Improved analysis method for bulk material flow characteristic under unilateral excitation nonlinear unloading system

A technology of bulk materials and analysis methods, applied in special data processing applications, complex mathematical operations, instruments, etc., can solve the problems of variable flow of bulk materials, fatigue wear, unloading equipment can not meet the automatic unloading of bulk materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

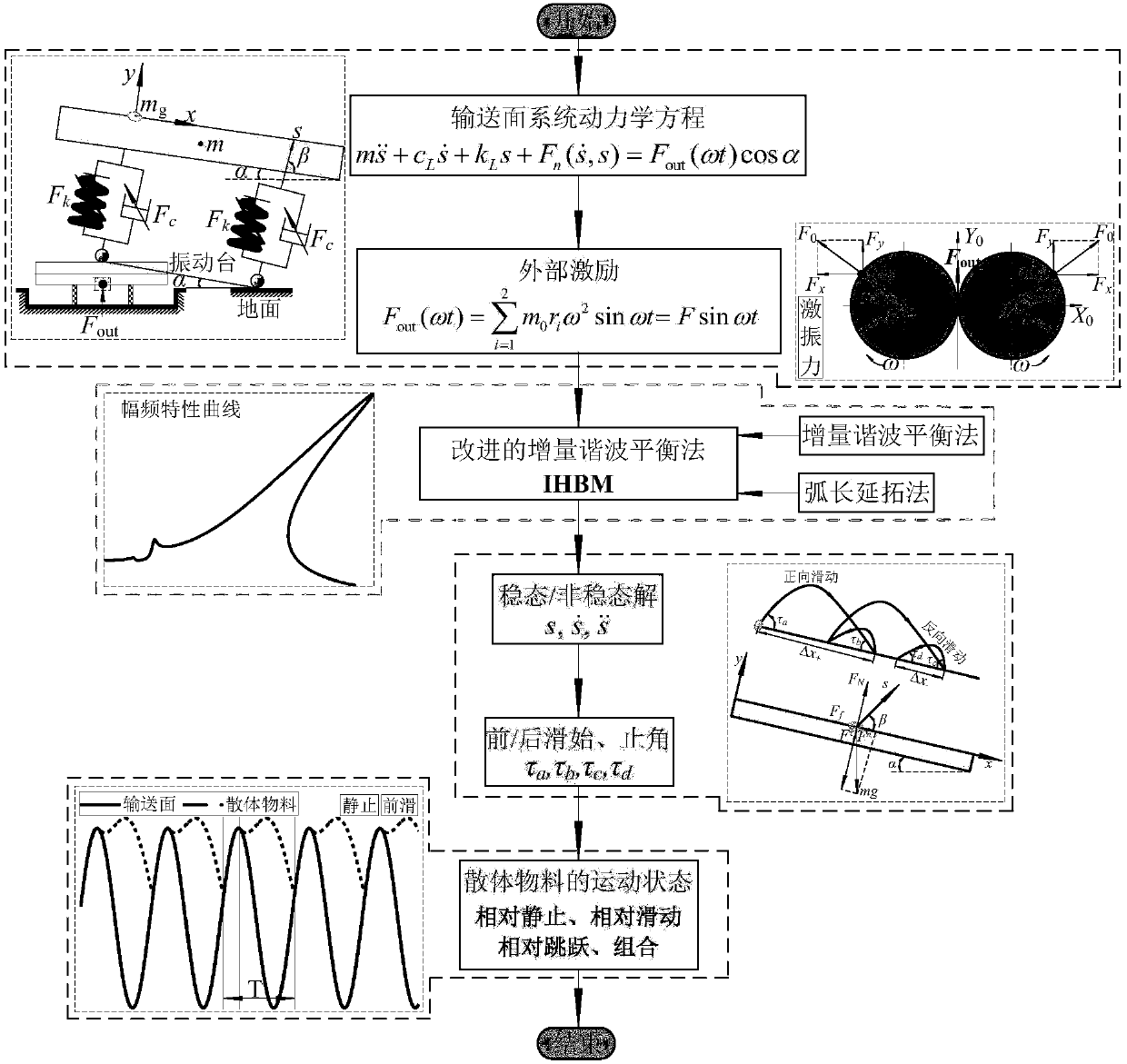

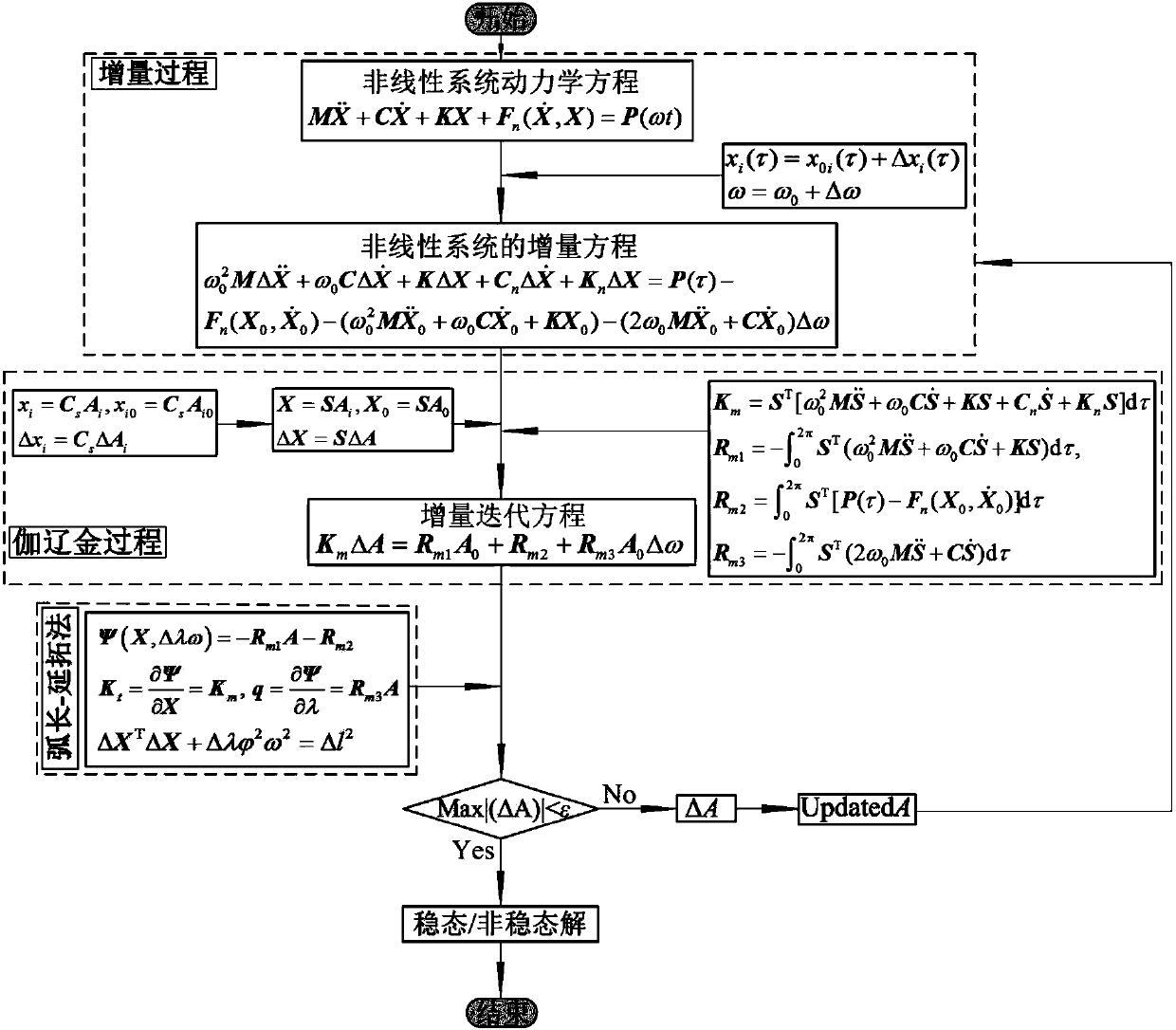

[0075] The embodiment of the present invention is an improved method for analyzing the flow characteristics of bulk materials in a single-side excitation nonlinear unloading system. The flow chart is as follows figure 1 shown, including the following steps:

