Multichannel loop type uniform temperature plate

A vapor chamber and multi-channel technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve the problems affecting the heat transfer efficiency of the vapor chamber, the flow of steam and liquid media, and the lack of specialization, so as to improve the thermal efficiency. The effect of transmission efficiency, simple structure and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

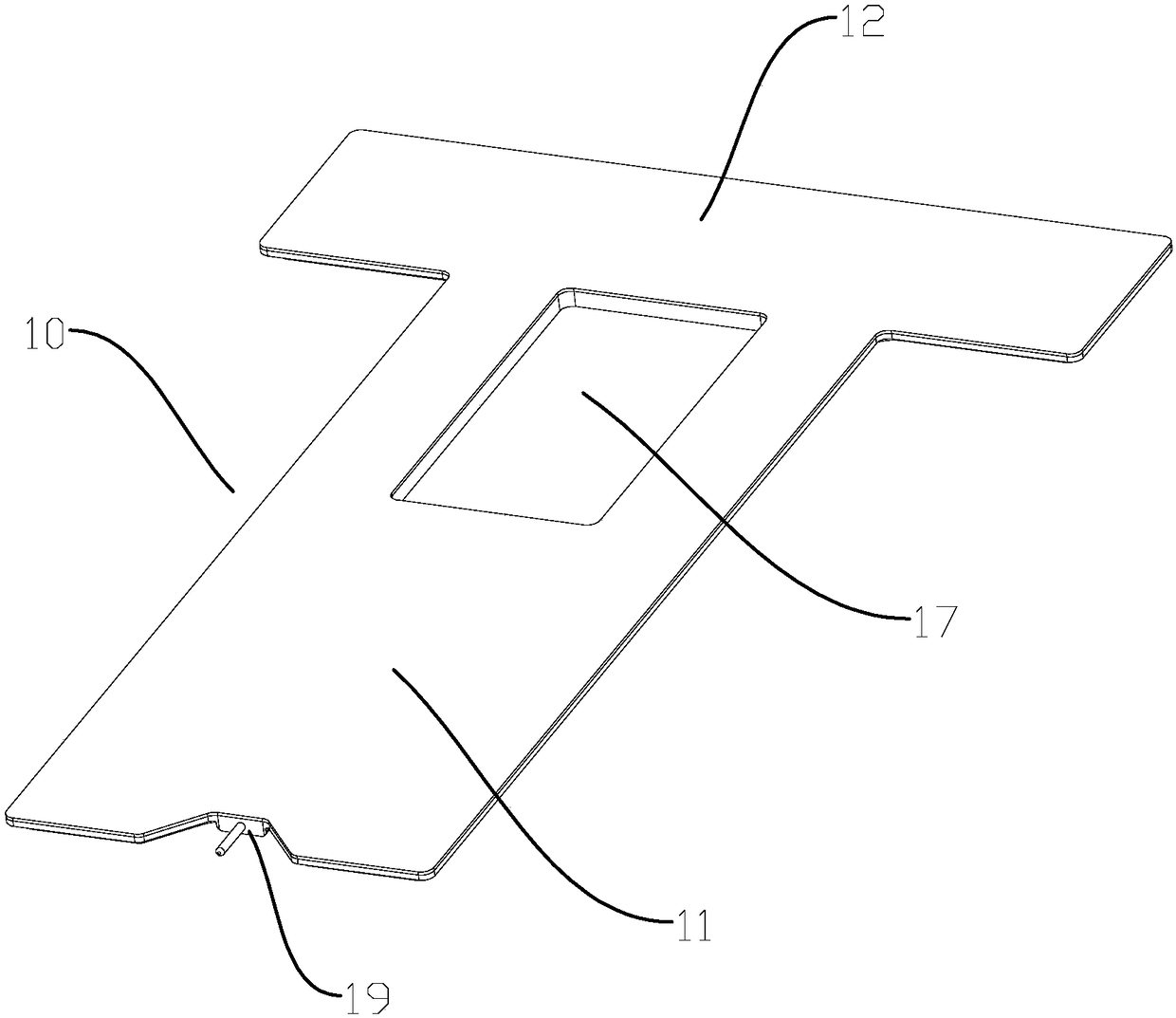

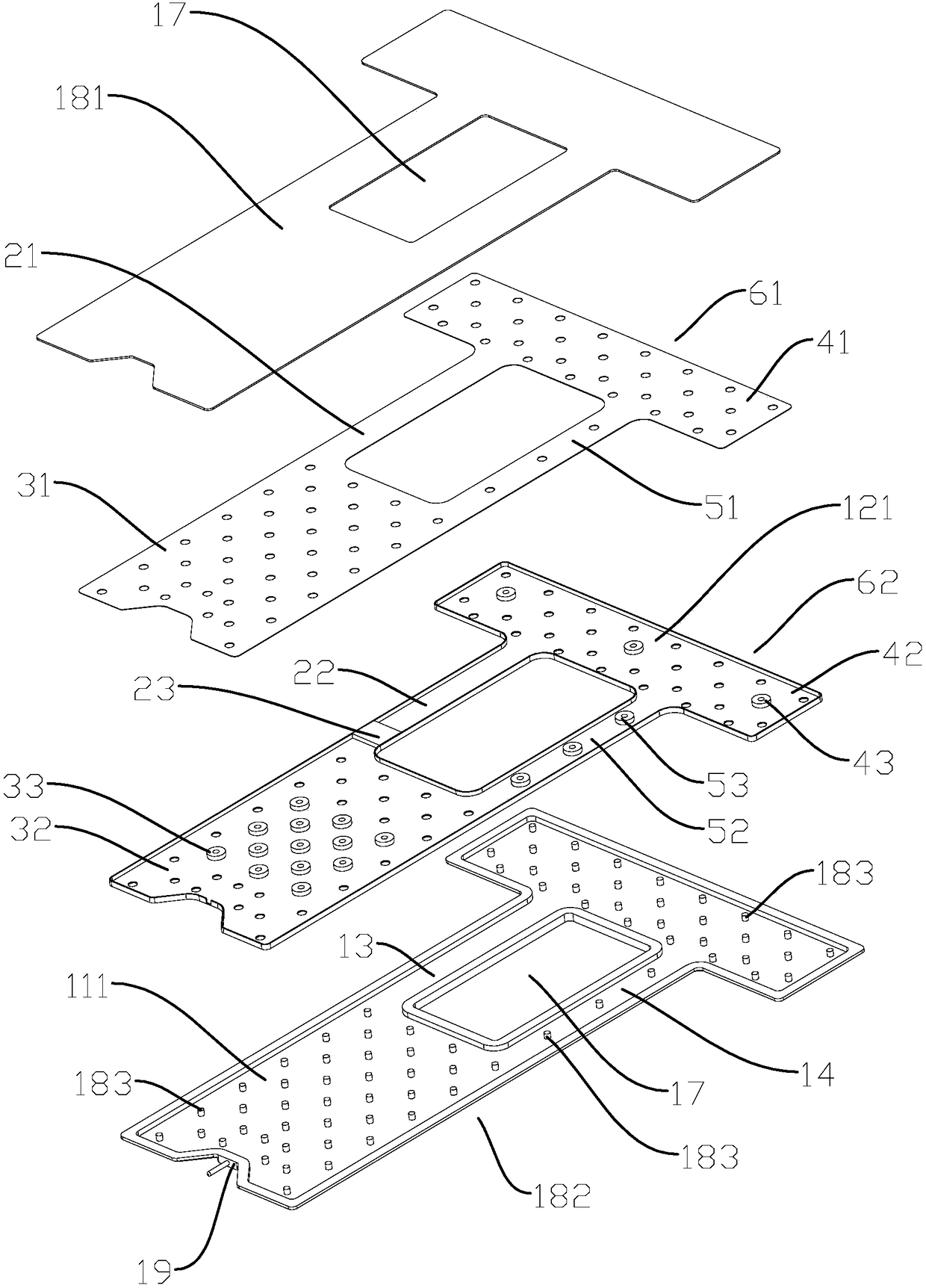

