Derusting polishing device for steel

A technology for equipment and steel, applied in the field of rust removal and polishing equipment for steel, can solve the problems of heavy workload, inability to adapt to mass production, cumbersome rust removal process, etc., and achieve the effect of improving rust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

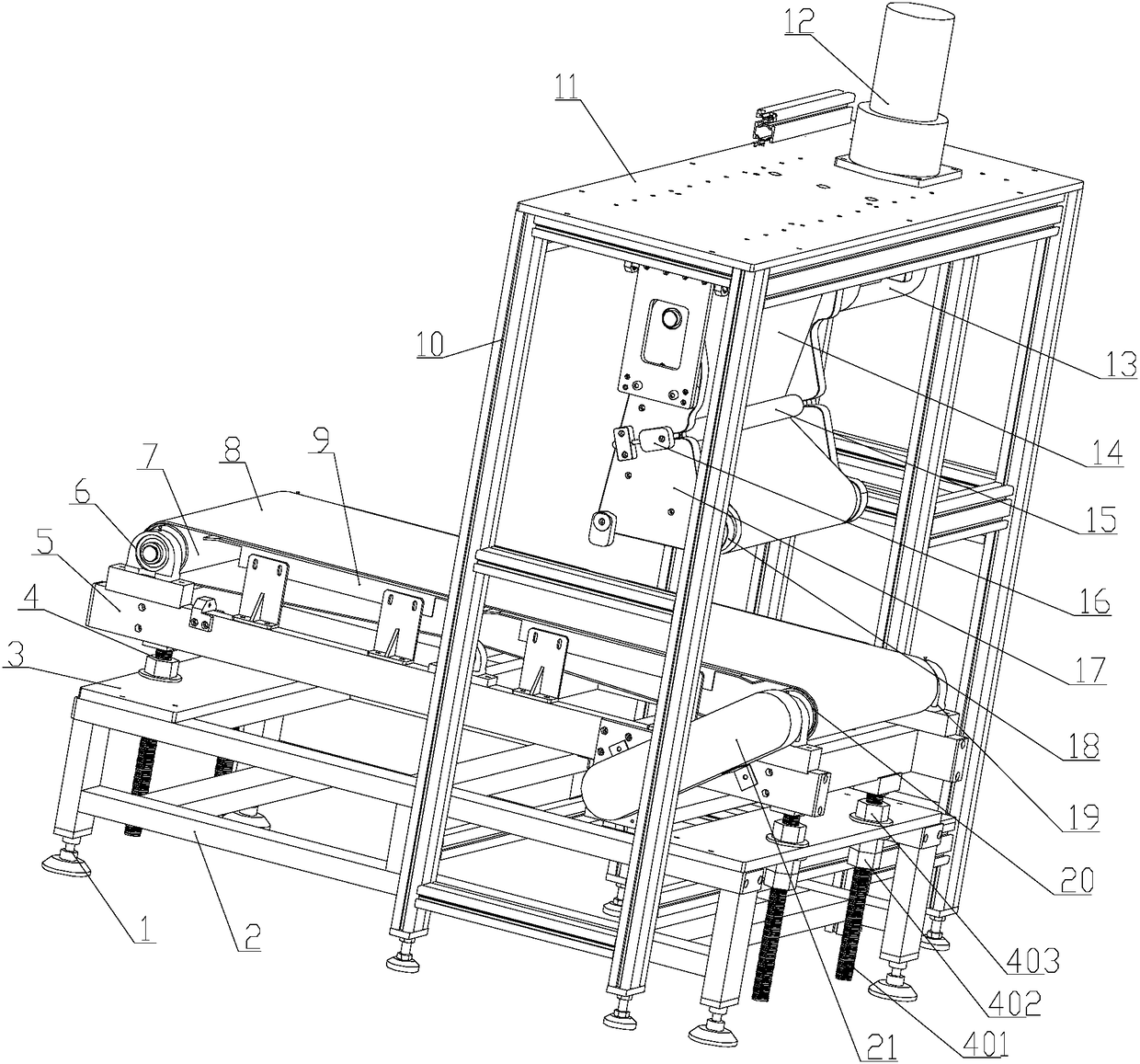

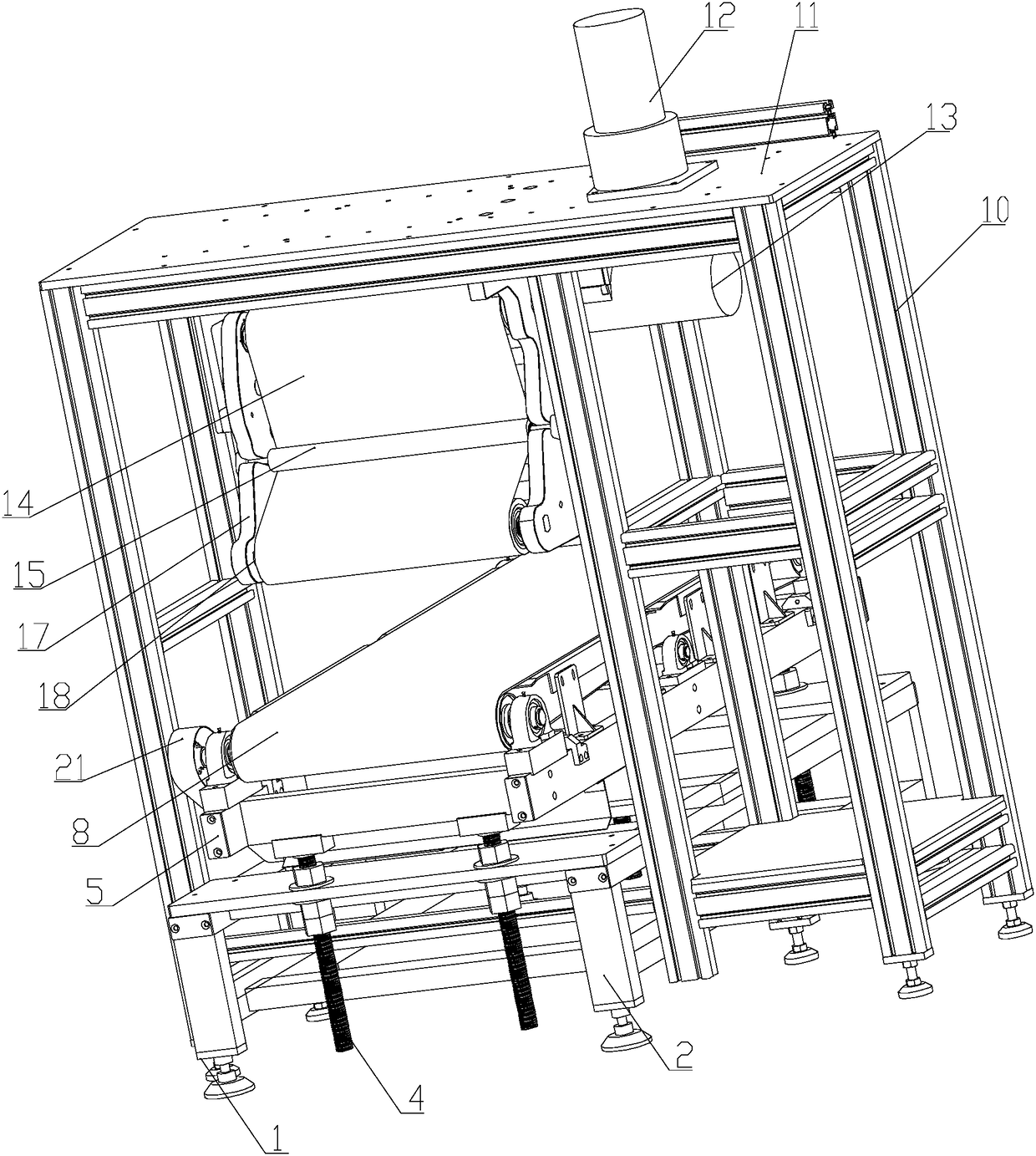

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1-2 , a kind of derusting polishing equipment for steel, it comprises frame 2, and the bottom of described frame 2 is equipped with adjustable leg 1, and the top of described frame 2 is supported by support platform 3 and is installed with steel plate delivery mechanism, A screw height adjusting device 4 is installed between the steel plate conveying mechanism and the support platform 3, and a top plate 11 is supported and installed above the steel plate conveying mechanism by a top bracket 10, and a derusting mechanism is fixedly installed on the top plate 11.

[0021] Further, the steel plate conveying mechanism includes a conveyor belt 8, a driven idler 7 is installed at one end of the conveyor belt 8, and a driving idler 20 is installed at the other end, and the driven idler 7 passes through the first bearing seat 6 Support is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com