Transparent wafer edge extraction method of pre-alignment machine

A pre-aligner and edge extraction technology, applied in the semiconductor field, can solve the problems of different light transmittance, difficult to calculate, unable to reflect the edge position of the transparent wafer, etc., to meet the sampling requirements, high precision, and low computational complexity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

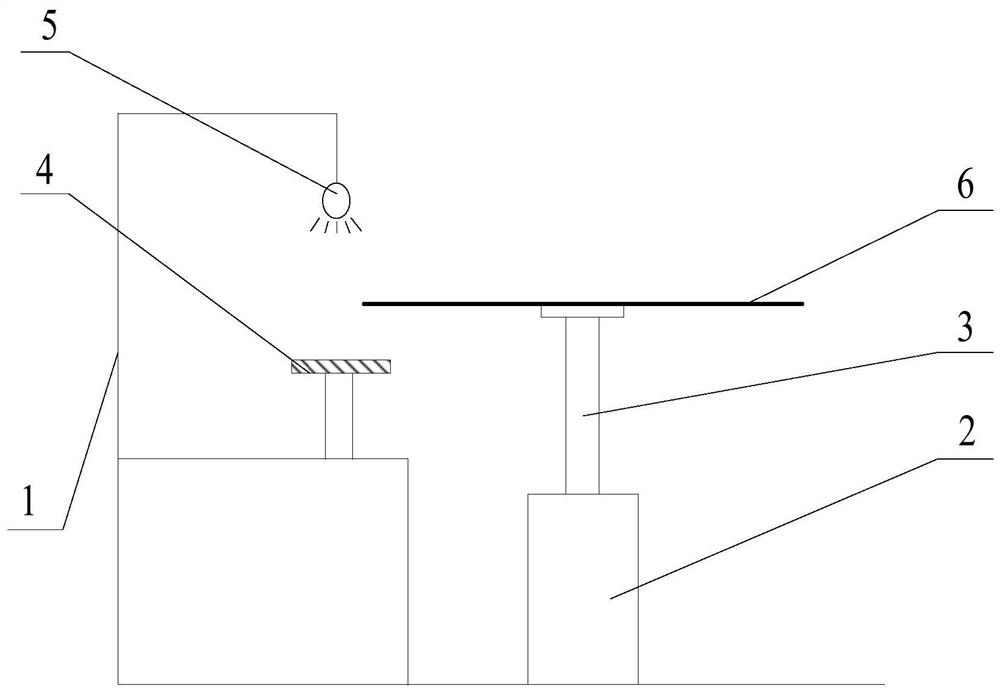

[0032] figure 1 Shows the principle block diagram of the pre-alignment machine to extract the edge of the wafer, the pre-alignment machine includes a pre-alignment support 1, a mobile platform 2, a rotating platform 3, a linear array CCD sensor 4 and a supporting light source 5, a linear array CCD sensor 4 and The matching light sources 5 are erected on the pre-alignment support 1 and placed opposite to each other in the center. The wafer is placed on the rotary platform 3, and the rotary platform 3 drives the wafer to rotate around the z-axis. The rotary platform 3 is provided with a vacuum air circuit for absorbing the wafer 6. The rotary platform 3 is placed on the mobile platform 2, and the mobile platform 2 drives the rotating platform 3 to move in the x-y direction, so that the wafer 6 moves between the linear CCD sensor 4 and the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com