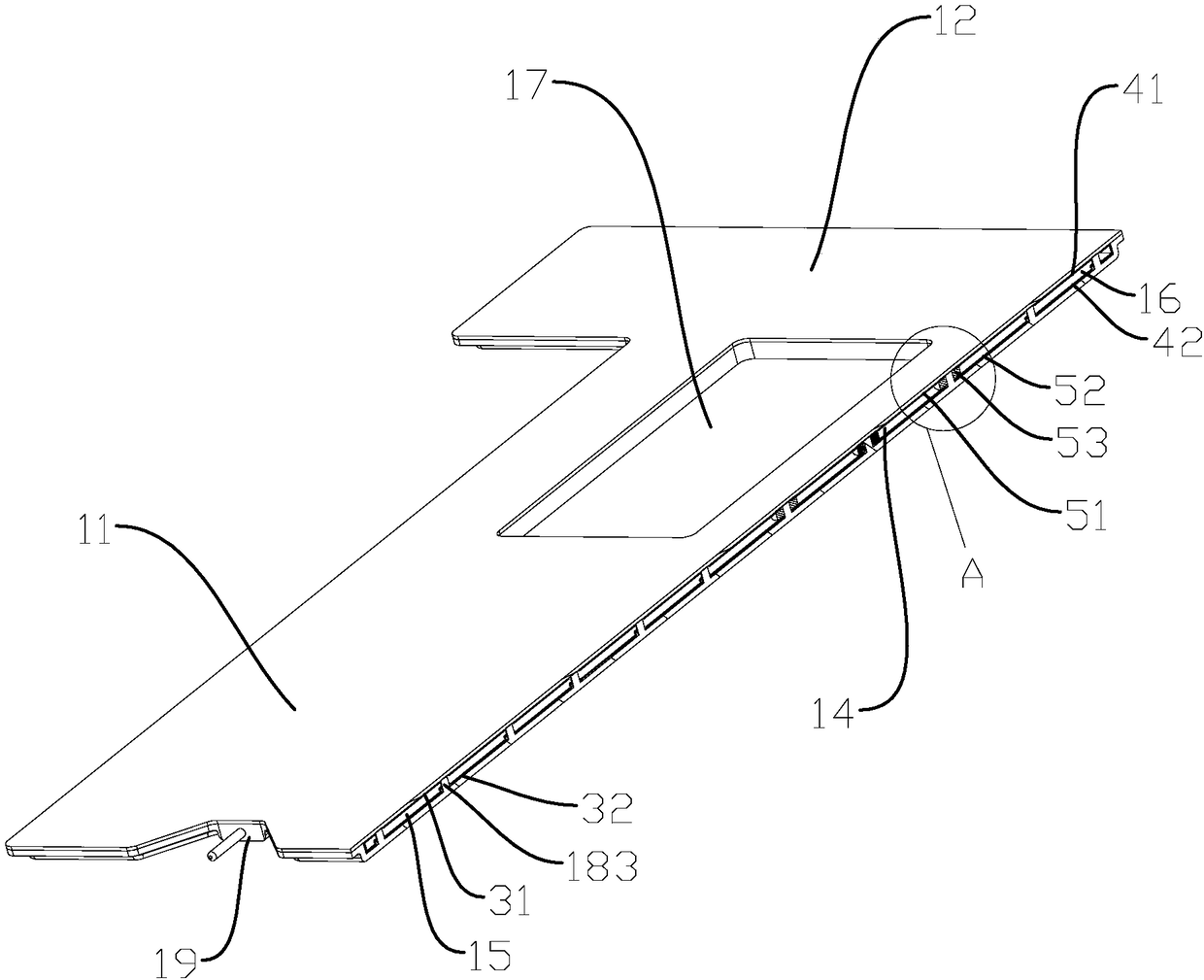

[0024] refer to Figure 1 to Figure 6 , a multi-channel loop type temperature equalizing plate, including a heat-conducting main board body 10, the main board body 10 has a heat absorption part 11 and a heat dissipation part 12, the heat absorption part 11 has a heat absorption cavity 111, and the heat absorption cavity 111 has a heat sink The heat-absorbing liquid medium, the heat-dissipating part 12 has a heat-dissipating cavity 121, and the main body 10 is provided with a liquid-medium channel 13 and a vapor channel 14 both used to connect the heat-absorbing cavity 111 and the heat-dissipating cavity 121; the heat-absorbing part 11 can absorb The heat from the outside is transferred to the liquid medium. The steam generated after the liquid medium absorbs heat can enter the heat dissipation cavity 121 through the steam channel 14. The heat dissipation part 12 can absorb the heat of the steam in the heat dissipation cavity 121. During use, the heat dissipation fins, The heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com