[0076] Step 1, determine the dynamic equation of the nonlinear unloading system with one-sided excitation;

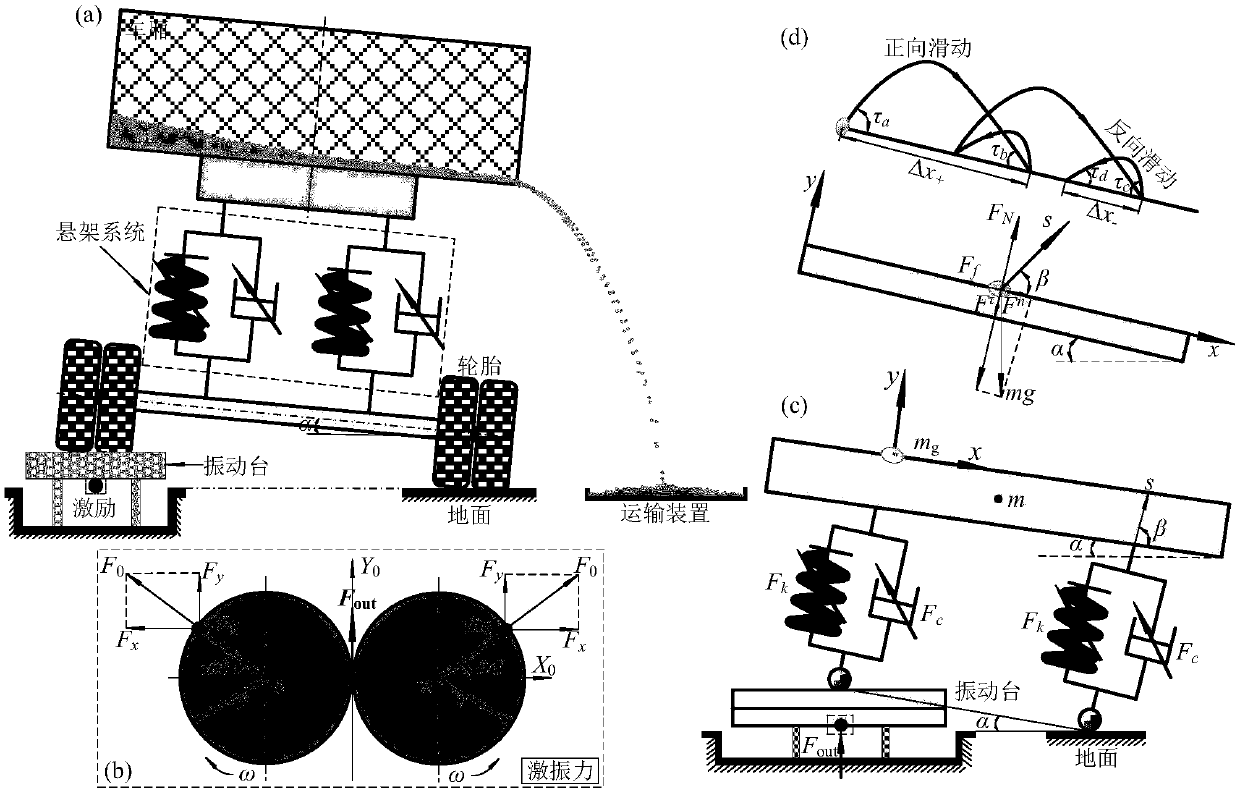

[0077] according to figure 2 On the basis of simplifying the physical model of the nonlinear unloading system with one-sided excitation, the expressions of its dynamic differential equations are deduced, and the various expressions are determined;

[0078] Step 1-1, the dynamic equation of the nonlinear unloading system with unilateral excitation is:

[0079]

[0080] In the formula, m is the equivalent mass of the unloading equipment, α is the roll a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com