Control system and control method of picking manipulator

A control system and manipulator technology, applied in the direction of picking machines, manipulators, program-controlled manipulators, etc., can solve problems such as inconvenient debugging of manipulator grasping posture, unstable start and stop characteristics of motors, and affecting the economic value of fruits and vegetables, so as to improve the quality of picking and efficiency, shortened debugging time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing, the present invention will be further described:

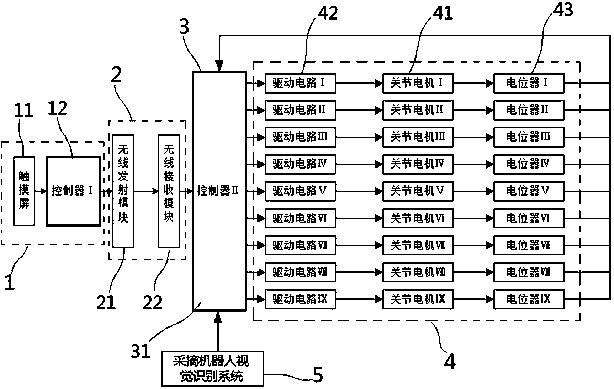

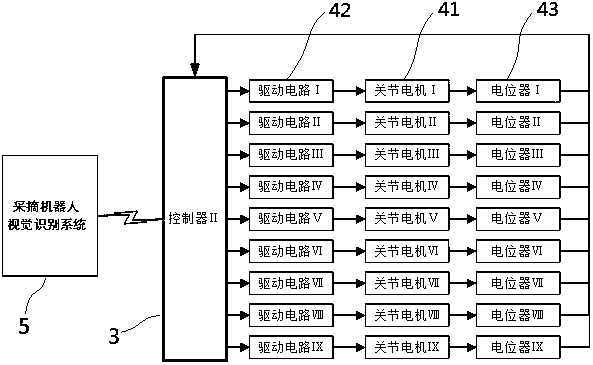

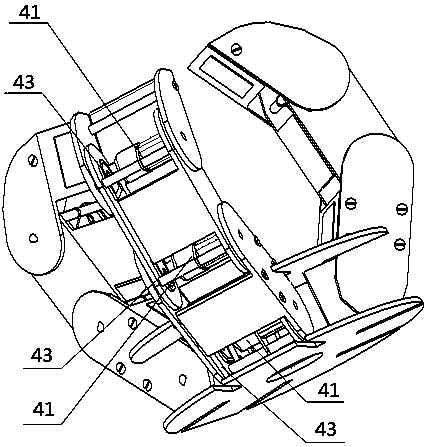

[0041] Figure 1 to Figure 4 An embodiment of the picking manipulator control system of the present invention is shown. figure 1 It is a structural schematic diagram of the picking manipulator control system in this embodiment.

[0042] Such as figure 1 As shown, the picking manipulator control system in this embodiment includes a host computer 1, a lower computer 3, a knuckle motor control module 4 and a visual recognition system 5, and a transmission module 2 is arranged between the upper computer 1 and the lower computer 3; Machine 3 is connected with knuckle motor control module 4 and visual recognition system 5 respectively.

[0043] The upper computer 1, according to the shape and size of different kinds of fruits and vegetables, virtual debugs various optimal grasping postures of the manipulator 7, and transmits them to the lower computer 3 through the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com