Mass spectrometer real-time linear sampling device for 20 MPa high pressure inner range

A linear sampling and mass spectrometer technology, applied in sampling devices, measuring devices, instruments, etc., can solve problems affecting sampling accuracy, gas mixing, rapid volume expansion, etc., to achieve linear response, sensitive acquisition response, and no time delay Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

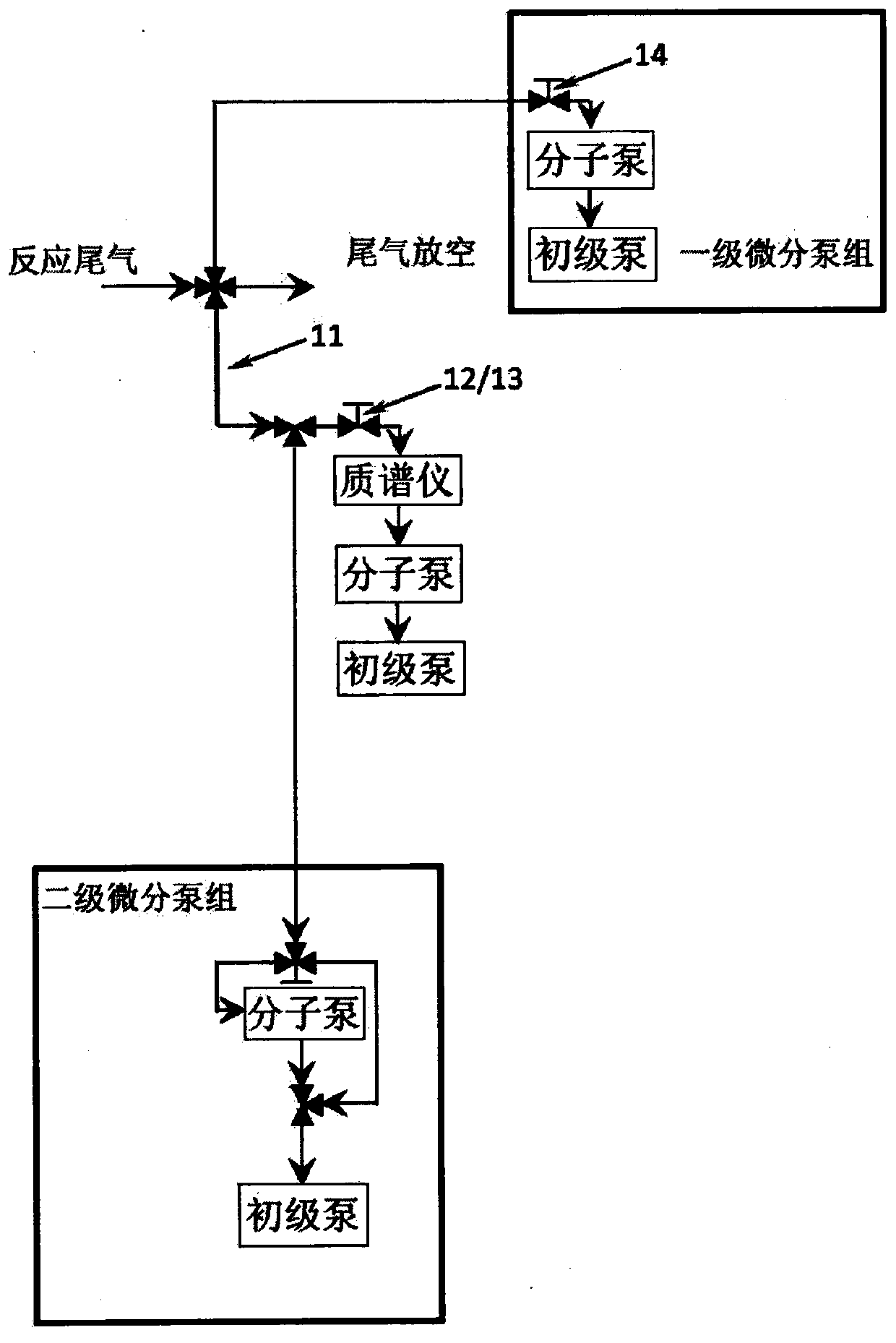

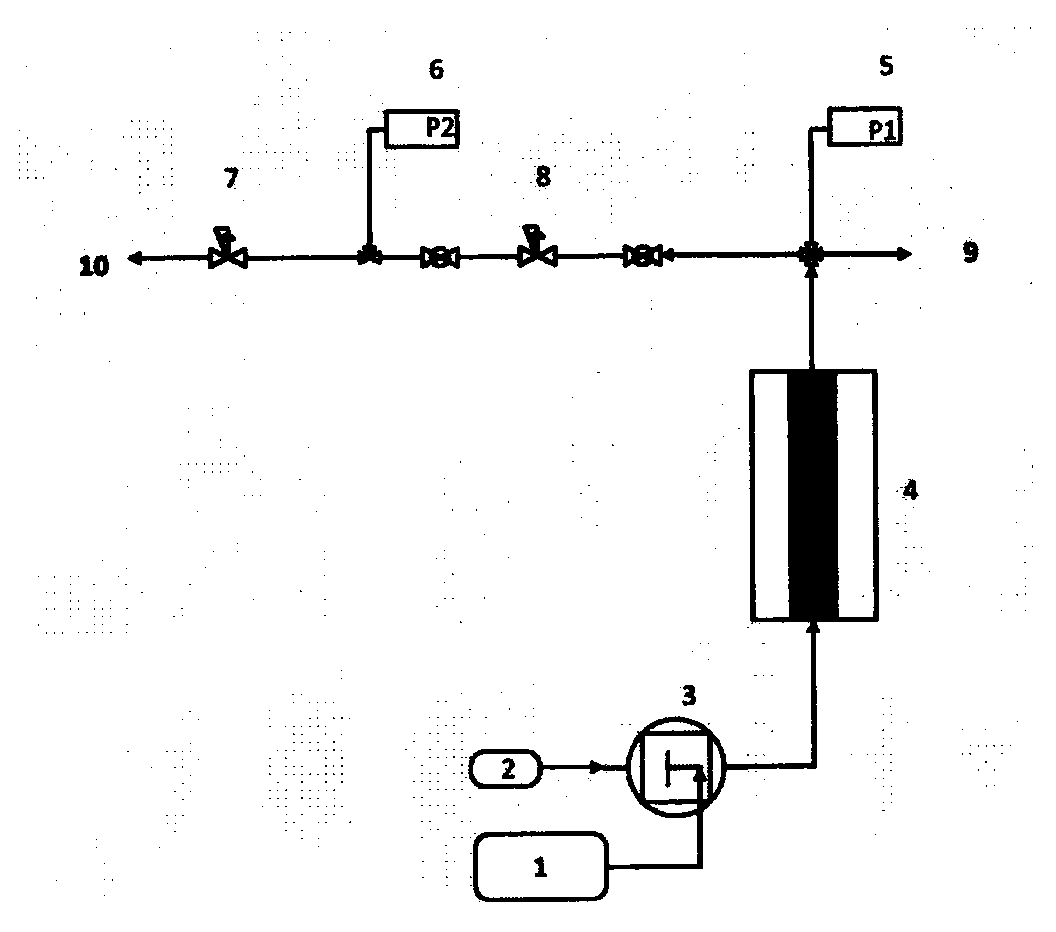

[0029] Such as figure 1 As shown, a mass spectrometer provided by the present invention adopts an imported Pfeiffer PrismaPlus electric quadrupole to match an Agilent Flexy CF interface molecular pump in the laboratory implementation of a mass spectrometer provided by a mass spectrometer in the range of 20 MPa high pressure. group and two Pfeiffer HiCube80 KF interface molecular pump groups, as a platform for testing the device of the present invention, the background air pressure is 5 × 10 when closed -9 torr.

[0030] Aiming at related technical problems, the present invention has made the following considerations in design, the sampling scheme is shown in figure 1 , the main equipment is a mass spectrometer and a molecular pump set, and the following design points are emphatically used in the connection of the pipelines, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com