Composite material conical section shell forming mold and method

A technology of shell molding and composite materials, which is applied in the field of composite material molding, can solve problems such as inability to compact, achieve the effects of preventing potential safety hazards, ensuring the effect of compaction operations, and improving the effects of compaction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

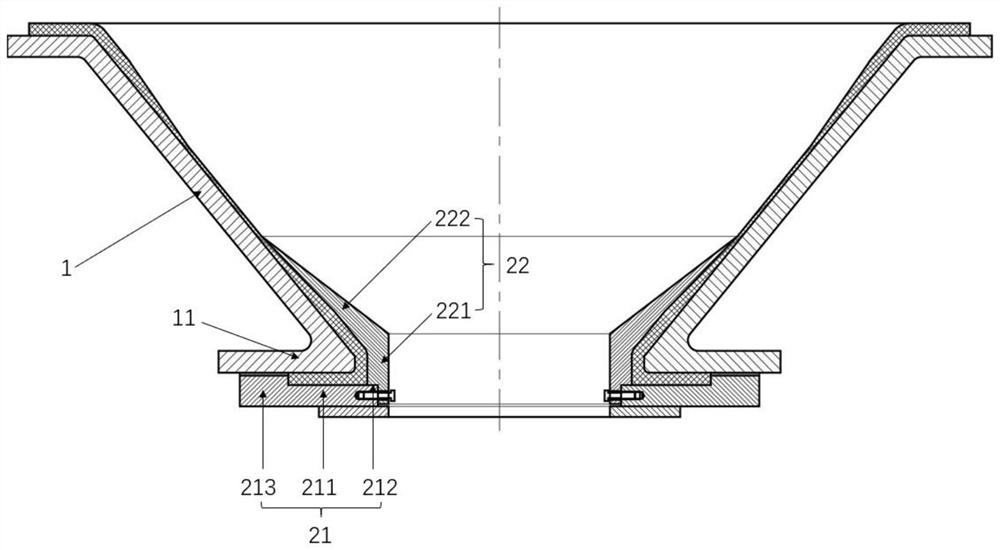

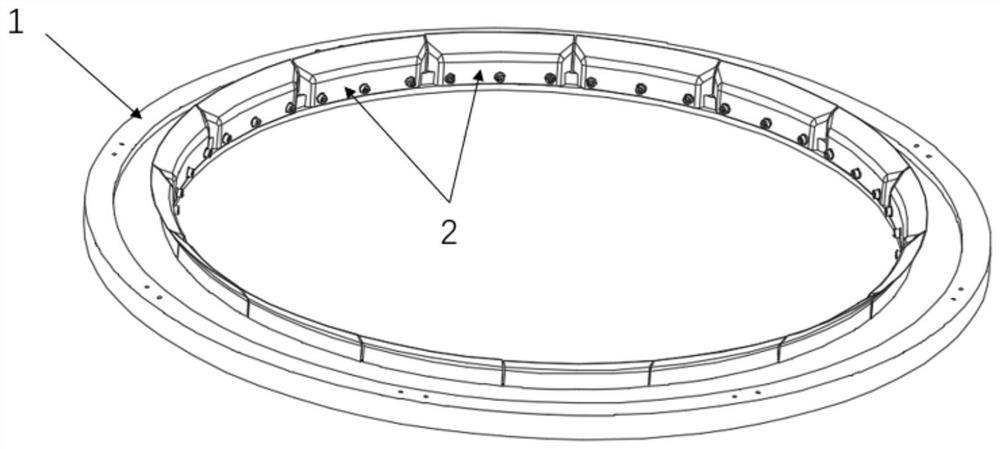

[0035] The present invention provides a mold for forming a composite material cone section shell, which includes a mold body 1 with a cone-shaped cylinder structure, and a pressing plate 2 for pressing prepreg laid on the mold body 1 . The openings at the upper and lower ends of the mold body 1 are used to connect with other structural sections. A flange connection section 11 is provided at the bottom of the mold body 1, and the flange connection section 11 is formed by folding outward along the edge of the mold body 1. The flange connection section 11 formed by turning outwards forms an angle α with the mold body 1, and the range of the angle α is less than 90 degrees. Generally, the angle α is half of the cone angle of the mold body 1. Complementary angles are formed, that is, the addition of the two equals 90°. When the angle α between the flange connection section 11 and the mold body 1 is less than 90°, the flange connection section 11 and the cylinder of the mold body 1 ...

Embodiment 2

[0041] Embodiment 2 is formed on the basis of Embodiment 1. By optimizing the structure of the side pressure plate, the effect of the compaction operation is ensured, and the potential safety hazard caused by the accidental drop of the side pressure plate during installation is prevented. specifically:

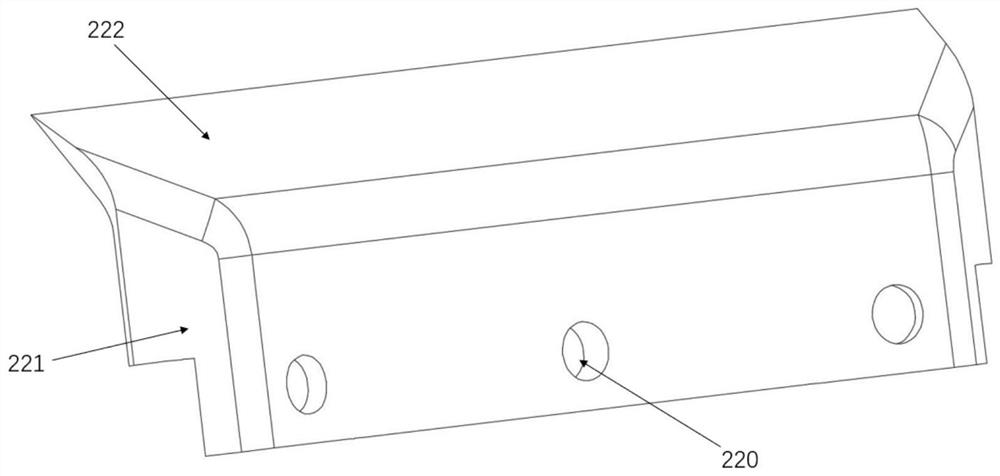

[0042] The side pressure plate 22 in an L-shaped structure as a whole includes a straight section 221 and a tapered section 222, both of which are integrally formed. Wherein, the end of the straight section 221 away from the tapered section 222 is in contact with the surface of the support section 212, and the tapered section 222 is preferably an equilateral triangle or a right triangle structure, and from the tapered section 222 to the flat One end connected to the straight section 221 gradually becomes thinner toward the other end. The thickness design of the tapered section in the side pressure plate 22 can reduce the pressure of the upper layer laid at the corner of the m...

Embodiment 3

[0046] This embodiment 3 is formed on the basis of embodiment 1 or embodiment 2. By setting the surrounding bar section in the structure of the flange platen, it not only reduces the number of parts in the structure, but also makes the flange platen and the method on the mold body The distance between the flange connection sections can be adjusted to realize the quantitative adjustment of the compression amount of the flange connection section by the flange pressure plate. specifically:

[0047] One end of the flange platen 21 is provided with a surrounding strip section 213, and the function of the surrounding strip section 213 is to form an enclosure, that is, to block, the end of the prepreg laid on the surface of the flange connection section 11, so as to prevent the prepreg from flowing out . Thus, the surrounding strip section 213 is located at the end of the flange pressing plate 21 , and the surrounding strip section 213 , the flange surface pressing section 211 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com