Prediction method of reliability of operation temperature rise of large and medium-sized motors

A technology of operating temperature and prediction method, which is applied in the direction of motor control, electrical components, electrical digital data processing, etc., and can solve problems such as uncertain temperature rise of motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0110] The motor used for the main water pump of a pumping station is a synchronous motor with a rated voltage of 6000V, a rated current of 180A, a number of phases of 3, an insulation class of F, a core mass of 3.693t, a core height of 370mm, and the number of ventilation channels 6, the height of the ventilation groove is 10mm, the inner diameter of the iron core is 2290mm, the outer diameter of the iron core is 2600mm, the height of the ventilation groove is 10mm, the width of the groove is 18mm, the length of the iron core is 155mm, the number of ventilation grooves is 216, and the stator is 75°C The phase resistance is 0.2416Ω, the exciting current under the rated load is 177A, and the winding resistance is 0.6398Ω.

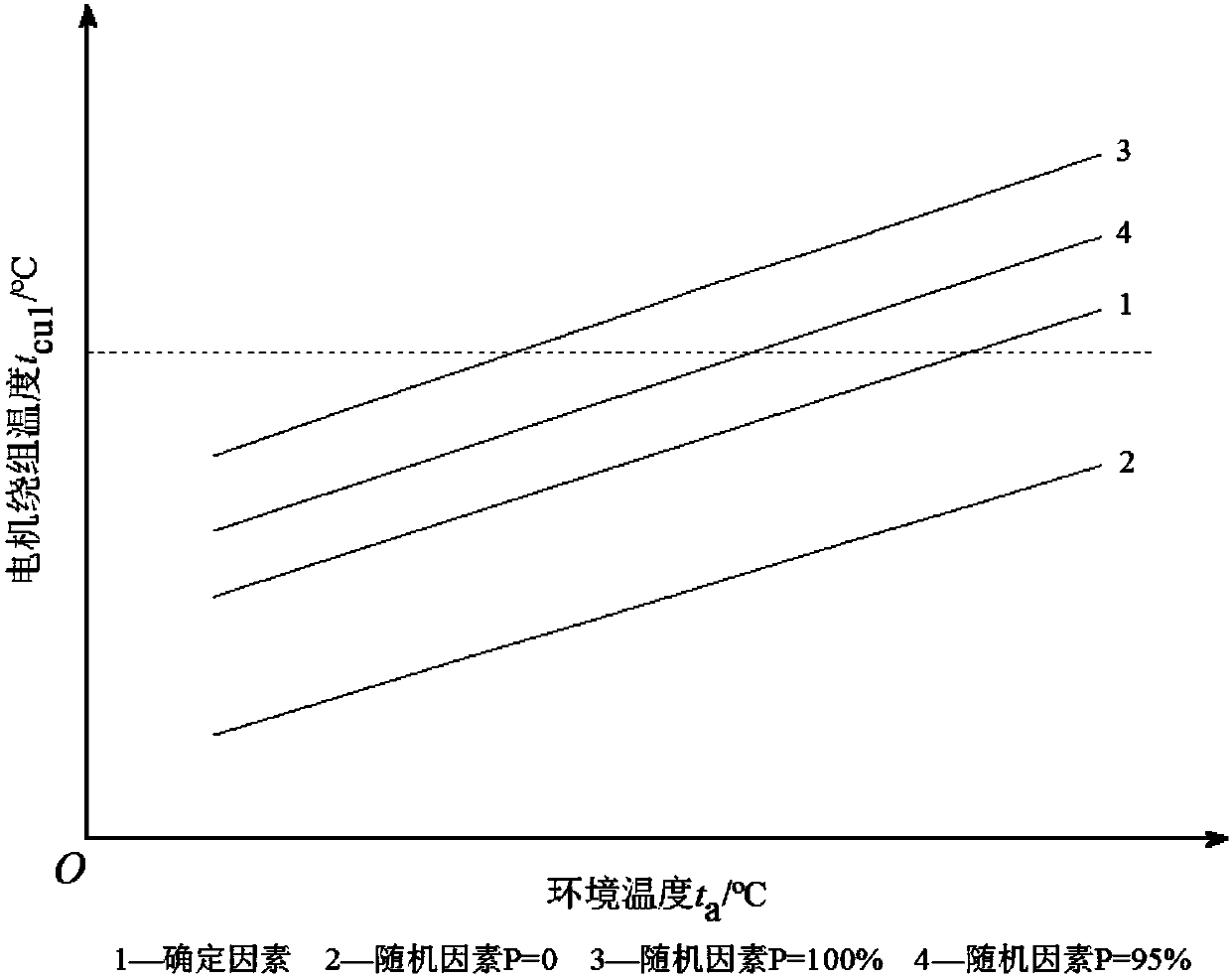

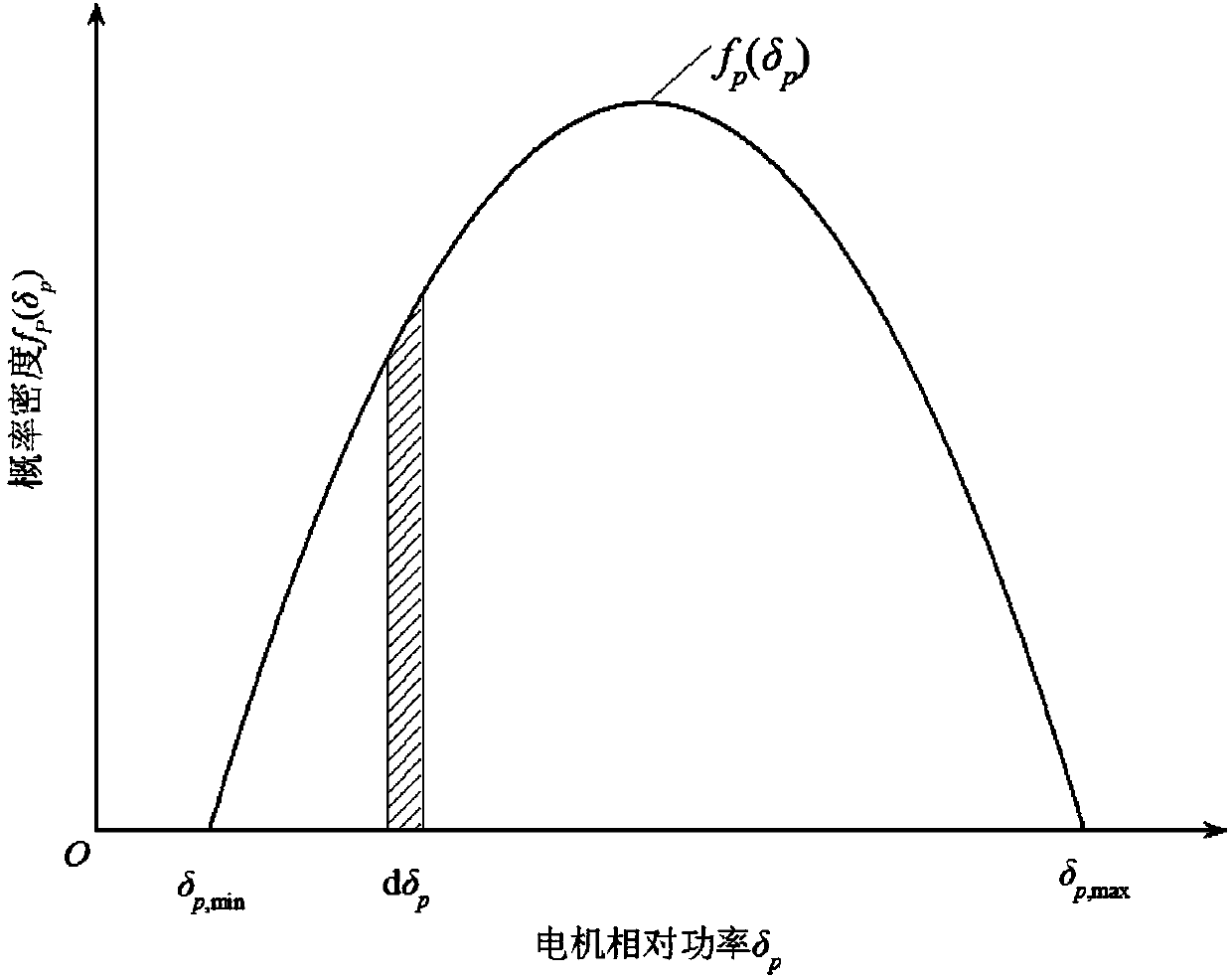

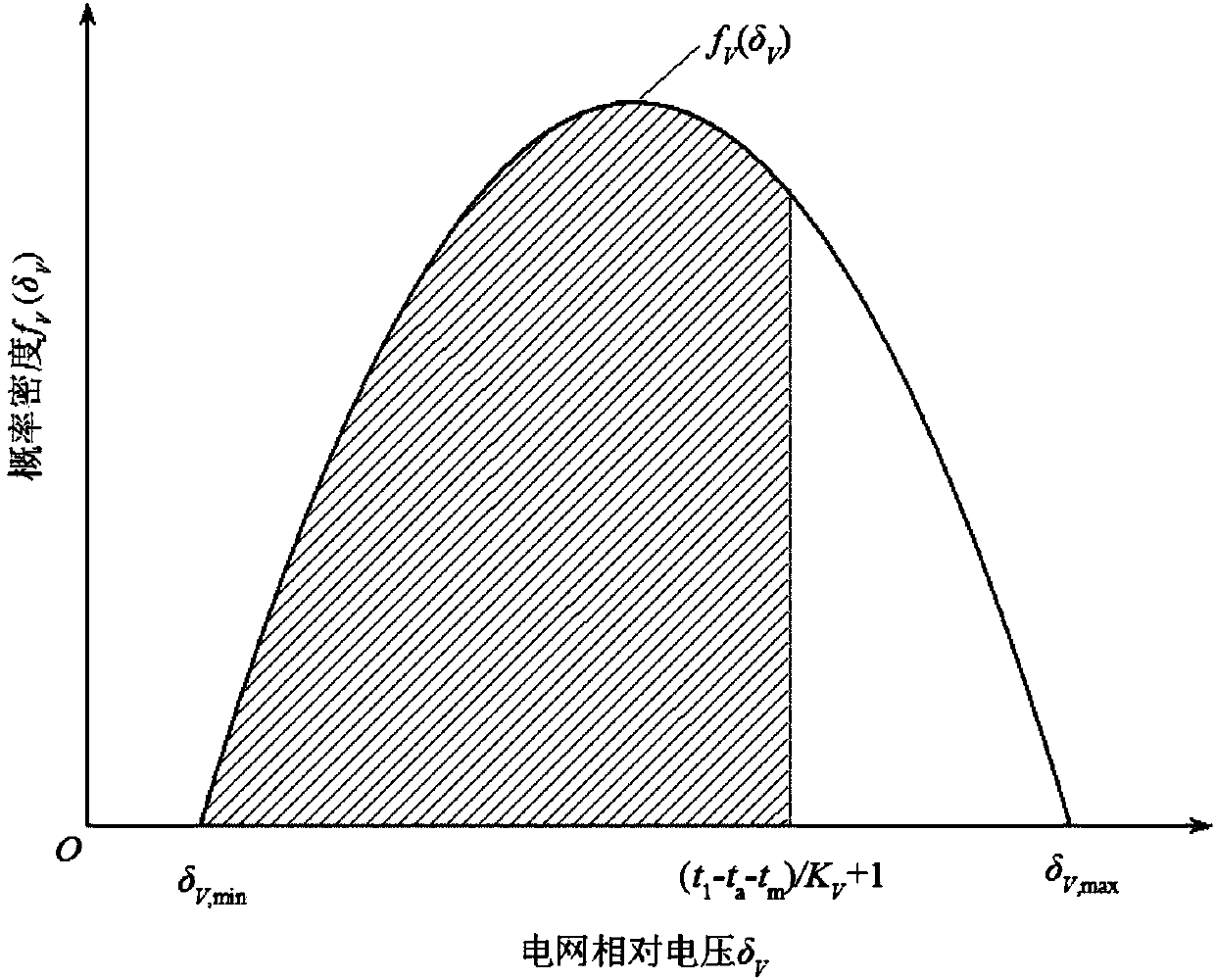

[0111] In step A, the main factors affecting the temperature rise of the motor winding are determined:

[0112] When the ambient temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com