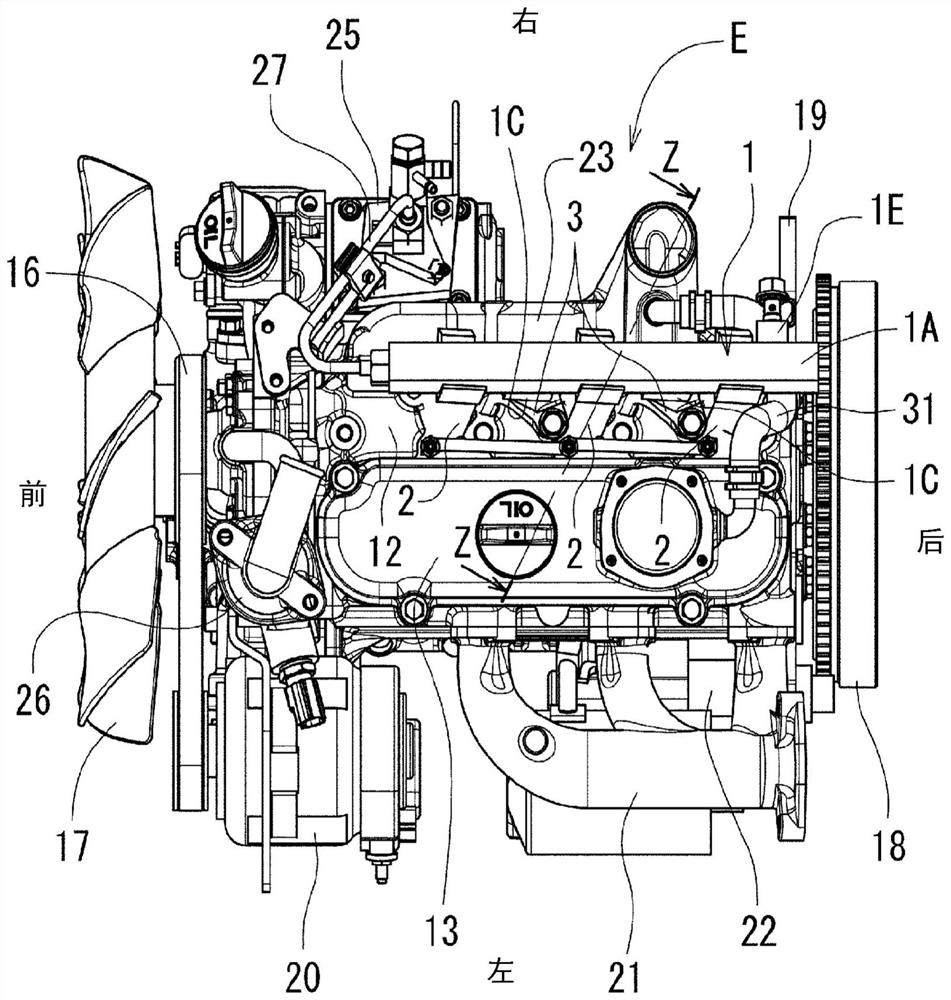

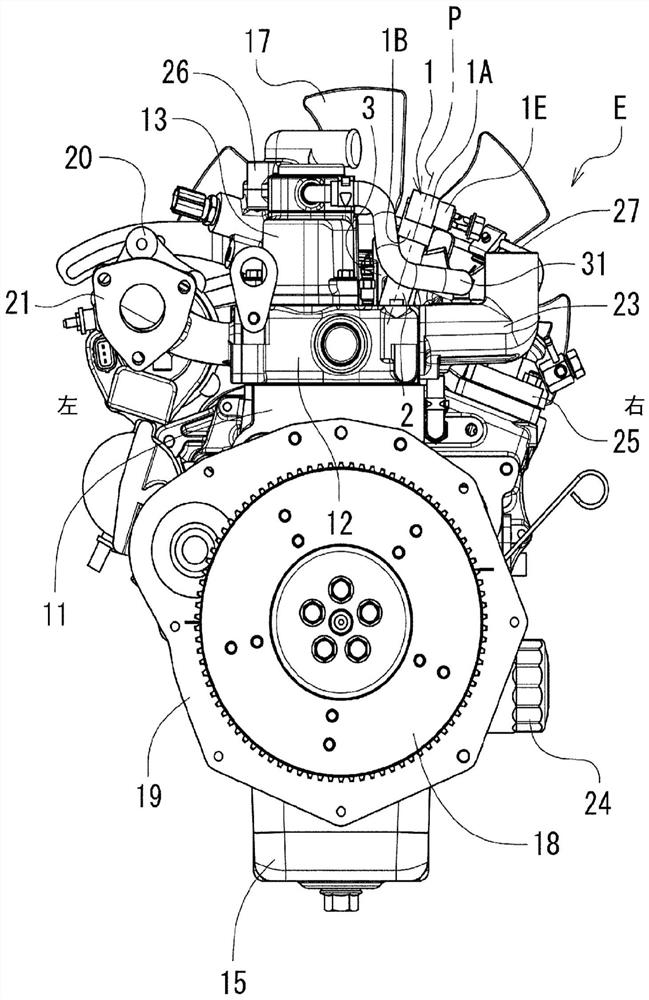

[0032] Hereinafter, in the case of an industrial diesel engine (hereinafter abbreviated as "engine") mounted on an agricultural tractor or construction equipment, an embodiment of the engine head structure of the present invention will be described with reference to the drawings. In addition, the side where the cooling fan is located in the engine is defined as the front, the side where the flywheel is located is defined as the rear, the side where the exhaust manifold is located (exhaust side) is defined as the left, and the side where the intake manifold is located (the intake side) is defined as the left. gas side) is defined as right.

[0033] Figure 1 to Figure 3 An inline three cylinder common rail industrial diesel engine is shown. In this engine E, the cylinder head 12 is attached to the cylinder block 11 , and the cylinder head cover 13 is attached to the cylinder head 12 . The transmission case 14 and the oil pan 15 are assembled in front of and below the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com