Automatic sampling device of dissolution tester

An automatic sampling device and dissolution apparatus technology, which is applied in the direction of instruments and analytical materials, can solve the problems of inaccurate sampling volume, inaccurate samples, and inability to meet the requirements of the Pharmacopoeia, so as to achieve accurate sampling, avoid contamination of samples, and fast and accurate automatic sampling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The automatic sampling device of the dissolution apparatus of the present invention will be described in detail below in conjunction with the accompanying drawings.

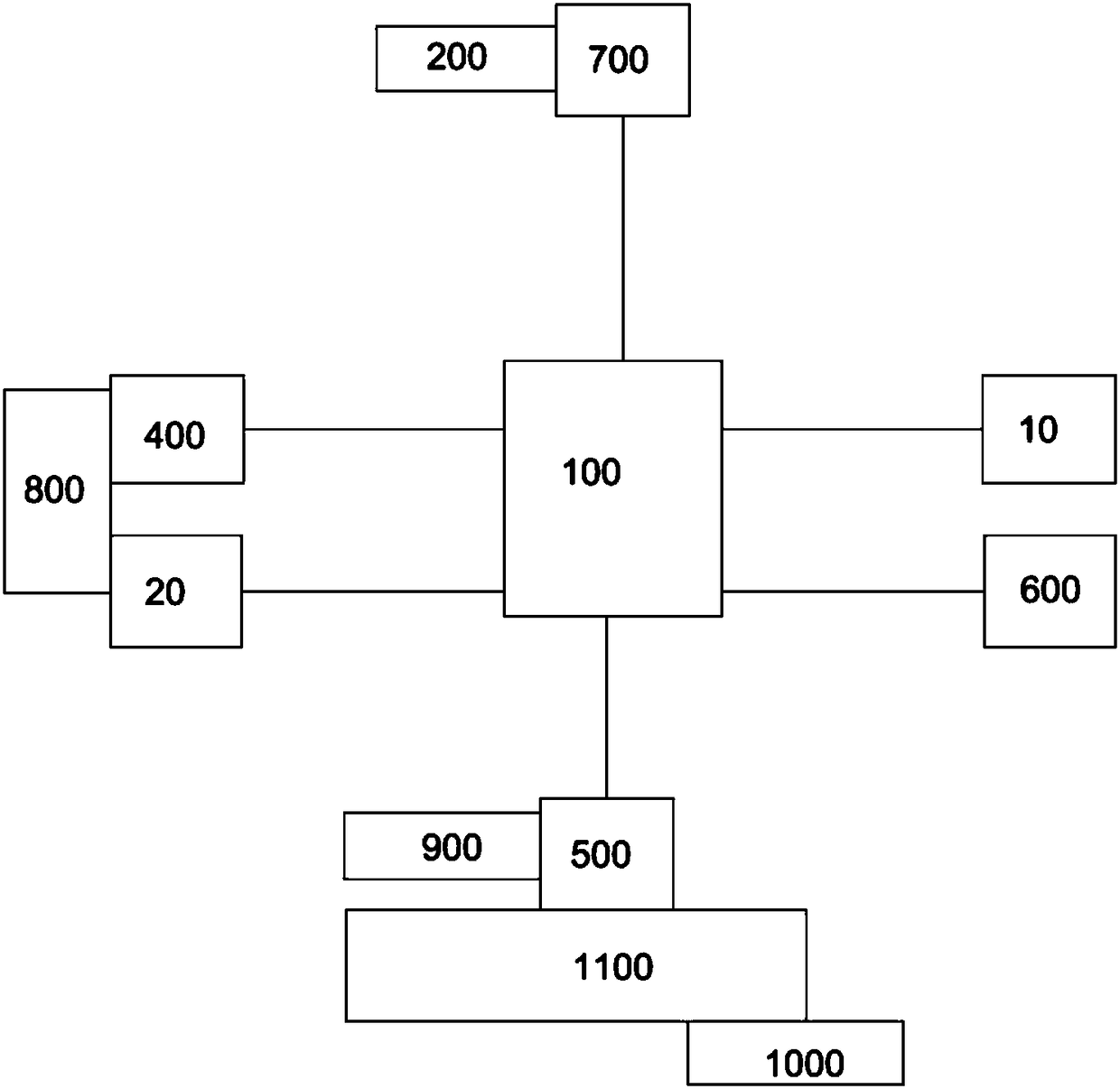

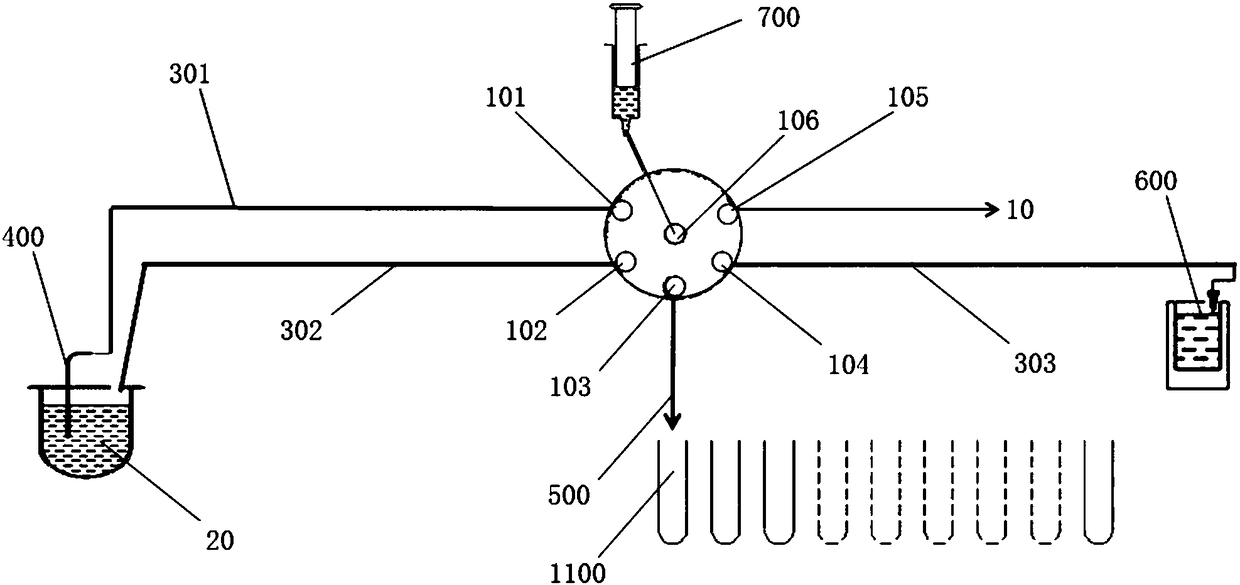

[0028] Figure 1 to Figure 5 A preferred embodiment of the automatic sampling device for the dissolution apparatus of the present invention is shown.

