O-Ti-Sb-Te-based synaptic bionic device for artificial neural network

An artificial neural network, o-ti-sb-te technology, applied in electrical components and other directions, can solve the problems of poor linear change, low bit resolution, and excessive difference between high and low resistance, and achieve the effect of excellent electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

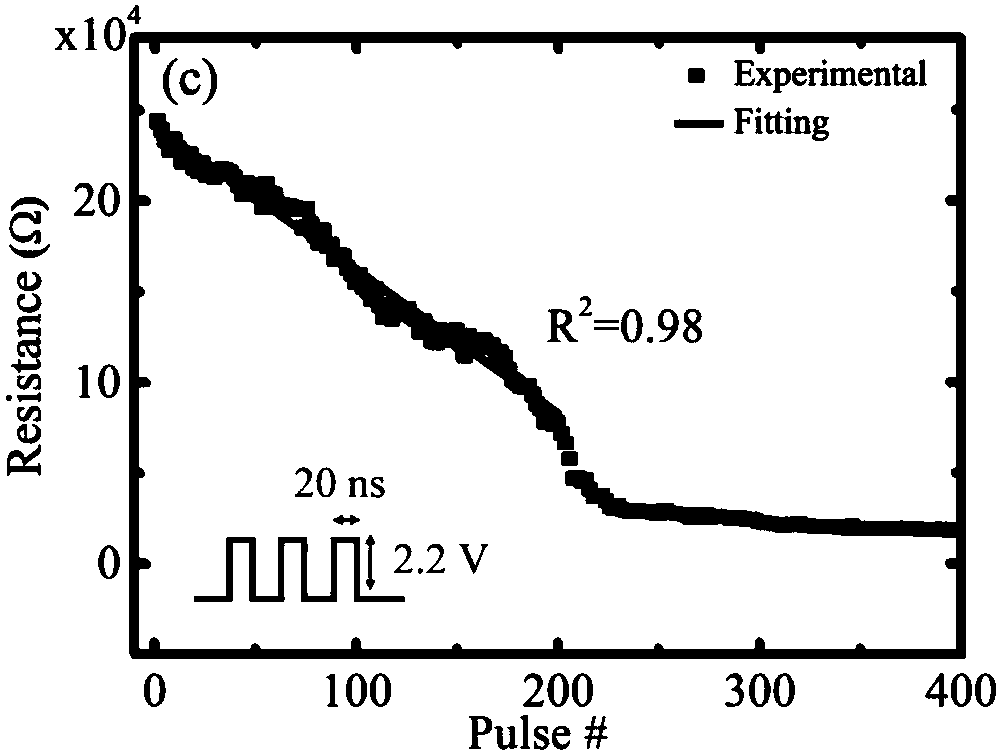

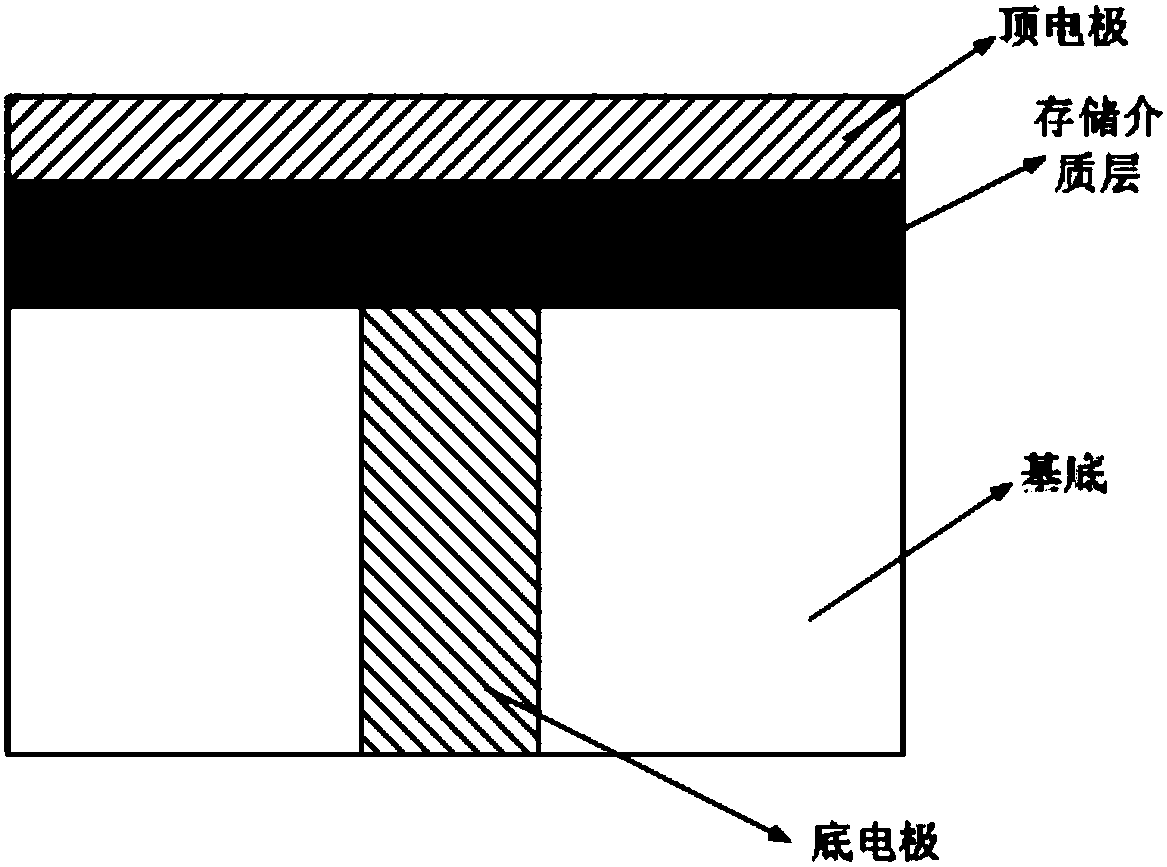

Embodiment 1

[0050] Example 1: An electrode in a medium with a diameter of 190 nanometers was prepared using a standard 0.13 micron CMOS process. The storage medium layer is deposited by physical vapor deposition with a thickness of 120 nanometers, and the O layer above the electrode is prepared through glue coating, photolithography, etching and other processes. 6 (Ti 0.4 Sb 2 Te 3 ) 94 material pattern such that O above each bottom electrode 6 (Ti 0.4 Sb 2 Te 3 ) 94 The materials are electrically insulated from each other. The top electrode titanium nitride TiN was deposited by physical vapor deposition with a thickness of 20 nanometers, and the O 6 (Ti 0.4 Sb 2 Te 3 ) 94 above the TiN electrode material pattern so that each O 6 (Ti 0.4 Sb 2 Te 3 ) 94 The upper top electrode materials are electrically insulated from each other. get based on O 6 (Ti 0.4 Sb 2 Te 3 ) 94 The T-shaped synaptic bionic unit of the material; and the performance parameters of the product a...

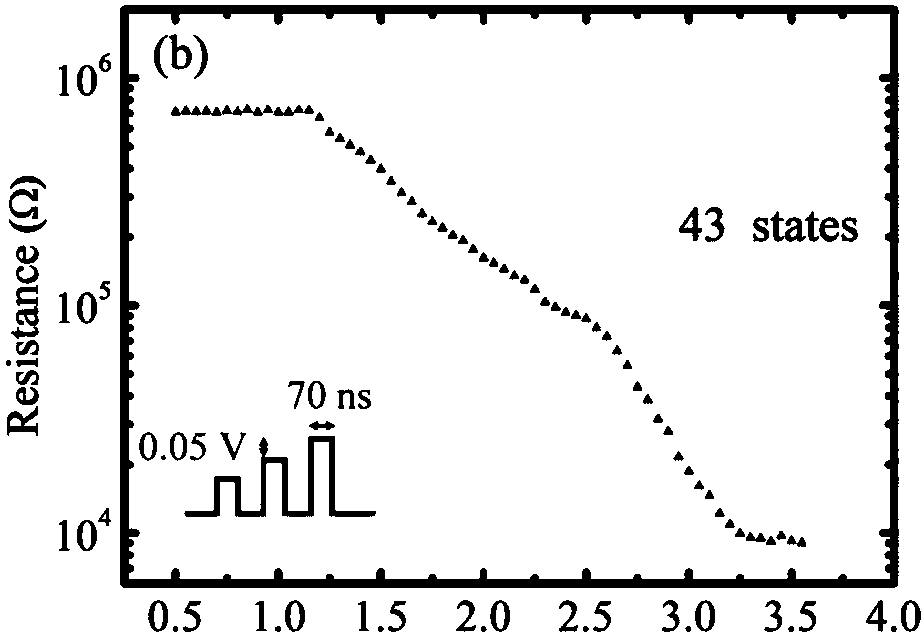

Embodiment 2

