Cleaning machine flower basket for cleaning diamond cutting line

A cleaning machine, diamond wire technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the surface contamination of silicon wafers, affecting product quality, hindering the surface of silicon wafers, etc., to achieve light weight, overall The effect of stable connection and increased cleaning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

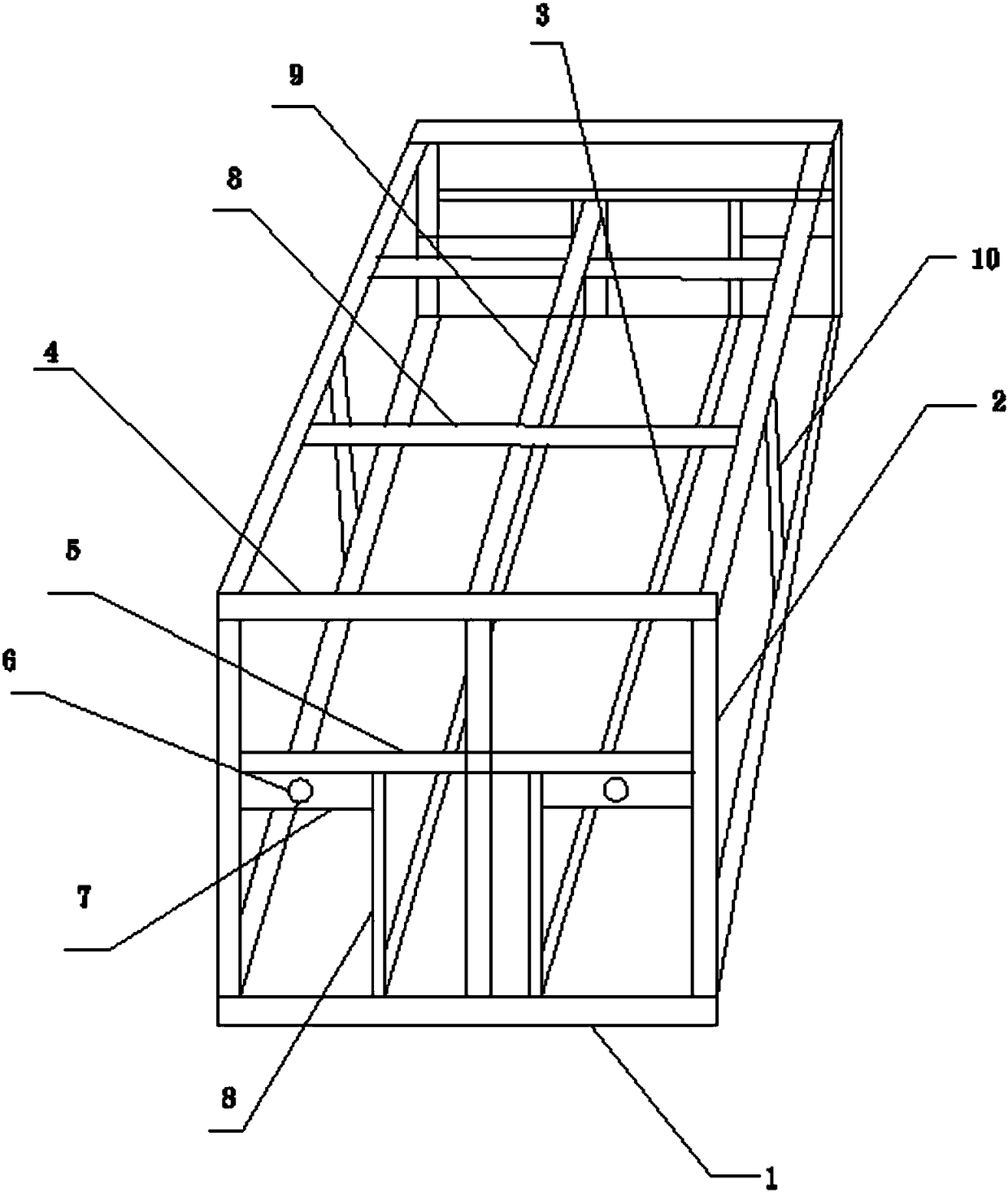

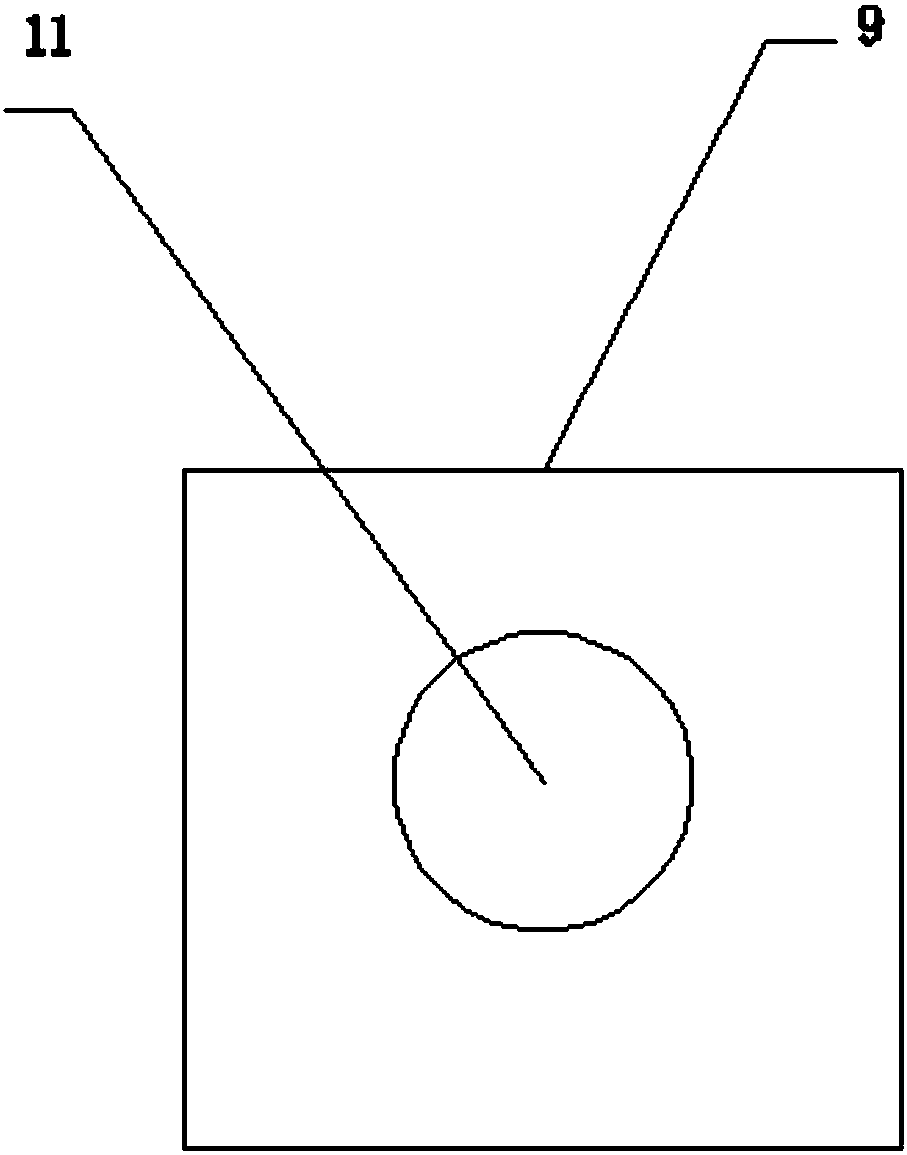

[0016] This embodiment provides a cleaning machine flower basket for diamond wire cleaning, the structure is as follows Figure 1-2 As shown, including the frame body, the frame body is made of high-strength aluminum alloy material, the frame body is composed of a base and a side frame fixed on the base, the base is surrounded by four base cylindrical pipe strips 1 to form a four-sided structure; and on the base Two supporting bars 3 are arranged longitudinally, and they are arranged equidistantly. The side frame includes a side frame and an upper frame. The fixed strip 5 is fixed between the side frame cylindrical pipe strips 2 on both sides of the front end and the rear end, and the first fixed connection strip 8 is provided between the fixed strip 5 and the base cylindrical pipe strip 1 at the corresponding end of the base respectively, and the side frame cylinder A connection plate 7 is provided between the shaped pipe bar 2 and its adjacent first fixed connection bar 8, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com