EMC testing system applicable to rotary load and testing method thereof

A test system, a technology of rotating load, applied in the direction of engine test, machine/structural component test, measurement of electricity, etc., which can solve the problems of complicated test installation process, leakage, improper installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

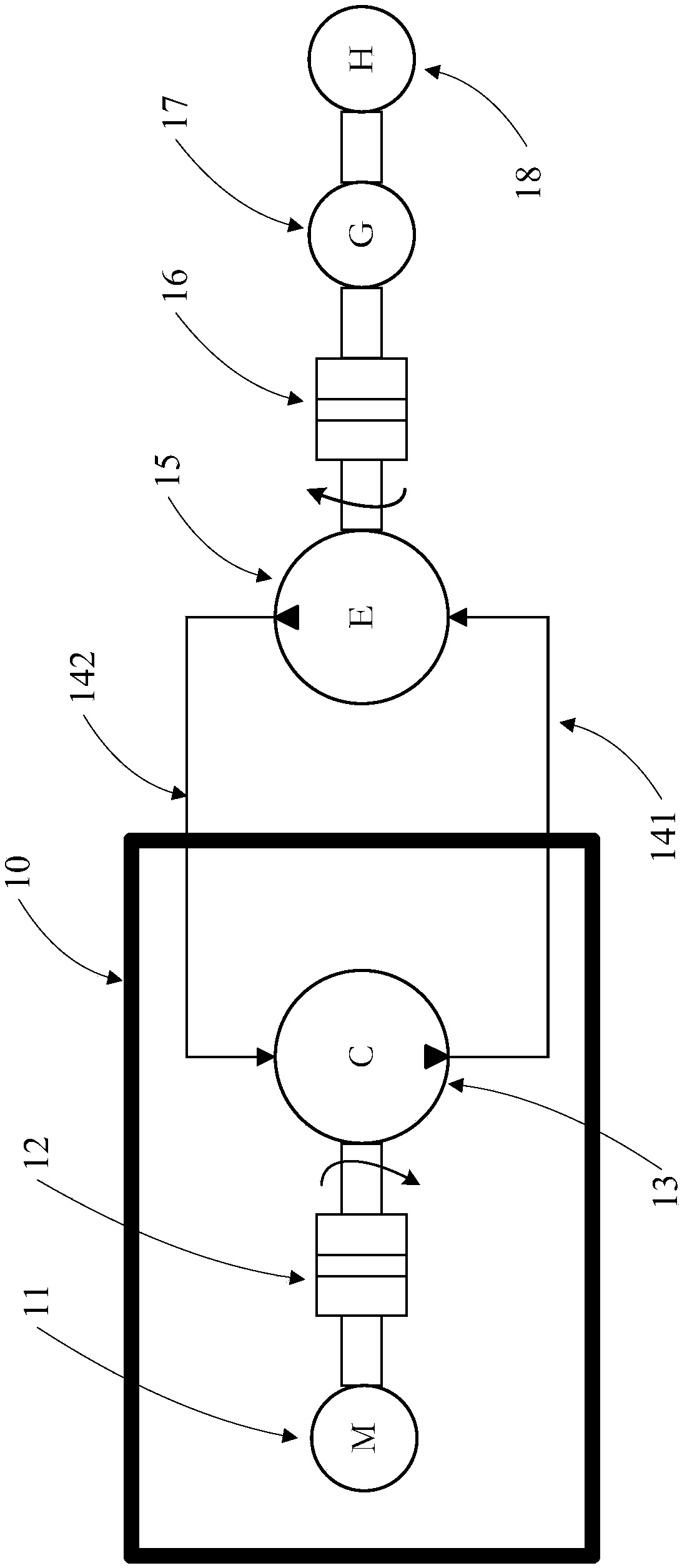

[0025] refer to figure 1 , the EMC testing system of the present invention is suitable for the rotating load 11, the rotating load 11 can be a motor or a generator, as long as it is a rotating load, it can be applicable to the present invention. The EMC test system includes a shielding room 10, a rotating load 11, a first connecting shaft 12, a compressor 13, a fluid pipeline, a fluid motor 15, a second connecting shaft 16, a motor load 17 and a consumption load 18, and the shielding room 10 can also be an EMC In the dark room, the rotating load 11, the first connecting shaft 12 and the compressor 13 are arranged in the shielding room 10, the rotating load 11 is connected to the compressor 13 through the first connecting shaft 12, and the first connecting shaft 12 adopts a conventional transmission mechanism. The transmission of special materials is not required, and the rotation of the rotating load 11 and the transmission of the connecting shaft drive the compressor 13 to wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com