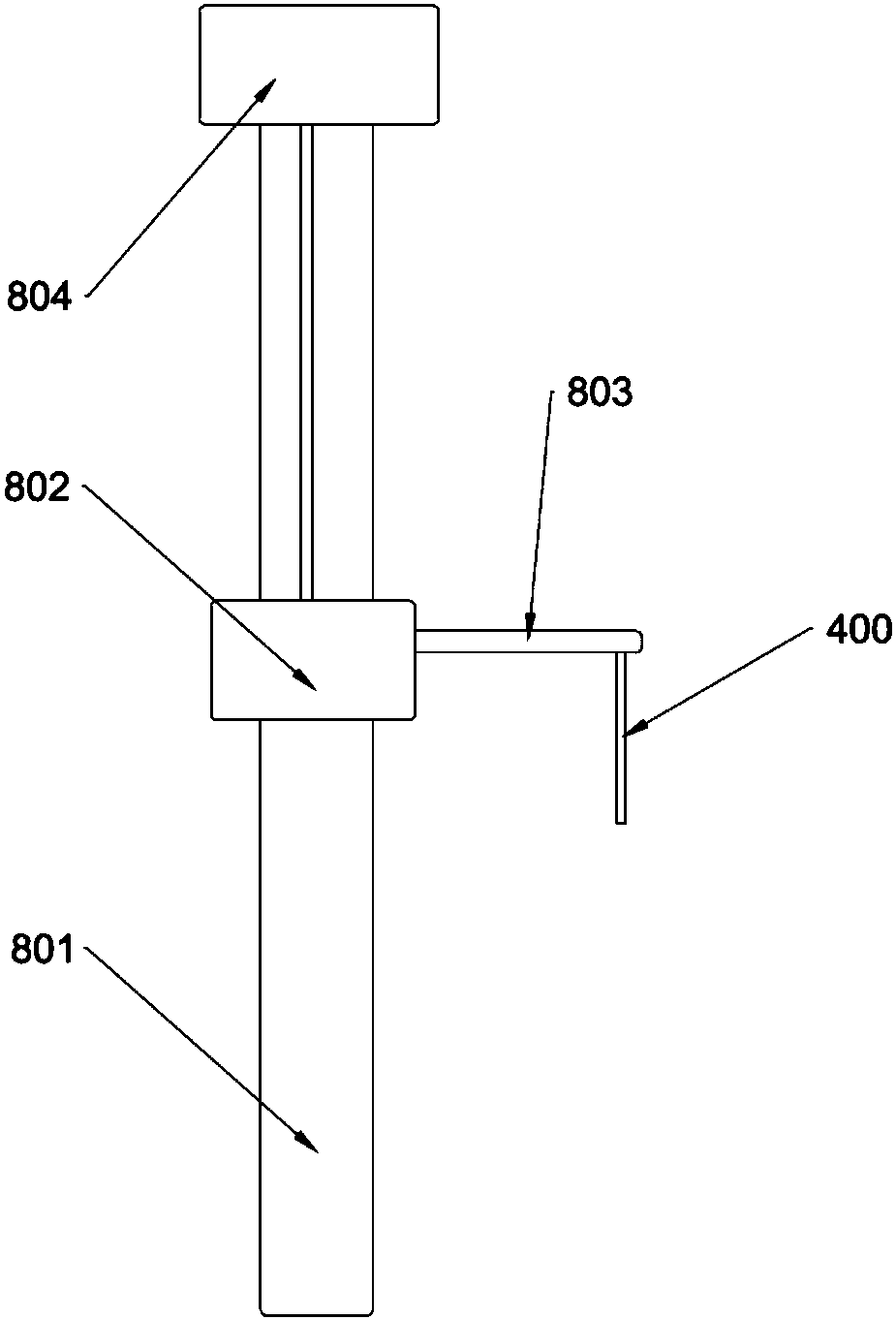

[0029] Such as Figure 1 to Figure 5 As shown, an automatic sampling device for a dissolution apparatus includes a multi-channel valve group 100 . Among them, the multi-channel valve group 100 includes a first branch 101 connected to the sampling needle 400 through a sampling pipeline 301, a second branch 102 connected to the dissolution vessel through a return pipeline 302, and a sample injection needle 500 connected to the sample. The third branch 103 of the collection device 1100 , the fourth branch 104 connected to the replenishment tank 600 through the replenishment pipeline 303 , the fifth branch 105 communicated with the external air 10 and the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com