[0053] Example 2: An electrode in a medium with a diameter of 190 nanometers was prepared using a standard 0.13 micron CMOS process. The storage medium layer is deposited by chemical vapor deposition with a thickness of 200 nanometers, and the O layer above the electrode is prepared through glue coating, photolithography, etching and other processes. 10 (TiSb 40 Te 10 ) 90 material pattern such that O above each bottom electrode 10 (TiSb 40 Te 10 ) 90 The materials are electrically insulated from each other. The top electrode titanium nitride TiN was deposited by physical vapor deposition with a thickness of 200 nm, and O 10 (TiSb 40 Te 10 ) 90 above the TiN electrode material pattern so that each O 10 (TiSb 40 Te 10 ) 90 The upper top electrode materials are electrically insulated from each other. get based on O 10 (TiSb 40 Te 10 ) 90 The T-shaped synaptic bionic unit of the material; and the performance parameters of this product are that the difference be...

Embodiment 3

[0054] Example 3: An electrode in a medium is prepared by using a standard CMOS process, with a diameter of 10 nanometers. The storage medium layer is deposited by chemical vapor deposition with a thickness of 50 nanometers, and the O layer above the electrode is prepared through glue coating, photolithography, etching and other processes. 3 (TiSb 10 Te 10 ) 97 material pattern such that O above each bottom electrode 3 (TiSb 10 Te 10 ) 97 The materials are electrically insulated from each other. The top electrode titanium nitride TiN was deposited by physical vapor deposition with a thickness of 20 nanometers, and the O 3 (TiSb 10 Te 10 ) 97 above the TiN electrode material pattern so that each O 3 (TiSb 10 Te 10 ) 97 The upper top electrode materials are electrically insulated from each other. get based on O 3 (TiSb 10 Te 10 ) 97 The T-shaped synaptic bionic unit of the material; and the performance parameters of this product are that the difference between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com